Perovskite solar cell preparatory method using solvent immersion resistant applicator

Summary:

This paper describes a novel perovskite solar cell preparation method that utilizes a piece of paper as an applicator to achieve high-quality perovskite film deposition in ambient air, even at low temperatures compatible with plastic substrates. Can achieve. By soaking paper applicators in the green anti-solvent ethyl acetate, the conversion efficiency of solar cells can be significantly increased. By studying PL, SEM and XRD analysis as well as photovoltage and current transients, the article verified that the double-cationic perovskite film prepared by this method has enhanced uniformity, crystallinity and better connectivity, as well as lower defect concentration. This method will not only help laboratories lacking sophisticated deposition technology, but also has the potential to be fully automated in large-scale manufacturing, paving the way for rapid industrialization of deposition methods.

introduction

Perovskite solar cells have attracted much attention due to their high efficiency and low cost. However, traditional preparation methods usually require complex equipment and special process conditions, limiting their large-scale application. Therefore, finding a simple and efficient preparation method is crucial for the further development of perovskite solar cells.

Method introduction

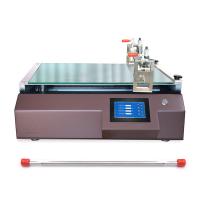

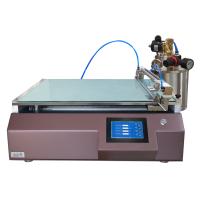

This article describes a method for preparing applicators that utilize anti-solvent soaking. This method uses a piece of paper as the applicator and soaks it in the green anti-solvent ethyl acetate. Subsequently, the bottom plate containing the perovskite precursor solution was covered and evenly coated on the bottom plate using a paper applicator soaked in antisolvent. Finally, the sample is dried at an appropriate temperature to form a perovskite film.

Results and discussion

It has been experimentally verified that perovskite films prepared using anti-solvent immersion applicators are superior to traditional preparation methods in terms of uniformity, crystallinity and defect concentration. Through the analysis of photovoltage and current transients, it was further verified that the solar cells prepared by this method have lower defect concentration, thereby improving the performance and stability of the cells.

Summarize

The preparation method of anti-solvent immersion applicators introduced in this article provides a simple and efficient new way to prepare perovskite solar cells. This method can not only be applied to laboratory-scale preparation, but is also expected to be fully automated in industrial production, providing new possibilities for large-scale applications of perovskite solar cells.

the data shows:

The conversion efficiency of solar cells prepared using dry applicators was 6.7%, while the conversion efficiency of solar cells prepared using paper applicators soaked in anti-solvent could be increased to 11.1%.

The perovskite film prepared by anti-solvent immersion applicator showed better crystal crystallinity in XRD analysis, and the half-maximum width of the (100) crystal plane decreased from 0.36 to 0.28, indicating fewer crystal defects.

Photovoltage and current transient analysis showed that solar cells prepared by anti-solvent immersion applicators had faster charge transfer and longer charge recombination lifetime, indicating more optimized morphology and crystallinity.

Steady-state photoluminescence (PL) spectroscopy shows that perovskite films prepared by solvent-resistant immersion applicators have better electron quality and lower non-radiative trap density.

Self-consistent photoelectric simulation results show that the defect state density of the perovskite film prepared by the solvent-resistant immersion applicator is significantly reduced, further proving its superiority.

In summary, the preparation method of anti-solvent immersion applicator provides a simple and efficient new way for the preparation of perovskite solar cells, and has good performance and stability, providing a new way for the industrial production of solar cells. possibility.

- 1Advantages of drawdown blade method in preparation of perovskite solar cells

- 2Comparison of advantages and disadvantages of preparing large area perovskite films by doctor blade Spreader method and spin coating method

- 3Perovskite Spreader Technology: Preparative Efficient Solar Cell Thin Film

- 4What are the functions of Perovskite Film Applicators?

- 5Application of Coating Machine in Perovskite Coating

- 6Perovskites could change the future of solar energy

Karen Frances Eng

- 7Preparation process of perovskite thin films

丁相宇 - 《长春理工大学》

- 8What is a perovskite material?

张勇 - 《武汉理工大学》