Screen Protector Preparative and Film Applicator Application Analysis

In modern society, with the popularity and wide application of electronic products, screen protectors, as an important accessory, are widely used on the displays of various smart devices, such as mobile phones, tablets, TVs, etc. Screen protectors can effectively protect the screen from scratches, fingerprints and other damage and extend the service life of the device, so its preparation process and quality control are particularly important. This article will describe the screen protector preparation process and the application of optional Film Applicator types.

1. Screen Protector Preparation Process

The preparation process of screen protector mainly includes the following steps:

1.1 Material preparation

The main materials for preparing screen protectors include plastic materials such as polycarbonate (PC), polyester (PET), and appropriate coating materials. These materials need to be prepared in advance and ensure that their quality meets the requirements.

1.2 Printing pattern design

Screen protectors are usually printed with various graphics, such as brand logos, anti-glare coatings, etc. During the preparation process, these patterns need to be designed and printed on the membrane using printing technology.

1.3 Coating treatment

The coating is a key part of the screen protector, providing protection and enhancement. Common coatings include anti-scratch coating, anti-fingerprint coating, anti-glare coating, etc. Coating treatment requires the use of special equipment and processes to ensure the uniformity and quality of the coating.

1.4 Cutting and packaging

The prepared screen protector needs to be cut and packaged to match different models of devices. This step requires sophisticated equipment and technology to ensure that the size and shape of the film meet the requirements and can effectively protect the screen.

2. Applications of optional film coating machine types

The film coating machine is one of the key equipment in the process of preparing screen protective film. It can achieve uniform application and solidification of the coating, improving production efficiency and product quality. The following introduces several common types of film coating machines and their applications:

2.1 Coating film coating machine

The coating film coating machine uses a coating process to evenly coat the coating on the surface of the substrate through a wire rod or a scraper. This coating machine is suitable for general coating thicknesses and can achieve high production speed and coating quality.

2.2 Ion beam sputtering coating machine

The ion beam sputtering coating machine uses ion beam sputtering technology to evaporate and deposit the coating material on the surface of the substrate in a vacuum environment. This coating machine is capable of achieving very thin coatings with good adhesion and optical properties, making it suitable for the preparation of high-end screen protectors.

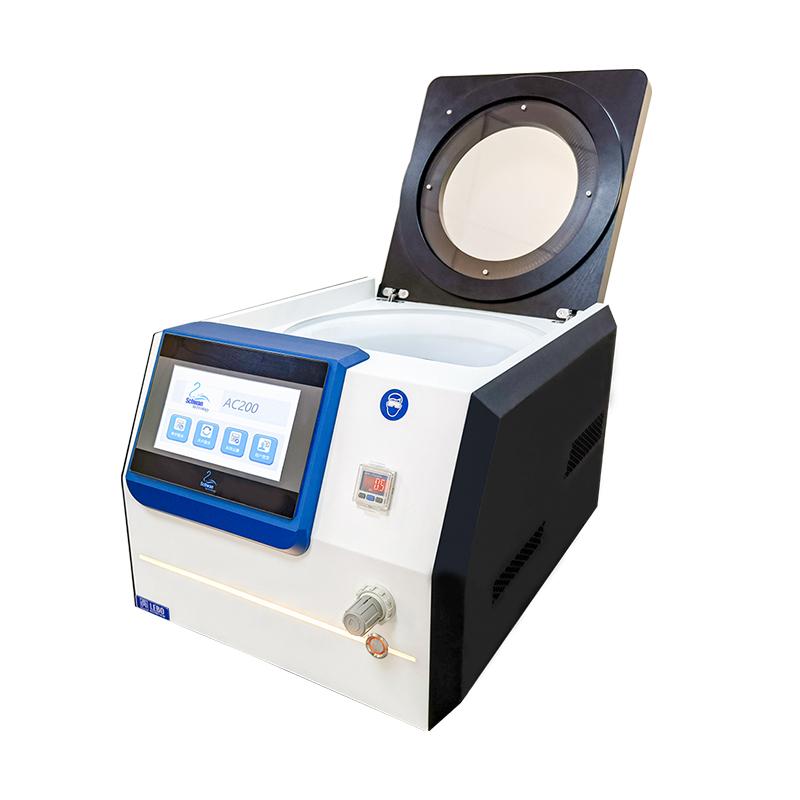

2.3 Spin coating machine

The spin coating machine uses the spin coating process to evenly coat the coating on the surface of the substrate by rotating the substrate and spraying the coating. This kind of coating machine is suitable for thin coating thickness, can achieve high-precision coating control, and is widely used in the preparation of screen protective films.

2.4 Laser etching coating machine

The laser etching coating machine uses laser etching technology to etch the required patterns and structures on the surface of the substrate. This coating machine can achieve very detailed pattern design, has high processing accuracy and good controllability, and is suitable for the production of high-end customized screen protection films.

Conclusion

The preparation process of screen protective film involves many links, and the film coating machine, as one of the key equipment, plays an important role in improving production efficiency and product quality. Different types of film coating machines have their own characteristics and application ranges. Manufacturers can choose the appropriate film coating machine model according to their needs to achieve a higher level of screen protection film preparation. With the continuous development and advancement of science and technology, I believe that film coating machine technology will continue to innovate and improve, providing more reliable and efficient solutions for the preparation of screen protective films.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Laboratory Automatic Film Applicator in Coating Battery Slurry on Copper Foil and Aluminum Foil

- 8Application of Film Applicator in PEM Research and Preparation

- 9Application of Film Applicator in PVDF-HFP Material Research