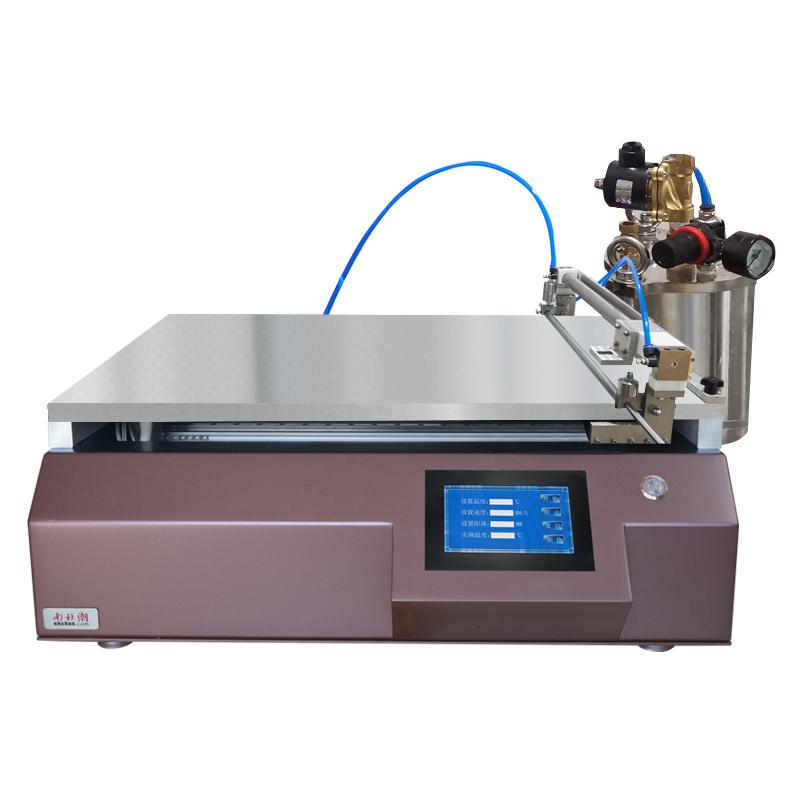

Adhesive Application Case of Coil Coater and Spreader Technology Introduction

Summary:

This article will delve into the importance of coil coaters in adhesive applications and their case applications in different industries. Through the detailed introduction of coating methods, readers will be able to more fully understand the technical characteristics and advantages of coil coating machines in the field of adhesives.

I. Introduction

Coil coater is a piece of equipment widely used in industrial production and plays a vital role in adhesive application. Adhesives play a key role in connecting, fixing and sealing during the manufacturing process, and the coil coater, as the main tool for applying adhesives, plays a decisive role in product quality and production efficiency.

2. Adhesive application cases of coil coater

2.1 Automobile manufacturing industry

In the automotive manufacturing industry, coil coaters are widely used in the manufacturing process of body parts. Adhesives are used in automobile manufacturing to join and seal body parts to ensure the strength and sealing of the vehicle structure. The coil coater can evenly cover the surface of the body parts with adhesive through precise coating methods, improving the firmness of the connection and ensuring the efficiency of the entire manufacturing process.

2.2 Packaging industry

In the packaging industry, coil coaters are widely used in the production process of various packaging materials. Adhesives play a role in sealing, fixing and protecting packaging. The coil coating machine can adapt to different types of packaging materials through different coating methods, ensuring even distribution of adhesive and improving the firmness and aesthetics of the packaging.

2.3 Construction industry

In the construction industry, coil coaters play an important role in the production of roof waterproofing materials. Adhesives are used to bond roofing membranes to ensure the waterproofing properties of the roof. The coil coater can form a uniform adhesive layer on the surface of the coil through a specific coating method, improving the waterproofing effect and extending the service life of the roof.

3. Technical introduction of coil coating machine coating methods

3.1 Blade coating method

The blade coating method is one of the common coating methods in coil coaters. In this method, the coater uses a scraper to evenly scrape the adhesive onto the surface of the roll to form a thin film. This coating method is simple and easy to operate, and is suitable for some occasions with lower requirements. However, due to the contact of the scraper, the problem of uneven adhesive coating may sometimes occur, so its application is limited in some fields that require high coating accuracy.

3.2 Roller coating method

Roller coating is a coating method that transfers adhesive to the surface of the roll through a roller. This method can achieve more precise coating control and is suitable for occasions that require high coating accuracy. The roller coating method can also achieve coating with different thicknesses and uniformities by adjusting the pressure and rotation speed of the roller, increasing the flexibility of coating.

3.3 Spray coating method

The spray coating method is a coating method in which the adhesive is sprayed evenly on the surface of the coil through a nozzle. This method is efficient and fast, and is suitable for some production occasions that require high coating speed. The spray coating method can achieve even coverage of adhesive on a large area of ââcoiled material, improving production efficiency. However, because the spray coating method requires high precision control of the nozzle and air pressure, it is relatively rarely used in some fields that require very high coating accuracy.

4. Conclusion

The use of coil coaters in adhesive applications shows that they play an irreplaceable role in different industries. By using different coating methods, the coil coater can adapt to the needs of various adhesives in different production situations, improving production efficiency and product quality. The blade coating method, the roller coating method and the spray coating method each have their own advantages and disadvantages. It is crucial to choose the appropriate coating method according to the specific production requirements.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Application of doctor blade coater in electrode and solid electrolysis preparation

- 3Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 4Systematic understanding of coil isolation film coater

- 5Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 6The principle and application of miniature coil spraying machine

- 7Several Common Experimental Spreader Methods and Their Applications

- 8Application of laboratory coater coating aluminum oxide paste on PET film

- 9Experimental test of performance of epoxy resin film coated on metal iron plate by small coater