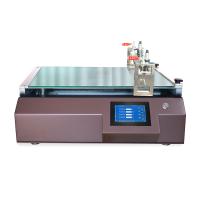

Selection Experiment of Small coater in PVC gel membrane prepative

Summary:

This experiment aims to evaluate the performance of different types of small coaters in the preparation of PVC gel films and select the most suitable coater model. We tested parameters such as coating uniformity, coating speed and film quality during the preparation process of PVC gel film using different models of coating machines to determine a good selection solution. Experimental results show that the coating machine model has a significant impact on the coating effect during the preparation process of PVC gel film. Choosing a suitable coating machine is crucial to the quality and production efficiency of the film.

introduction:

PVC gel film is a common plastic film material with good flexibility and transparency. It is widely used in packaging, construction, medical and other fields. The small coating machine is one of the key equipments for preparing PVC gel film. Its coating effect directly affects the quality and production efficiency of the film. Therefore, choosing a suitable small coater is crucial for PVC gel film preparation. This experiment aims to compare the performance of different models of small coaters in the preparation of PVC gel membranes, select the best coater model, and provide technical support and reference for the membrane preparation process.

Materials and Methods:

Materials: PVC gel film raw materials, different models of small coating machines.

Experimental steps:

Prepare PVC gel membrane raw materials to ensure stable quality.

Connect different models of small coaters with PVC gel film preparation equipment.

Set the parameters of the coating machine separately, including coating speed, coating thickness, temperature, etc.

Start the coater to prepare the PVC gel film for coating.

Conduct performance tests on the prepared films, including coating uniformity, transparency, flexibility and other indicators.

Analyze the impact of different coater models on the film preparation process and film performance.

Experimental results and discussion:

There are differences in the coating effects of different models of small coaters during the preparation process of PVC gel film. Some coaters have higher coating speeds, but this may result in uneven coating; while other coaters have slower coating speeds, but the coating effect is more uniform.

The coating thickness adjustment performance of the coater has an important impact on the quality and performance of the film. Some coating machines have a more flexible coating thickness adjustment function that can meet film preparation with different thickness requirements.

Experimental results show that selecting a suitable coater can significantly improve the preparation efficiency and quality of PVC gel film. The choice of coating machine model should be comprehensively considered based on specific needs and production scale.

Conclusion

Through this experiment, we evaluated the performance of different models of small coaters in the preparation of PVC gel films and selected the most suitable coater model. Experimental results show that the selection of a suitable coating machine has an important impact on the preparation efficiency and quality of PVC gel film. In future industrial production, appropriate coating machine models should be selected based on specific needs and production scale to improve production efficiency and product quality.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Experimental Study on High Viscosity Ultraviolet Resin Coating on Glass Substrate by Small Coater

- 3Application of doctor blade coater in electrode and solid electrolysis preparation

- 4Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 5Experimental application of water-based paints on film laminating paper by laboratory coater

- 6Laboratory small coater coated with polyester film on ultra-thin PET film [video demonstration]

- 7Technical Requirements and Application of Lithium Battery Slurry Coated on Copper Foil for Small Coater

- 8Application of small coater in gel coating

- 9Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane