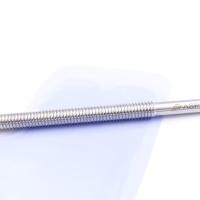

Introduction of 30μm Wet Film Applicator

In the paint production and coating process, wet film coating is a crucial link, and the 30μm wet Film Applicator is one of the key equipment to achieve precision coating. The 30μm wet Film Applicator is a device used to measure the thickness of the wet film formed by coating on the surface of the substrate. The principle is to control the coating quantity and quality of the coating by evenly coating a certain amount of coating on the surface of the substrate, and then measuring the thickness of the wet film using a measuring instrument (such as a thickness meter or optical measuring instrument).

Features

High precision: The 30μm wet Film Applicator has high-precision coating capabilities and can form a very uniform and precise wet film thickness on the surface of the substrate to ensure the quality and consistency of the coating.

Strong adjustability: The coating amount can be adjusted as needed, suitable for different types and requirements of coatings, to meet different process processes and product needs.

Easy to operate: The 30μm wet Film Applicator has a clear and simple operating interface, and operators can easily master and operate it without complex training.

High efficiency and energy saving: Using advanced coating technology and energy-saving design, it has the characteristics of high efficiency and energy saving, which can reduce the waste and cost of coating.

Stable and reliable: The 30μm wet Film Applicator adopts high-quality materials and precise processing technology, and has stable and reliable performance, ensuring the stability and reliability of production.

Application areas

30μm wet Film Applicators are widely used in various coating production and coating processes. For example, it is used in the coating process of automobile bodies, interiors and parts to ensure uniform coating and high-quality coating effects. The coating process used on furniture surfaces ensures even coating and smooth surface quality. It is used in the coating process of interior and exterior walls and decorative materials of buildings to ensure uniform coating and durability of the coating. The anti-corrosion coating process is used on the surface of the ship hull to ensure uniform coating and anti-corrosion effect.

As a key equipment in the coating production and coating process, the 30μm wet Film Applicator can ensure that the coating forms a precise wet film thickness on the surface of the substrate, ensuring the quality and consistency of the coating. The coating operation can be performed quickly, which improves production efficiency and reduces production costs. By accurately controlling the wet film thickness during the paint coating process, errors and variations in the production process are reduced, and production risks are reduced. Precision wet film coating can meet customers' high requirements for product quality and performance, improving the product's competitiveness and market share.

Conclusion

As an important equipment in the coating production and coating process, the 30μm wet Film Applicator plays an important role with its characteristics of precision coating, easy operation, high efficiency and energy saving. With the continuous development and technological advancement of the coating industry, 30μm wet Film Applicators will continue to play an important role in providing more precise and efficient coating services for coating production and coating processes.

- 1Wire Bar Applicator rod and wet Film Applicator difference video tells you

南北潮

- 2Difference Between Applicator Rod and Film Applicator

- 3Mayer Rods VS Film Applicators

- 4Differences Between Different Types of Film Applicators

- 5Several solutions for double coating

- 6What function types are available for the Nanbei Tide Experimental Small Coater?

- 7What are the models of popular bar applicators?

- 8Comparison of different brands of adjustable wet film preparers

- 9Tide Review: Adjustable Wet Film Coater ZUA2000.150