Detailed explanation of heating coil coater technology and introduction of heating system

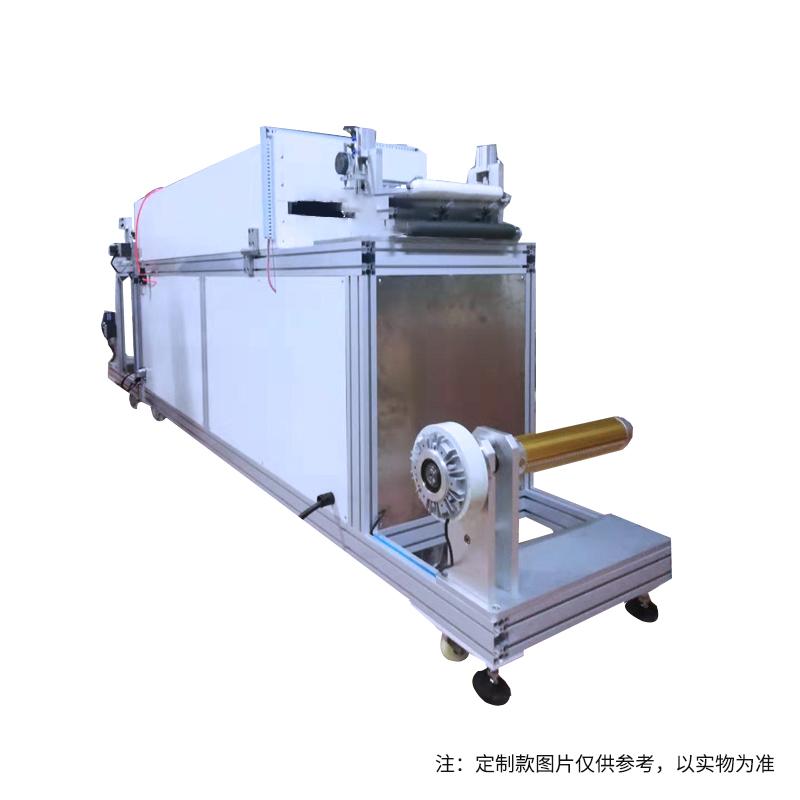

The heated coil coater is a piece of equipment widely used in the fields of printing, packaging and coating. Its unique heating system enables it to adapt to different types of coils and achieve efficient coating. This article will delve into the core technology of the heated coil coater, focusing on the design principles, working methods and maintenance methods of its heating system.

introduction

Heated coil coaters play a key role in modern industry, and their applications span many industries. By introducing a heating system during the coating process, this coating machine can not only increase the temperature of the coil surface and increase the fluidity of the material, but also accelerate the evaporation of the solvent and improve the coating efficiency. This article will comprehensively introduce the technical characteristics of the heated coil coater, focusing on the key design and working principle of its heating system.

Core technical parameters

Heating system design parameters

1.1 Heating method: The heating system of the heating coil coating machine usually adopts radiation heating, convection heating or conduction heating. Different heating methods are suitable for different coil materials and coating requirements.

1.2 Heating elements: Heating elements in the heating system include electric heating tubes, infrared radiators, etc., and their selection is directly related to the heating effect. Efficient heating elements not only increase heating speed but also reduce energy consumption.

1.3 Temperature control: The advanced heated coil coating machine is equipped with a precise temperature control system, which can monitor the surface temperature of the coil in real time and automatically adjust the heating power through a feedback mechanism to ensure temperature stability.

Coating parameters

2.1 Coating speed and width: The coating speed and width of the heated coil coater are still the core technical parameters. Their reasonable settings can ensure the coordination of heating and coating and improve production efficiency.

2.2 Heating area control: During the coating process, different coils may need to be heated in different areas. The advanced coating machine has the function of regional control, which can realize local heating according to the characteristics of the coil and improve the process adaptability.

How the heating system works

Radiant heating

Radiant heating is one of the common heating methods used in heated coil coaters. The radiant energy generated by the electric heating tube or infrared radiator is quickly transferred to the surface of the coil to heat it up. Radiant heating is fast and efficient and is suitable for some temperature-sensitive materials.

Convection heating

Convection heating heats the air to form a convection airflow, and then transfers the heat energy to the surface of the coil. This method is suitable for some coils that require uniform heating and has the advantage of uniform temperature distribution.

conduction heating

Conduction heating conducts heat energy through direct contact, transferring heat energy to the web. This method is suitable for some materials with good conductivity and has the characteristics of high efficiency and energy saving.

Maintenance method

The heating system of the heated coil coater requires regular maintenance to ensure stable operation of the equipment and extend its service life.

Regularly check the heating element: Regularly check the heating element to ensure that it is working properly and avoid a decrease in heating effect due to element damage.

Clean the heating area: The heating area is prone to accumulation of dust and residue. Regular cleaning can prevent these substances from affecting the heating effect.

Temperature control system calibration: Calibrate the temperature control system regularly to ensure its accuracy. Too high or too low temperature may affect the coating effect.

Heating system protection: Heating systems require protective measures to avoid accidents. Install overload protection devices, temperature alarm devices, etc. to improve equipment safety.

in conclusion

The heated coil coating machine has successfully overcome a series of problems in the coating process by introducing an advanced heating system, providing efficient and accurate solutions for printing, packaging and coating industries. This article discusses in detail the core technical parameters, working principles and maintenance methods of the heated coil coating machine, hoping to provide useful technical reference for practitioners in related industries and promote the development of science and technology and the improvement of production efficiency in this field.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Application of doctor blade coater in electrode and solid electrolysis preparation

- 3Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 4Systematic understanding of coil isolation film coater

- 5Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 6The principle and application of miniature coil spraying machine

- 7Several Common Experimental Spreader Methods and Their Applications

- 8Application of laboratory coater coating aluminum oxide paste on PET film

- 9Experimental test of performance of epoxy resin film coated on metal iron plate by small coater