Application of Lab Coating Scraper Machine on Nonwoven Fabric

Summary:

As an important functional material, non-woven fabrics are widely used in medical, sanitation, home furnishing, clothing and other fields. In order to meet the needs of different application scenarios, it is often necessary to coat a layer of glue on the surface of non-woven fabrics to achieve waterproof, dustproof, antibacterial and other functions. This article conducts an experimental study of gluing on non-woven fabrics based on a laboratory scraper, discusses the impact of gluing process parameters on the gluing effect, and shares some experimental skills and experiences.

I. Introduction

Non-woven fabrics have excellent properties such as softness, breathability, moisture absorption, and waterproofing, and are widely used in various fields. However, in practical applications, in order to enhance the functionality of non-woven fabrics, it is often necessary to coat the surface with a layer of glue to achieve waterproof, dustproof, antibacterial and other functions. As a commonly used coating equipment, the laboratory scraper has the advantages of high glue coating accuracy and easy operation, and is suitable for coating non-woven fabrics.

2. Experimental design

Experimental material preparation: Select common non-woven fabric samples as experimental materials, and choose different types and brands of glue as coating materials.

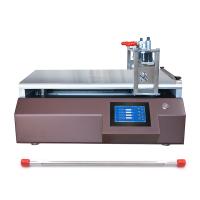

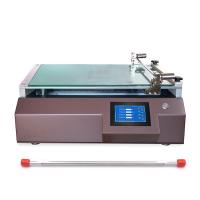

Experimental device: A laboratory scraper is selected as the coating equipment, equipped with a glue coating system, a scraper system, a drying system, etc., to realize the glue coating treatment of non-woven fabrics.

Experimental steps:

Cut the non-woven fabric to the desired size and clean the surface to remove impurities.

According to the experimental requirements, set the glue coating speed, scraper pressure, glue thickness and other parameters of the scraper.

Place the non-woven fabric on the squeegee machine, start the squeegee machine to conduct the glue coating experiment, and record the parameters and results during the glue coating process.

According to the gluing effect and experimental data, the influence of gluing process parameters on the gluing effect is analyzed, and the performance and stability of the scraper are evaluated.

3. Experimental results and analysis

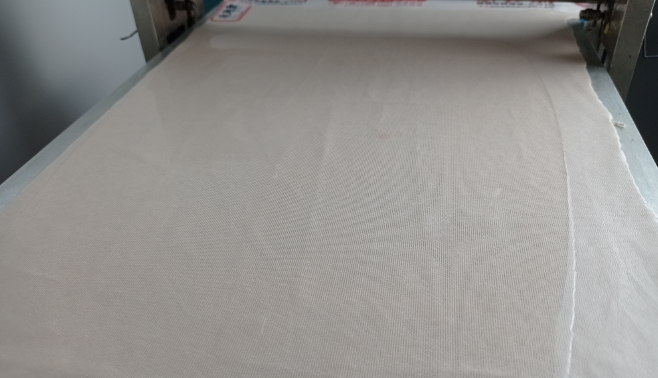

Glue coating effect: After the glue coating experiment, a glue layer evenly coated on the surface of the non-woven fabric was obtained. The thickness and uniformity of the glue were good, and the glue coating effect was in line with expectations.

Influence of gluing parameters: Experimental results show that parameters such as gluing speed, scraper pressure and gluing thickness have a significant impact on the gluing effect. Reasonable setting of gluing parameters can achieve better gluing effects.

Experimental skills and experience:

Choose the right glue: According to the material and application scenario of the non-woven fabric, choose the appropriate glue type and brand to ensure the glue effect and performance.

Adjust gluing parameters: During the experiment, adjust parameters such as gluing speed, scraper pressure, and gluing thickness according to actual conditions to ensure gluing effect and consistency.

Pay attention to cleaning and maintenance: Clean the gluing system and scraper system of the scraper regularly to keep the equipment clean and stable and avoid impurities and pollution from affecting the gluing effect.

4. Conclusion

This article conducts experimental research on coating glue on non-woven fabrics based on a laboratory scraper, discusses the impact of glue coating process parameters on the glue coating effect, and shares some experimental skills and experiences. Experimental results show that the laboratory scraper has the potential and application value to apply glue on non-woven fabrics, and can achieve precise control and high efficiency of the glue coating process.

- 1Scraping machine selection case: film substrate large size high accuracy scraping solution

- 2Application Case of Experimental Scraping Machine Coating Polymer on Non-woven Fabric [Video Demonstration]

- 3Application and Optimization Technology of Automatic Draw-Down Applicator in Preparative Polyester Film

- 4Three Methods of Preparative Unsupported Adhesive Film on Plastic Plate

- 5Laboratory film coating machine case | Automatic scraping and gluing on sponge 2mm