Analysis of extrusion hot-melt adhesive coater technology and comparative study of coil hot-melt adhesive coater

introduction

Hot melt adhesive coating technology plays an important role in industrial production, and its application range covers textile, packaging, construction and other fields. In hot melt adhesive coating technology, extrusion hot melt adhesive coating machine and coil hot melt adhesive coating machine are two common processes. This article aims to conduct an in-depth discussion and comparison of these two technologies, analyze their advantages and disadvantages, and their applicability in different fields.

Analysis on Extrusion Hot Melt Adhesive Coating Machine Technology

The extrusion hot melt adhesive coating machine is a kind of equipment commonly used for coating hot melt adhesive. Its working principle is to turn the hot melt adhesive into a liquid state by heating, pressurizing, etc., and then extruding the hot melt adhesive through the extrusion head. Glue is applied to the surface of the material to be bonded.

working principle

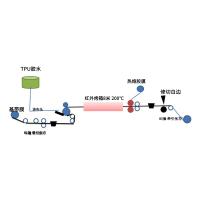

The extrusion hot melt adhesive coating machine is mainly composed of glue supply system, heating system, extrusion system, coating system and control system. First, solid hot melt adhesive particles are put into the glue supply system. After being heated by the heating system, the hot melt glue gradually melts into a liquid state. Then, the melted hot melt adhesive is fed into the coating system through the extrusion system, and finally the hot melt adhesive is evenly coated on the material surface through the coating system.

advantage

Efficiency: The extrusion hot melt adhesive coating machine can achieve continuous and high-speed coating of hot melt adhesive with high production efficiency.

Uniform coating: Due to the extrusion system, the hot melt adhesive can be evenly extruded and coated on the material surface, ensuring the stability of the coating quality.

Wide applicability: suitable for coating materials of various shapes, such as film, paper, cloth, etc.

shortcoming

High equipment cost: The equipment cost of the extrusion hot melt adhesive coating machine is relatively high and requires a large investment.

Difficulty in maintenance: The equipment involves multiple systems, and maintenance and upkeep are relatively complex, requiring professional and technical personnel to perform maintenance.

Comparative study on coil hot melt adhesive coating machines

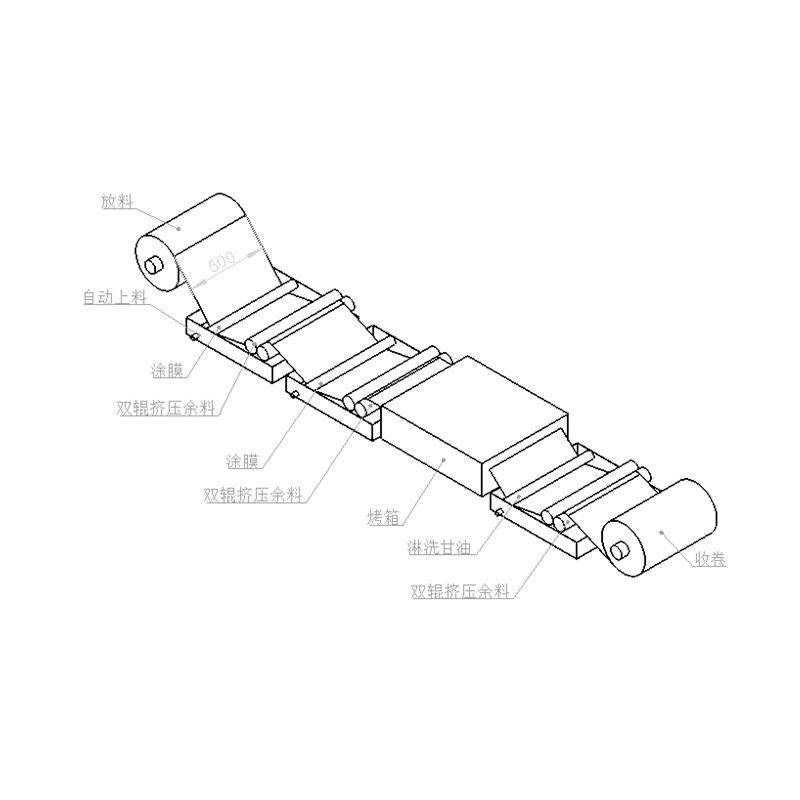

Compared with the extrusion hot melt adhesive coating machine, the coil hot melt adhesive coating machine has different working principles and application scenarios. The coil hot melt adhesive coating machine is mainly used to coat hot melt adhesive on the surface of coil materials, such as paper, plastic film, etc.

working principle

The coil hot melt adhesive coating machine usually consists of a coating roller, a melt tank, a hot melt adhesive pump and other parts. First, put the solid hot melt adhesive particles into the melt tank and melt them into a liquid state through the heating system. Then, the melted hot melt adhesive is sent to the coating roller through the hot melt adhesive pump, and then the hot melt adhesive is evenly coated on the surface of the coiled material through the coating roller.

advantage

Easy to operate: Compared with extrusion hot melt adhesive coating machines, coil hot melt adhesive coating machines are relatively simple to operate and easy to use.

Wide applicability: suitable for coating roll materials, such as paper, plastic film, etc.

Relatively low equipment costs: Compared with extrusion hot melt adhesive coating machines, equipment costs are low.

shortcoming

Low production efficiency: Due to the limitations of its working principle, the production efficiency of the coil hot melt adhesive coating machine is low.

Unstable coating quality: Due to the limitations of coating rollers and other components, the coating quality may not be as stable as an extrusion hot melt adhesive coating machine.

Conclusion and Outlook

Extrusion hot melt adhesive coating machines and coil hot melt adhesive coating machines are both important hot melt adhesive coating technologies, each with its own advantages and disadvantages. When choosing which technology to use, a comprehensive consideration needs to be based on specific production needs and product characteristics. In the future, with the continuous development of science and technology, hot melt adhesive coating technology will continue to innovate and improve, providing more efficient and stable solutions for production in various industries.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Application of doctor blade coater in electrode and solid electrolysis preparation

- 3Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 4Systematic understanding of coil isolation film coater

- 5Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 6The principle and application of miniature coil spraying machine

- 7Several Common Experimental Spreader Methods and Their Applications

- 8Application of laboratory coater coating aluminum oxide paste on PET film

- 9Experimental test of performance of epoxy resin film coated on metal iron plate by small coater