Explore the technical principle, type and Spreader of Bopp hot-melt adhesive coater

Summary :

Bopp hot melt adhesive coating machine is a key industrial equipment used to evenly coat hot melt adhesive on Bopp film and is widely used in the packaging industry. This article deeply discusses the technical principles, different types and coating procedures of Bopp hot melt adhesive coating machines, aiming to fully understand the working mechanism and operating process of this key equipment.

1. Technical principles:

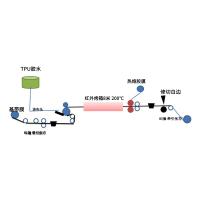

The working principle of the Bopp hot melt adhesive coating machine is based on the characteristics of hot melt adhesive and the mechanical transmission system. Its main components include: hot melt glue box, coating roller, heating system and control system.

Hot melt glue box: A hot melt glue box is a device for storing and heating hot melt glue. It is usually made of stainless steel and has good corrosion resistance and thermal conductivity. The hot melt adhesive is heated to a certain temperature in the box to make it flow.

Coating roller: The coating roller is a key component for evenly coating hot melt adhesive on the surface of Bopp film. The coating roller is usually made of metal, and its surface is precision machined to ensure uniformity and stability of coating.

Heating system: The heating system is used to heat the hot melt adhesive so that it reaches the appropriate temperature to maintain a flowing state. The heating system usually uses electric heating or steam heating, and the heating temperature is accurately adjusted through a temperature control system.

Control system: The control system is used to monitor and adjust various parameters of the coating machine, including hot melt adhesive temperature, coating speed, etc. Modern coating machines are usually equipped with advanced PLC control systems to achieve automated operation and remote monitoring.

2. Coating machine type:

According to the coating method and structural characteristics, Bopp hot melt adhesive coating machines can be divided into the following types:

Extrusion coater: The extrusion coater uses an extrusion device to squeeze the hot melt adhesive onto the surface of the coating roller, and the hot melt adhesive is evenly coated on the Bopp film through the coating roller. This coating machine has a simple structure and stable operation, and is suitable for small and medium-sized production.

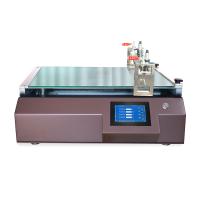

Blade coater: The blade coater uses a scraper to apply the hot melt adhesive on the surface of the coating roller, and then evenly coats the hot melt adhesive on the Bopp film through the coating roller. The blade coating machine has the characteristics of adjustable coating thickness and good coating uniformity, and is suitable for production with high precision requirements.

Roller-type coater: The roller-type coater uses a roller to apply hot melt adhesive on the surface of the Bopp film, and the coating is achieved through the rotation of the roller. This coating machine has a simple structure and is easy to operate, and is suitable for continuous mass production.

Spray coating machine: The spray coating machine uses a nozzle to spray hot melt adhesive on the surface of the Bopp film, and the coating is achieved by spraying. This kind of coating machine is suitable for coating processes with special requirements, such as partial coating, multi-color coating, etc.

3. Coating procedure:

The coating procedure of Bopp hot melt adhesive coating machine usually includes the following steps:

Preparation work: Before starting the coating machine, the equipment needs to be inspected and prepared, including checking whether the hot melt glue box has enough hot melt glue, checking whether the coating roller and heating system are working properly, etc.

Parameter setting: According to production requirements, set the relevant parameters of the coating machine, including hot melt adhesive temperature, coating speed, coating thickness, etc.

Start the coater: Start the coater according to the operating process, start the heating system to heat the hot melt adhesive to the set temperature, and then start the coating roller to coat the hot melt adhesive on the surface of the Bopp film.

Adjust parameters: Adjust the relevant parameters of the coating machine in real time according to the coating effect to ensure uniform and stable coating.

Monitor production: Continuously monitor the operating status of the coating machine, discover and solve problems in time, and ensure the smooth progress of production.

Shutdown and cleaning: After production, shut down the coating machine and perform cleaning and maintenance work, including cleaning residual hot melt adhesive, cleaning the coating roller, etc.

Conclusion

As a key packaging equipment, Bopp hot melt adhesive coating machine plays an important role in the packaging industry. An in-depth understanding of its technical principles, different types and coating procedures will help improve production efficiency and product quality, and promote the sustainable development of the packaging industry.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Application of doctor blade coater in electrode and solid electrolysis preparation

- 3Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 4Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 5Several Common Experimental Spreader Methods and Their Applications

- 6Application of laboratory coater coating aluminum oxide paste on PET film

- 7Experimental test of performance of epoxy resin film coated on metal iron plate by small coater

- 8Method and application of experimental coater coating water-based slurry on aluminum foil

- 9Application of wire rod coater in hydrogen battery separator prepative