Application and precautions of laboratory coater in preparation of solder paste

With the rapid development of the electronics industry, Surface Mount Technology (SMT) plays a vital role in electronic manufacturing. In the SMT process, solder paste is a key soldering material, and the coating technology during its preparation is particularly important. This article will delve into the application of laboratory coaters in solder paste preparation, coating precautions and how to choose a suitable solder paste coating machine.

Application of laboratory coater in solder paste preparation

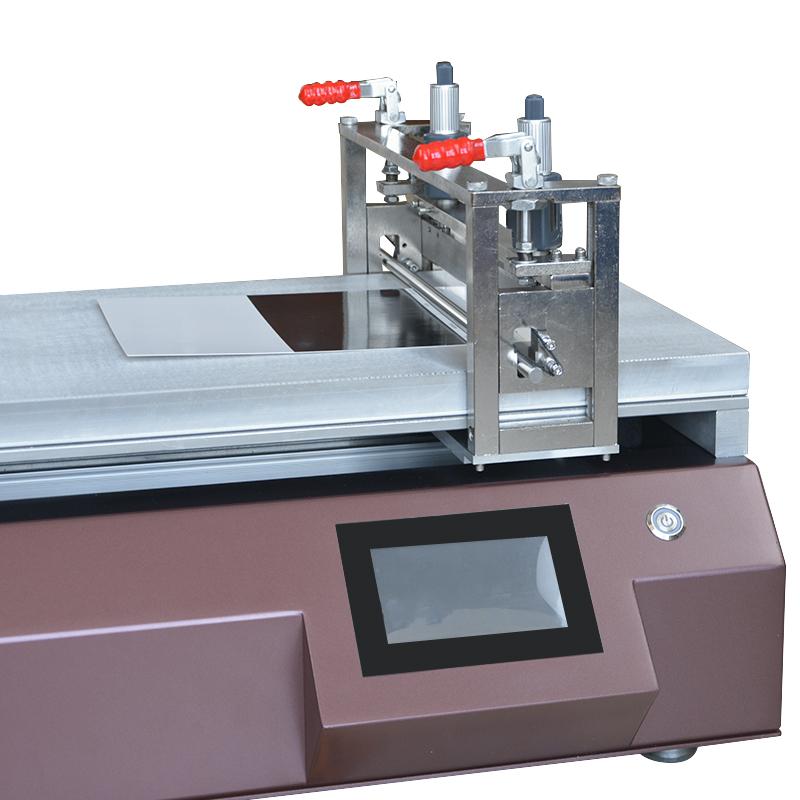

The laboratory coater is a device used to evenly coat liquid materials on the surface of the substrate. It plays an important role in solder paste preparation. It mainly includes the following aspects:

The laboratory coater ensures uniform coating of solder paste on the surface of the substrate by accurately controlling coating parameters, such as coating speed, coating pressure and coating angle, thereby ensuring the stability and reliability of welding quality.

The laboratory coating machine has a high degree of automation and production efficiency, enabling a continuous and stable production process. Compared with manual coating, laboratory coating machines can greatly improve coating efficiency, reduce production costs, and reduce operator errors and labor intensity.

The laboratory coater has a large coating range and adjustable parameter range, and can adapt to the preparation of solder paste with different specifications and requirements. Operators can adjust coating parameters according to specific needs to achieve flexible control and adjustment of the solder paste coating process.

Laboratory coaters are usually equipped with accurate coating parameter recording and management systems, which can accurately manage and record different solder paste formulas to ensure the traceability of the production process and the stability of production quality.

Precautions for coating

When using a laboratory coater for solder paste preparation, you need to pay attention to the following:

Substrate preparation: Before coating, the substrate needs to be cleaned and pre-treated to ensure that the surface of the substrate is clean and dust-free to improve the solder paste adhesion and welding quality.

Coating parameter adjustment: Coating parameters, including coating speed, pressure, angle, etc., need to be reasonably adjusted according to the characteristics and requirements of the solder paste to ensure that the coating thickness and uniformity meet the requirements.

Coating environment control: During the coating process, it is necessary to maintain the stability of the coating environment, including the control of parameters such as temperature, humidity, and wind speed, to ensure the stability and consistency of coating quality.

Equipment maintenance: Clean and maintain the laboratory coating machine regularly to maintain the normal operation of the equipment and extend the service life of the equipment. At the same time, pay attention to the safe operation of the coating machine.

How to choose a suitable solder paste coating machine

When choosing a suitable solder paste coating machine, you can consider the following factors:

The coating width, coating speed, coating thickness range and other parameters of the coating machine are selected according to the production scale and coating requirements.

Pay attention to the coating accuracy, stability, adjustability and other technical performance of the coating machine to ensure that the coating quality meets the requirements.

Evaluate the production efficiency and automation level of the coating machine and select equipment that can meet production needs and improve production efficiency.

Choose a coating machine supplier with reliable after-sales service and technical support to ensure the normal operation and maintenance of the equipment.

Conclusion

Laboratory coaters play a key role in solder paste preparation. Through precise coating technology and reasonable control of precautions, the quality and production efficiency of solder paste can be improved, thus promoting the development and progress of the electronic manufacturing industry. Choosing a suitable coating machine and strictly controlling the parameters and environment during the coating process will help improve the quality and reliability of solder paste preparation and meet the demand for high-quality soldering materials for electronic products.

- 1Application of laboratory coater in LED fluorescent film Spreader

- 2Application and selection of laboratory coater in PDMS thin film prepative

- 3Application of doctor blade coater in electrode and solid electrolysis preparation

- 4Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 5Experimental application of water-based paints on film laminating paper by laboratory coater

- 6Experimental coater application case video of liquid silica gel on release paper

- 7Laboratory small coater coated with polyester film on ultra-thin PET film [video demonstration]

- 8Application of small coater in gel coating

- 9Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane