Epoxy coil coater technology and selection method

Summary:

Epoxy coil coaters are equipment widely used in construction, ships, automobiles and other fields. Its coating technology plays an important role in improving the weather resistance, corrosion resistance and aesthetics of materials. This article will discuss in detail the technical characteristics, selection methods, and adjustment of coating parameters of epoxy coil coaters to help readers better understand and apply this key equipment.

Part One: Overview of Epoxy Coil Coater

1.1 Technical background

The epoxy coil coater is a device specially used for coating epoxy coils. Its coating process is directly related to the quality and performance of the material. The development of coating machines is closely related to the increasing requirements for high performance, weather resistance and aesthetics in the construction, automobile, shipbuilding and other industries.

1.2 Technical features

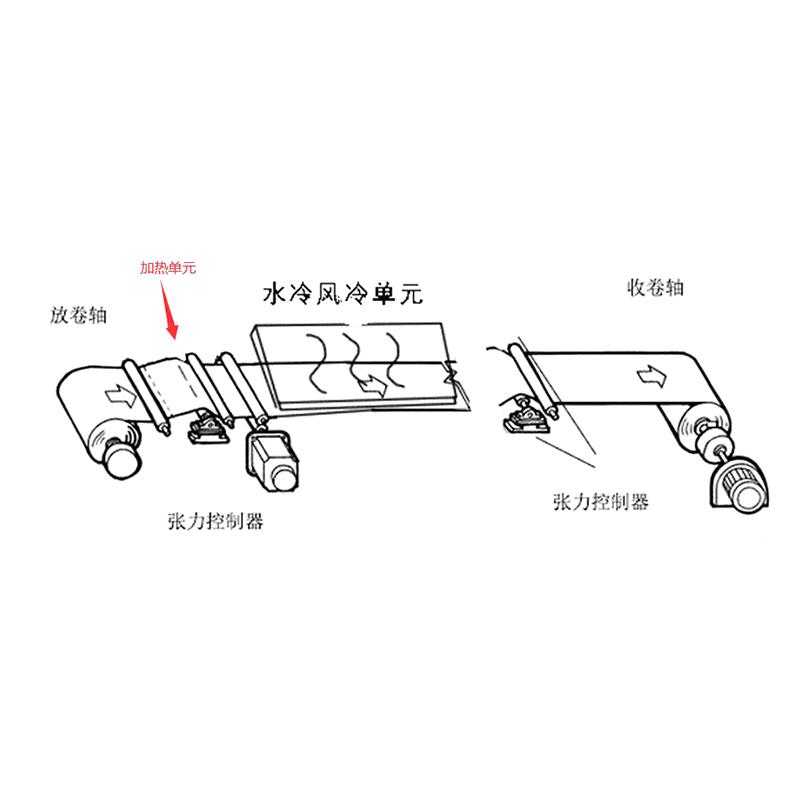

The epoxy coil coating machine has the characteristics of high efficiency, automation and high precision. The coating process mainly includes steps such as substrate transfer, coating, and curing, and involves the coordination and control of a variety of process parameters. During the selection and use of the coating machine, the performance requirements under different working conditions need to be fully considered to ensure the quality and stability of the coating film.

Part 2: Selection method of epoxy coil coating machine

2.1 Basis for selection

When choosing an epoxy coil coater, you first need to clarify the coating materials, specifications, process requirements, etc. according to actual needs, and then consider factors such as production efficiency, equipment stability, and maintenance costs. At the same time, factors such as the manufacturer's reputation, after-sales service, and equipment upgradeability also need to be comprehensively considered.

2.2 Common types and specifications

Epoxy coil coaters can be divided into roller coating type, spray coating type, scraper coating type, etc. according to the coating method. Depending on the size of the production line and process requirements, the specifications of the coating machine also vary. Smaller-scale production lines can choose small coating machines, while large-scale production lines need to consider high-capacity and highly automated equipment.

2.3 Basic parameter selection

During the selection process, you need to pay attention to the basic parameters of the coating machine, such as coating speed, coating width, coating thickness control accuracy, etc. The selection of these parameters should match the characteristics of the coating material to ensure that the quality of the coating film meets the requirements.

Part Three: Adjustment and Control of Coating Film Parameters

3.1 Coating speed

Coating speed is one of the important factors affecting the uniformity and quality of coating films. In practical applications, the choice of coating speed should take into account the balance between production efficiency and coating film quality. Higher coating speed can improve production efficiency, but it can also easily affect the uniformity of the coating film, so appropriate adjustments and controls are required in production practice.

3.2 Coating thickness control

The coating thickness is directly related to the performance of the coating film and therefore requires precise control. Modern coating machines are usually equipped with advanced thickness control systems, which can achieve precise control of coating thickness by automatically adjusting parameters such as roller pressure and spray pressure. In actual operation, operators need to monitor the coating film thickness at any time according to production requirements and make reasonable adjustments to the control system.

3.3 Temperature control

During the coating process of epoxy membrane, temperature has an important impact on the curing and performance of the coating film. Therefore, coating machines are usually equipped with a temperature control system, which can achieve precise control of the coating temperature by adjusting the temperature of heating rollers, ovens and other components. Reasonable coating temperature helps to improve the adhesion and hardness of the coating film.

Part 4: Future development trends of epoxy coil coating machines

4.1 Automation and intelligence

With the development of Industry 4.0, the automation and intelligence level of coating machines will be further improved. Future coating machines will be more intelligent, capable of real-time monitoring of various parameters during the coating process through sensors, and automatic adjustments based on real-time data to improve production efficiency and coating film quality.

4.2 Environmental protection and energy saving

Environmental protection and energy saving are important trends in current industrial production. As a key equipment in the production line, coating machines will also face higher environmental protection and energy saving requirements. Future coating machines will use more environmentally friendly coatings and processes, and at the same time achieve more efficient use of energy by optimizing equipment structures and control systems.

4.3 Intelligent maintenance

Future coating machines will pay more attention to intelligent maintenance. Through remote monitoring and diagnosis systems, equipment faults can be discovered in a timely manner and remote maintenance can be performed. This will greatly reduce equipment downtime and improve the stability and reliability of the production line.

Conclusion

As an indispensable equipment in modern industrial production, epoxy coil coater plays a key role in improving coating film quality, production efficiency and environmental protection performance. Through scientific and reasonable selection and precise coating parameter control, the diverse needs of different industries for epoxy coil coating can be better met.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Application of doctor blade coater in electrode and solid electrolysis preparation

- 3Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 4Systematic understanding of coil isolation film coater

- 5Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 6The principle and application of miniature coil spraying machine

- 7Several Common Experimental Spreader Methods and Their Applications

- 8Application of laboratory coater coating aluminum oxide paste on PET film

- 9Experimental test of performance of epoxy resin film coated on metal iron plate by small coater