Effect of coated Vaseline on sponge performance: Application and analysis of Film Applicator Technology

Summary:

This experiment aims to explore the impact of the coating process on the performance of the sponge by using a coating machine to coat Vaseline on the surface of the sponge. In the experiment, we used film coating machine technology to regulate the coating effect by controlling coating parameters, such as coating speed, coating thickness, etc. By testing the water absorption performance, permeability performance and surface characteristics of the sponge, the impact of petroleum jelly coating on the performance of the sponge was analyzed.

introduction:

Sponge is a common porous material with good water absorption and penetration properties. However, in some specific application scenarios, the surface of the sponge needs to be treated to change its characteristics. Vaseline is a commonly used lubricant that is widely used in medical, cosmetics and other fields. Therefore, applying petroleum jelly to the surface of a sponge may change its properties and make it more useful. This experiment aims to explore the impact of the coating process on the performance of the sponge by using a coating machine to coat Vaseline on the surface of the sponge.

Materials and Methods:

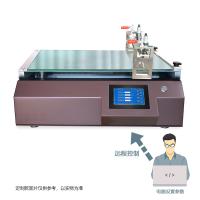

Materials: Sponge sample, Vaseline, Film Applicator.

Experimental steps:

Prepare the sponge sample, making sure its surface is clean.

Add an appropriate amount of Vaseline to the coating machine and adjust the parameters of the coating machine, such as coating speed, coating thickness, etc.

Place the sponge sample on the workbench of the film coating machine and start the coating machine for coating.

Adjust the coating parameters, observe the coating effect, and make adjustments as needed.

Remove the coated sponge sample for subsequent testing and analysis.

Experimental results and discussion:

After the sponge sample was coated with Vaseline, the surface showed a smooth touch, which was significantly different from the uncoated sponge.

The coating parameters were adjusted and it was found that the coating speed had a greater impact on the coating thickness. Applying too quickly will result in uneven coating, while applying too slowly will increase application time.

The water absorption performance test results of the sponge samples showed that the water absorption speed of the sponge coated with Vaseline was slightly lower than that of the uncoated sponge. This may be due to the petroleum jelly forming a barrier layer on the surface of the sponge, which slows down the penetration of water.

The permeability test results show that the permeability of the sponge to liquids after being coated with Vaseline is reduced, indicating that the coating process affects the permeability of the sponge.

Surface property test results show that the surface of the sponge coated with Vaseline has a certain degree of hydrophobicity and has good resistance to moisture from water droplets.

Conclusion

Through this experiment, we successfully used a coating machine to coat Vaseline on the sponge surface and analyzed the coating effect. Experimental results show that Vaseline coating changes the surface properties of the sponge, making it hydrophobic, but also reduces its water absorption and permeability. This provides a reference for the modification of sponges in some specific application scenarios, and also provides certain guidance for the optimization of the coating process.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application of laboratory coater in LED fluorescent film Spreader

- 4Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 5Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 6Application and selection of laboratory coater in PDMS thin film prepative

- 7Scraping machine selection case: film substrate large size high accuracy scraping solution

- 8Application of Film Applicator in PEM Research and Preparation

- 9Application of Film Applicator in PVDF-HFP Material Research