Comparison of advantages and disadvantages of preparing large area perovskite films by doctor blade Spreader method and spin coating method

introduction

Perovskite materials have attracted much attention due to their wide application in optoelectronic devices, and the preparation of high-quality large-area thin films is the key to realizing their applications. Blade coating and spin coating are two commonly used methods to prepare large-area perovskite films. Through a comparative study of these two methods, this article aims to evaluate their advantages and disadvantages in preparing large-area perovskite films. The methods and conclusions of this article are extracted from the experimental results of the study "Preparation of large-area high-efficiency perovskite light-emitting diodes through low-temperature drawdown blade coating" to allow users to understand the advantages and disadvantages of the two coating methods.

method

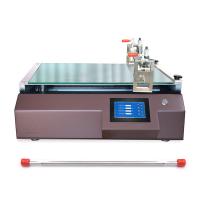

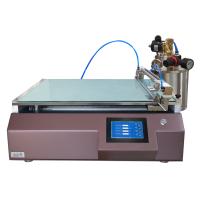

In the study "Preparation of large-area high-efficiency perovskite light-emitting diodes by low-temperature blade coating" , a large-area calcium oxide with an area of ââ6 Ã 9 cm2 was prepared using a 0.04 M precursor solution and a blade coating method and a solvent exchange method respectively. titanite films and compared their preparation processes and film properties. The macroscopic and microscopic morphological uniformity of the films was examined by thickness analyzer and atomic force microscopy, and the optoelectronic properties of the films were measured.

result

By comparison, the film prepared by the blade coating method is very uniform, with a roughness of about 1 nm, while the film prepared by the spin coating method reaches 4-5 nm in the center area and >10 nm in the edge area. The films prepared by blade coating are very uniform in photoluminescence (PL) emission, while the films prepared by spin coating have weaker PL emission in the edge region. In addition, films prepared by blade coating have higher PL quantum yield (PLQY), longer average carrier lifetime (T average), and better uniformity.

discuss

The blade coating method has obvious advantages over the spin coating method in preparing large-area perovskite films. The blade coating method not only achieves higher uniformity and lower roughness, but also saves a large amount of precursor solution. In addition, films prepared by the blade coating method perform better in terms of optoelectronic properties, with higher PLQY and longer average carrier lifetime, which are crucial to the performance of optoelectronic devices. Therefore, the drawdown blade coating method is a reliable and efficient method for preparing large-area perovskite films and has broad application prospects.

Note: The above comparison is for perovskite LED film preparation and may not be suitable for other applications.

- 1Kinetic control of silicon carbon cathode Spreader drying: key technology to solve crazing and powder drop

- 2Advantages of drawdown blade method in preparation of perovskite solar cells

- 3Application of doctor blade coater in electrode and solid electrolysis preparation

- 4Application of Spin Coater in preparation of Bi1.5MgNb1.5O7 film

- 5Automatic Film Applicator and spin coating spin coater: Key technologies and applications in industrial production

- 6Experimental Study on Spreader Lithium Ion Separator on PP Material for Doctor blade coater

- 7Two Methods of Preparative Anti-oxidation polymer Encasement Film

- 8Perovskite solar cell preparatory method using solvent immersion resistant applicator

- 9Technical Principle and Advantage of Preparation of Oxidation Wax by Doctor blade Spreader