Overview of waterproofing membrane plaster coater technology

introduction:

Waterproof membrane is a commonly used waterproof material in the construction field. It can effectively prevent moisture penetration and protect the building structure from moisture and corrosion. As a key equipment in the production and manufacturing process, the waterproof membrane plaster coating machine has a direct impact on the quality and performance of the membrane waterproof material. This article will review the technical characteristics, working principles, development trends, etc. of waterproof roll plaster coating machines, with a view to providing certain reference for research and application in this field.

1. Technical characteristics of waterproof roll plaster coating machine

1.1 High-precision coating technology

The waterproof membrane plaster coating machine adopts advanced coating technology and has high-precision coating capabilities. Through the precise control system and intelligent operating interface, key parameters such as coating thickness and uniformity can be accurately controlled to ensure the quality stability of coil coating.

1.2 Multifunctional coating capabilities

Modern waterproof membrane plaster coating machines can not only coat basic waterproof plaster materials, but also have multi-functional coating capabilities. For example, some advanced coating machines can add additional functional materials such as fire protection and anti-corrosion to the surface of the coil to improve the overall performance of the coil and meet the needs of different construction projects.

1.3 Efficient production capacity

With the rapid development of the construction industry, the demand for waterproof membranes is also increasing. Therefore, the production capacity of the waterproof membrane plaster coating machine has been significantly improved. Efficient production capacity means faster production cycles and greater market competitiveness, bringing significant economic benefits to manufacturers.

1.4 Environmentally friendly and energy-saving design

In the context of the current increasing awareness of environmental protection, the design of waterproof roll plaster coating machines also pays more attention to environmental protection and energy saving. Use advanced materials and processes to reduce energy consumption, reduce waste generation, and achieve a green and environmentally friendly coating process through resource recycling in the production process.

2. Working principle of waterproof roll plaster coating machine

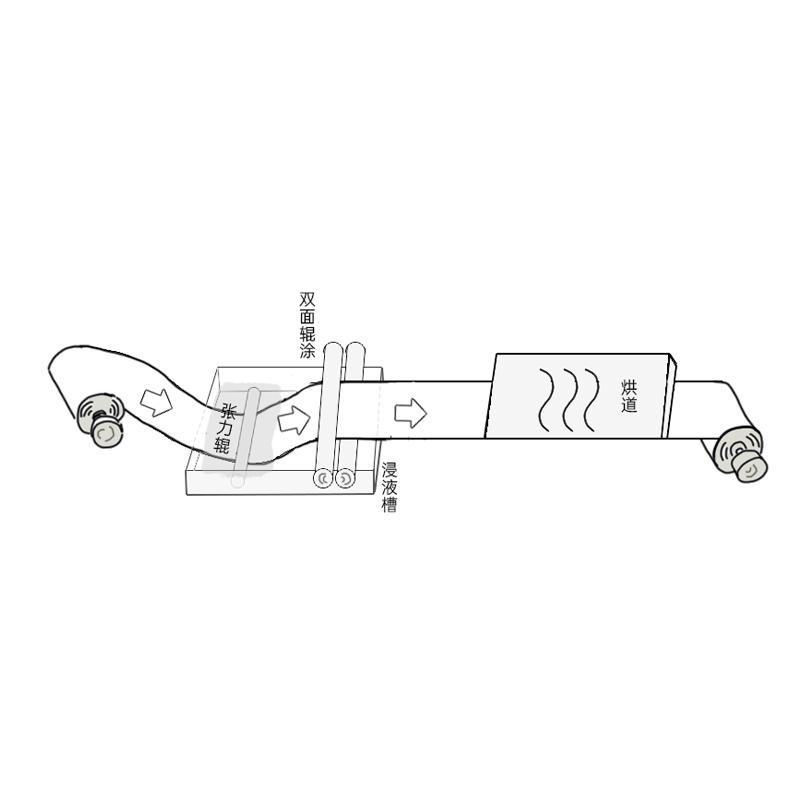

2.1 Material supply system

The working principle of the waterproof membrane plaster coating machine first involves the material supply system. Typically, waterproof plaster materials are loaded into the coater's material feed system in reels or sheets. Through precise tension control and roller transmission, a stable supply of waterproof materials is ensured.

2.2 Coating system

The coating system is the core part of the waterproof membrane plaster coating machine. It usually includes coating rollers, coating knives, coating roller drive systems and other components. During the coating process, the waterproof material is evenly coated on the surface of the substrate through the coating roller, and the coating knife plays a key role in controlling the coating thickness.

2.3 Drying system

After coating is completed, the waterproofing membrane needs to be cured through a drying system. Traditional drying systems usually use ovens to quickly solidify waterproof plaster materials through heating and ventilation to improve production efficiency. In recent years, some new coating machines have adopted ultraviolet curing technology to achieve a faster curing process.

2.4 Control system

The entire coating process requires a stable and intelligent control system to realize the coordinated work of all parts. The control system usually includes sensors, PLC controllers, human-machine interfaces and other components. Through real-time monitoring and adjustment, it ensures the stability and accuracy of various parameters during the coating process.

3. Development Trend of Waterproof Coiled Plaster Coating Machine

3.1 Intelligent technology application

With the continuous development of artificial intelligence and Internet of Things technology, waterproof roll plaster coating machines are gradually ushering in the era of intelligence. The intelligent control system can realize automatic optimization and intelligent management of the coating process through big data analysis, self-learning algorithms and other means, improving production efficiency and product quality.

3.2 Coating adaptability of new materials

With the continuous emergence of new building materials, waterproof membrane plaster coating machines need to have stronger coating adaptability. For different types of waterproof plaster materials, the coating machine should have flexible adjustment capabilities to meet the diverse needs in the market.

3.3 Application of environmental protection technology

Environmental protection has become an important trend in the development of the manufacturing industry, and waterproof membrane plaster coating machines are no exception. The future development direction will pay more attention to the application of environmentally friendly technologies, including technological innovations in wastewater treatment, exhaust gas emissions, etc., to reduce adverse effects on the environment.

3.4 Intelligent maintenance and remote monitoring

In order to improve the reliability of equipment and reduce maintenance costs, the development trend of waterproof membrane plaster coating machines also includes intelligent maintenance and remote monitoring. Real-time monitoring of equipment operating status through sensors, remote diagnosis and adjustment of equipment faults, and improvement of equipment stability and maintainability.

Conclusion

As an indispensable production equipment in the construction field, the waterproof membrane plaster coating machine's technical characteristics, working principles and future development trends are of great significance to improving the production efficiency and quality of waterproof membranes. With the continuous advancement of technology, I believe that waterproof membrane plaster coating machines will usher in more innovation and development in the future.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Application of doctor blade coater in electrode and solid electrolysis preparation

- 3Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 4Systematic understanding of coil isolation film coater

- 5Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 6The principle and application of miniature coil spraying machine

- 7Several Common Experimental Spreader Methods and Their Applications

- 8Application of laboratory coater coating aluminum oxide paste on PET film

- 9Experimental test of performance of epoxy resin film coated on metal iron plate by small coater