Application and Technological Innovation of Coater Scratching Hot-melt Adhesive on PET Film

Summary:

This article introduces the application of hot melt adhesive coating machine on PET film. First, the basic characteristics of PET film and hot melt adhesive are introduced, and then the process flow and operating steps of the coating machine for scraping hot melt adhesive on PET film are explained in detail, including equipment selection and debugging, operating precautions, etc. Then the application fields and advantages of hot melt adhesive coating on PET film by coater were discussed, including its wide application in packaging, labels, building materials and other industries. Finally, the development trend of hot melt adhesive coating by coating machines on PET films was prospected, and the future technology and market prospects were pointed out.

Keywords: coating machine, PET film, hot melt adhesive, application, development trend

introduction

A coater is a device used to apply paint or glue on the surface of a substrate. It is widely used in packaging, printing, building materials and other fields. PET film is a commonly used plastic substrate with excellent mechanical properties and chemical stability. It is widely used in packaging, labels, electronic products and other fields. Hot melt adhesive is a commonly used bonding material with the characteristics of fast curing, high strength, and high temperature resistance. It is widely used in textile, packaging, construction and other fields. Combining the coating machine with PET film and hot melt adhesive can achieve coating on the surface of the PET film, giving the PET film more functions and application value. This article will introduce in detail the application of hot melt adhesive coating machine on PET film.

Basic characteristics of PET film and hot melt adhesive

(1) PET film: PET film is a plastic film made of polyethylene terephthalate (PET) as raw material. It has excellent transparency, heat resistance, mechanical strength and chemical stability, and is widely used in packaging, labels, electronic products and other fields.

(2) Hot melt adhesive: Hot melt adhesive is a glue that is solid at room temperature and becomes liquid after heating. It has the characteristics of fast curing, high strength, high temperature resistance, and environmental protection, and is widely used in textile, packaging, construction and other fields.

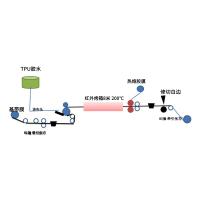

The process flow and operating steps of the coating machine for applying hot melt adhesive on PET film

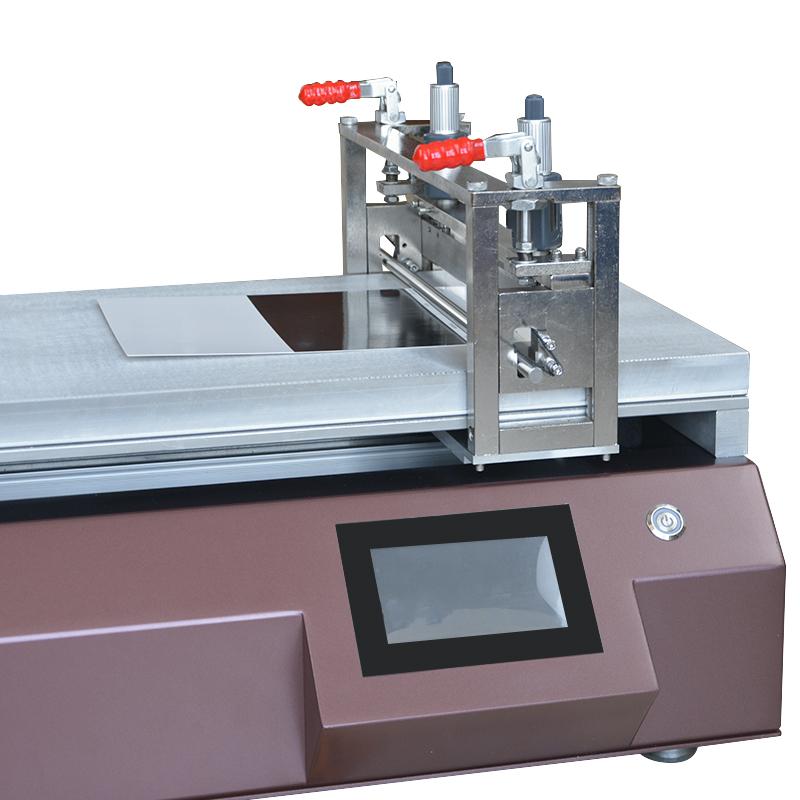

(1) Equipment selection: Select a coating machine suitable for PET film coating. Considering the characteristics of the PET film, a coating machine that can achieve uniform coating should be selected.

(2) Equipment debugging: debug coating machine parameters, including scraping speed, temperature, pressure and other parameters to ensure coating quality and efficiency.

(3) PET film pretreatment: Place the PET film on the coating machine and perform surface treatment, such as cleaning, dust removal, etc.

(4) Hot melt adhesive coating: Start the coater and apply the hot melt adhesive evenly on the surface of the PET film through the scraper head.

(5) Curing treatment: Send the coated PET film to the curing equipment for curing treatment to ensure the curing and adhesion of the hot melt adhesive.

Application fields and advantages of coating machine for applying hot melt adhesive on PET film

(1) Packaging industry: Hot melt adhesive applied by a coating machine can be used for sealing and bonding PET films to improve the sealing and aesthetics of packaging.

(2) Label industry: Hot melt adhesive applied by a coating machine can be used for label backing of PET film to improve the adhesion and durability of the label.

(3) Building materials industry: Hot melt adhesive applied by a coating machine can be used as roof waterproofing material of PET film to improve the waterproof performance and weather resistance of the roof.

The development trend of coater coating hot melt adhesive on PET film

The coating machine has broad application prospects for scraping hot melt adhesive on PET film. With the wide application of PET film in packaging, labeling, construction and other fields, the demand for coating machines to apply hot melt adhesive will continue to increase. In the future, the coating machine's technology for scraping hot melt adhesive will continue to innovate, improve coating speed and coating quality, expand new application areas, and provide more possibilities for the development of PET films.

in conclusion

The application of hot melt adhesive on PET film by a coater is an effective coating process with a wide range of applications and advantages. With the continuous development of PET film and hot melt adhesive, the technology and application of hot melt adhesive coating machine will continue to be improved, providing more possibilities for the application of PET film and promoting the development of related industries.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Application of doctor blade coater in electrode and solid electrolysis preparation

- 3Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 4Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 5Several Common Experimental Spreader Methods and Their Applications

- 6Application of laboratory coater coating aluminum oxide paste on PET film

- 7Experimental test of performance of epoxy resin film coated on metal iron plate by small coater

- 8Method and application of experimental coater coating water-based slurry on aluminum foil

- 9Application of wire rod coater in hydrogen battery separator prepative