Automatic Film Applicator Application of UV Adhesive on Silicon Wafer [Video Demonstration]

In recent years, the electronics industry has developed vigorously, and silicon wafers, as one of the important materials, are widely used in semiconductor manufacturing, photovoltaic cells, display devices and other fields. In order to pursue higher quality products, we are constantly optimizing and improving product functions and performance. Therefore, many researchers have conducted relevant experimental studies to study how to improve the performance and functionality of silicon wafers, which often requires coating a layer of UV glue on the surface. Compared with manual film production, automatic film coating machines can provide higher coating precision and ensure the accuracy of experimental research results.

Coating UV glue on a silicon wafer can improve the transparency, refractive index and other optical properties of the silicon wafer, making it more suitable for optical devices or optical applications. UV glue can provide an insulating layer to prevent silicon wafers on electronic devices from electrical interference or battery penetration. In some applications, coating with UV glue can be used to fix the connection or encapsulation between the silicon wafer and other components to enhance its structural stability and reliability.

![Application of UV glue on silicon wafer by automatic coating machine [Video demonstration] with picture 1](https://img.nbchao.com/upload/editor/image/20240313/1710297307077059527.png)

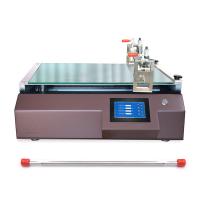

The customer's request for sending samples in this issue is to scrape and apply UV glue on the silicon wafer. Letâs first take a look at which machine model is suitable for the application needs of this kind of coating film. Since both the silicon wafer and the glue are transparent, kraft paper is also prepared to be placed under the silicon wafer to facilitate viewing of the coating effect. The viscosity of UV glue is not very high, so the accuracy of scraping with a wire bar applicator will be higher. The customer's coating film requirement is about 6.9μm thickness, so RDS No. 3 rod is used for scraping. Kraft paper is thin paper, so it is better to use vacuum adsorption to fix it. Therefore, a wire rod vacuum adsorption automatic film coating machine was used for this experiment.

The following is a video of the specific experimental process. Note that the glue has relatively strong fluidity, so the glue is added while scraping. If you want to save trouble, you can use the automatic feeding type to control the automatic glue dispensing.

From the video, the final coating effect is in line with the customer's needs. The coating is uniform and the thickness is within the expected range.

![Application of automatic coating machine to apply UV glue on silicon wafer [Video demonstration] with picture 2](http://img.nbchao.com/upload/editor/image/20240313/1710297350711074660.png)

![Application of UV glue on silicon wafer by automatic coating machine [Video demonstration] with picture 3](http://img.nbchao.com/upload/editor/image/20240313/1710297382681036966.png)

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application of laboratory coater in LED fluorescent film Spreader

- 4Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 5Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 6Application and selection of laboratory coater in PDMS thin film prepative

- 7Scraping machine selection case: film substrate large size high accuracy scraping solution

- 8Application of Film Applicator in PEM Research and Preparation

- 9Application of Film Applicator in PVDF-HFP Material Research