In-depth analysis of small coil coater technology and selection points

Summary

As a piece of equipment widely used in industrial production, small coil coaters have unique technical characteristics and a wide range of application fields. This article will introduce the working principle and structural characteristics of the small coil coating machine in detail, while discussing its differences from ordinary small coating machines, and providing key points for selection to help users better understand, select and operate this machine. critical equipment.

Working principle and structural characteristics of small coil coating machine

working principle

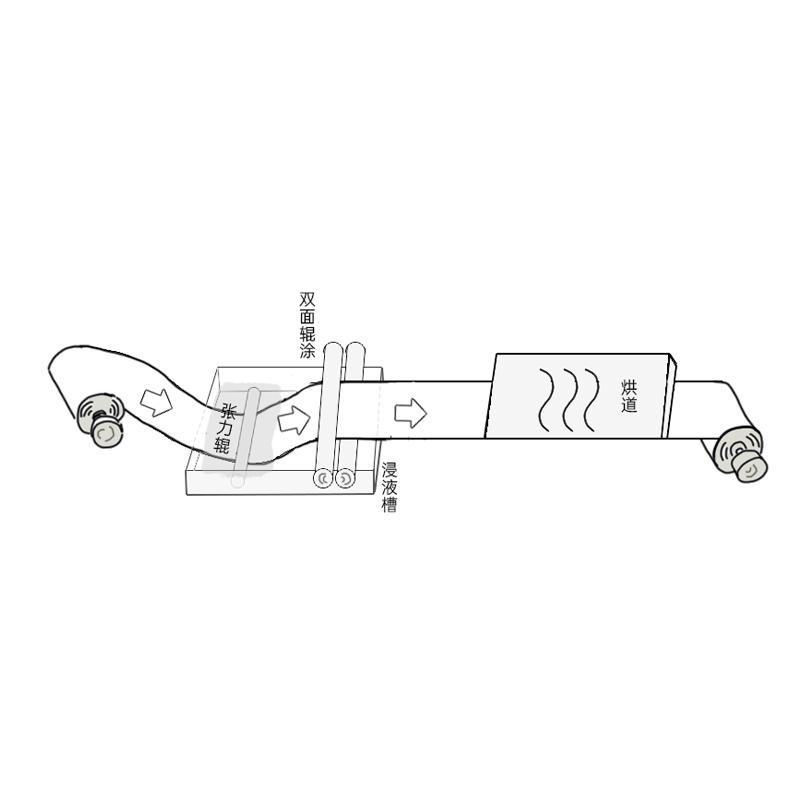

The small coil coating machine is mainly composed of a coating roller, a coil transmission system, a coating system, etc. Its working principle is to evenly coat the coating material on the surface of the coil through the coating roller. Through the drive system of the coil, the uniformity and consistency of coating are ensured.

Structural features

Compared with ordinary small coating machines, small coil coating machines have some unique features in structure. Common structural features include:

The web drive system is designed to accommodate different web widths and thicknesses.

The coating system is specially designed to ensure that the coating material evenly covers the surface of the coil.

Compact overall structure, easy to install and operate in limited space.

Comparison between small coil coating machine and ordinary small coating machine

1. Scope of application

Small coil coating machines are mainly used for coating coil materials, such as paper, film, metal coils, etc. Ordinary small coaters are more versatile and can be coated on various flat materials such as plates, films, and papers.

2. Structural design

The structural design of small coil coating machines focuses more on the special needs of coils, such as coil drive systems and coil centering adjustment systems. Ordinary small coaters pay more attention to the flatness of the coating roller and the smooth transportation of the material.

3. Convenience of operation

Small coil coaters are usually designed with a compact structure to facilitate operation in limited spaces and are suitable for coil production lines. Ordinary small-scale coating machines are more suitable for small-area coating needs of various materials, and the operation is more flexible.

Key points for selection

Coil properties

When choosing a small coil coater, you must first consider the characteristics of the coil, including width, thickness, material type, etc. Make sure the equipment selected can meet the specific requirements of the web.

coating material

Different coating materials have different requirements for coating machines. Therefore, the viscosity, fluidity and other characteristics of the required coating materials should be considered when selecting to ensure that the equipment can effectively coat.

Production efficiency needs

Select the appropriate coating speed and production capacity according to the actual needs of the production line. Make sure the small coil coater you choose can meet production efficiency requirements.

Ease of operation and maintenance

Consider the ease of operation and maintenance of the equipment and choose a small coil coater that is easy to operate and maintain to improve production efficiency and reduce operating costs.

Conclusion

As a kind of equipment specially designed for coil coating, the small coil coating machine has unique characteristics in structural design and application range. When selecting, users need to comprehensively consider the working principle, structural characteristics, and ease of operation and maintenance of the equipment based on specific production needs and material characteristics. Through scientific and reasonable selection, users can better cope with different production scenarios, improve production efficiency, and ensure product quality.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Experimental Study on High Viscosity Ultraviolet Resin Coating on Glass Substrate by Small Coater

- 3Application of doctor blade coater in electrode and solid electrolysis preparation

- 4Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 5Experimental application of water-based paints on film laminating paper by laboratory coater

- 6Laboratory small coater coated with polyester film on ultra-thin PET film [video demonstration]

- 7Technical Requirements and Application of Lithium Battery Slurry Coated on Copper Foil for Small Coater

- 8Systematic understanding of coil isolation film coater

- 9Application of small coater in gel coating