Analysis and application of non-woven hot-melt adhesive coater technology

The non-woven hot melt adhesive coating machine is a key equipment and is widely used in the production process of non-woven products. This article will provide a detailed analysis of the technical principles, structural composition, working process and application fields of non-woven hot melt adhesive coating machines, and discuss its application status and future development trends in the current industry.

introduction

Non-woven fabric is a new type of textile material with excellent air permeability, wear resistance and waterproofness. It is widely used in medical, health, home furnishing, agriculture and other fields. In the manufacturing process of non-woven products, hot melt adhesive coating technology plays an important role. As the key equipment to realize this technology, the non-woven hot melt adhesive coating machine's performance and stability directly affect product quality and production efficiency.

Technical principles

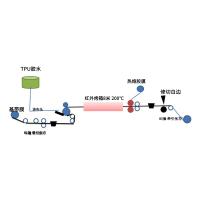

The working principle of the non-woven hot melt adhesive coating machine is mainly to melt the adhesive by heating, and then evenly apply the melted glue on the surface of the non-woven fabric through the coating roller, and finally form an adhesive coating layer. Its core technology lies in the control of molten glue and the uniformity of coating thickness.

Structure and composition

(1) Feeding system: The components that feed the non-woven fabric into the coating area, usually including tension control devices and feeding rollers.

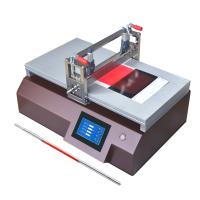

(2) Coating system: It consists of a glue melting box, a coating roller, a pressure roller, etc., and is used to evenly coat the melted glue on the surface of the non-woven fabric.

(3) Heating system: used to heat the adhesive in the melting box to a liquid state, usually using electric heating or steam heating.

(4) Control system: including temperature control system, coating thickness control system, etc., used to achieve precise control of the coating process.

work process

(1) Start the equipment and set parameters: First start the equipment, set the temperature of the melt box and coating roller, and adjust parameters such as coating thickness according to product requirements.

(2) Preheating stage: The melting box begins to heat, heating the solid adhesive to a liquid state and reaching the set working temperature.

(3) Feeding and coating: The non-woven fabric is fed into the coating area through the feeding system. The coating roller evenly coats the melted glue on the surface of the non-woven fabric. At the same time, the pressure roller acts to ensure uniform coating thickness.

(4) Curing and finishing: After the coating is completed, the non-woven fabric enters the curing area, and the glue coating layer is solidified by heating or cooling, and finally passes through the finishing device to ensure that the product surface is smooth.

Application areas

Non-woven hot melt adhesive coating machines are widely used in medical and health, sanitary napkins, diapers, non-woven bags and other fields. In the field of medical and health care, non-woven coating machines can be used to manufacture surgical gowns, masks and other products; in the production of sanitary napkins and diapers, they can be used to fix adhesives on the absorbent core and surface layer; in the production of non-woven bags, they can be used to manufacture Shopping bags, packaging bags and other products.

Conclusion

As a key equipment in the production process of non-woven products, non-woven hot melt adhesive coating machine plays an important role in modern industry. By analyzing its technical principles, structural composition, working process and application fields, this article hopes to better understand the working principle and application status of this equipment, and look forward to its future development trends.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Application of doctor blade coater in electrode and solid electrolysis preparation

- 3Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 4Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 5Several Common Experimental Spreader Methods and Their Applications

- 6Application of laboratory coater coating aluminum oxide paste on PET film

- 7Experimental test of performance of epoxy resin film coated on metal iron plate by small coater

- 8Method and application of experimental coater coating water-based slurry on aluminum foil

- 9Application of wire rod coater in hydrogen battery separator prepative