Comparison between hot-melt adhesive double-sided coater and hot-melt adhesive coil coater

introduction

In modern industrial production, hot melt adhesive technology has become a widely used method for bonding and coating various materials. In order to improve production efficiency and product quality, different types of hot melt adhesive coating equipment have gradually emerged. Among them, hot melt adhesive double-sided coating machine and hot melt adhesive coil coating machine are two common coating equipment, each with unique characteristics and advantages. This article will conduct a comprehensive comparison of these two coating machines and explore their technical similarities and differences, so that manufacturing companies can make informed decisions based on their needs when choosing coating equipment.

1. Working principle and characteristics of hot melt adhesive double-sided coating machine

Hot melt adhesive double-sided coating machine is a special equipment that is widely used in double-sided coating processes. Its basic working principle is to evenly coat the hot melt adhesive on the substrates on both sides, and then merge the two substrates together through certain process steps to form a composite material with a double-sided coating. This kind of coating machine usually includes main components such as melt glue system, coating system, heating system and pressing system.

In the hot melt adhesive double-sided coating machine, the melt adhesive system is one of the core parts. This system heats the hot melt adhesive to a liquid state and then evenly coats it on the substrate through the coating system. At the same time, the heating system ensures that the hot melt adhesive maintains a suitable liquid temperature to ensure the stability of the coating process. Finally, the lamination system is responsible for tightly combining the substrates on both sides to form a double-sided coating.

The advantage of the hot melt adhesive double-sided coating machine lies in its efficient and uniform coating process. Due to the design of the coating system, it enables precisely controlled double-sided coating, ensuring product consistency and high quality.

2. Working principle and characteristics of hot melt adhesive coil coating machine

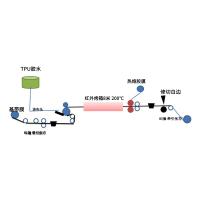

Hot melt adhesive coil coater is another common coating equipment, mainly used to evenly coat hot melt adhesive on coils. Its working principle is relatively simple, and it mainly includes components such as a web conveying system, a coating system, a melting system, and a curing system.

In the hot melt adhesive web coating machine, the web conveying system is responsible for smoothly transporting the web to the coating area. The coating system evenly coats the hot melt adhesive on the surface of the coil to form the required coating layer. The melt adhesive system maintains the appropriate temperature of the hot melt adhesive to ensure that it remains fluid during the coating process. Finally, the curing system solidifies the hot melt adhesive through a certain heating or cooling process to form a strong coating layer.

Hot melt adhesive web coating machines are characterized by their flexibility and wide range of applications. Due to its simple coating process, the equipment is suitable for a variety of roll materials, including paper, film, fabric, etc. At the same time, due to its roll delivery method, it can adapt to rolls of different sizes and lengths, increasing production flexibility.

3. Technical comparative analysis

Coating method:

The hot melt adhesive double-sided coating machine mainly adopts double-sided coating method and is suitable for production processes that require hot melt adhesive to be evenly coated on both sides. The hot melt adhesive coil coating machine is mainly used for single-sided coating of coils, and is more suitable for the coating needs of coil products.

Applicable materials:

Hot melt adhesive double-sided coating machine is mainly used for thicker and harder substrates, such as synthetic materials, composite materials, etc. Hot melt adhesive coil coating machine is more suitable for coating flexible materials such as film and paper.

Productivity:

Since the hot melt adhesive double-sided coating machine adopts double-sided coating, its production efficiency is relatively high and it is suitable for mass production. Due to its single-sided coating, the hot melt adhesive coil coating machine is suitable for small batch or multi-variety production and has greater flexibility.

Device complexity:

The hot melt adhesive double-sided coating machine involves multiple systems such as coating system, heating system, and lamination system, and the equipment is relatively complex. The hot melt adhesive coil coating machine is relatively simple in terms of coating system, melting system and curing system, and is suitable for production scenarios with relatively low equipment requirements.

4 Conclusion

Hot melt adhesive double-sided coating machines and hot melt adhesive coil coating machines respectively play an important role in industrial production with their unique coating methods and scope of application. When selecting coating equipment, manufacturing companies need to weigh various factors based on specific needs and choose the equipment that best suits their production processes.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Application of doctor blade coater in electrode and solid electrolysis preparation

- 3Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 4Systematic understanding of coil isolation film coater

- 5Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 6The principle and application of miniature coil spraying machine

- 7Several Common Experimental Spreader Methods and Their Applications

- 8Application of laboratory coater coating aluminum oxide paste on PET film

- 9Experimental test of performance of epoxy resin film coated on metal iron plate by small coater