Determination of leather colour fastness by swirl/spin friction Tester

Leather products occupy an important place in daily life and industry, however, in order to ensure their quality and durability, various tests need to be carried out to evaluate their performance. Among them, color fastness test is one of the important evaluation indicators. This article will introduce a common method in leather color fastness: the rotating rubbing color fastness test. This test is designed to evaluate the color fastness of leather products to rubbing to determine whether the color will fade or transfer during use.

principle

The G B/T 42949-2023 standard has come into effect on April 1, 2024. This article attempts to interpret the standard and combines industry experience to explain how to use a rotating friction resistance testing machine to detect the color fastness of leather, including various types of leather and Leather products, used to determine the color fastness to rotational rubbing.

The principle is to use a felt to apply rotational friction on the surface of the sample under a specified pressure, and then use a gray sample card to evaluate the degree of discoloration of the sample and the degree of staining of the felt to evaluate the color fastness.

Instruments and Materials

Rotary friction resistance testing machine, circular combed felt, gray sample card for staining evaluation and gray sample card for discoloration evaluation, filter paper, deionized water, artificial sweat, sample holder

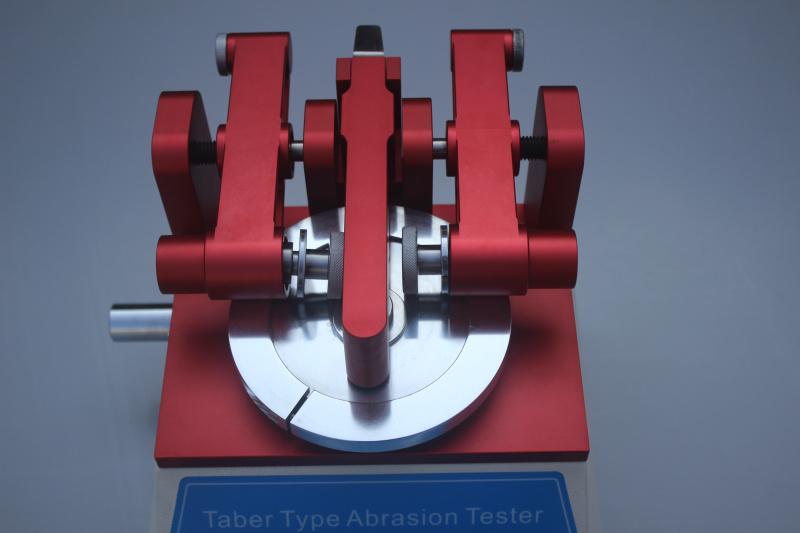

The rotary friction Tester is a key equipment used to evaluate the color fastness to rotational rubbing of leather and other materials. Its working principle is to rotate the felt fixed on the rotating shaft under a prescribed pressure, so that it contacts the surface of the sample and exerts friction, simulating the friction that leather products may encounter in daily use. During the test, the sample undergoes continuous rotational friction, and the number and intensity of friction are usually specified by the test standard. By evaluating the degree of discoloration of the sample and the degree of staining of the felt, the color fastness of leather products under friction can be accurately evaluated, providing an important reference for product quality control and improvement.

Experimental steps

1. Preparation and adjustment of specimens

Specimen preparation - ensure that the surface of the specimen is smooth, without stitching, perforation, drilling or weaving.

Specimen preparation is a key step in rotational friction resistance testing, and its purpose is to ensure the accuracy and reliability of the test. First, it is necessary to ensure that the specimen surface is flat, as irregular or uneven surfaces may affect the accuracy of the test results. Secondly, the specimen should avoid processes such as sutures, perforations, holes, or weaving, as these may cause unevenness and abnormalities during the friction process. These poor processes may affect the contact between the sample and the felt in the test, thereby affecting the color change and staining during the friction process. Therefore, during the sample preparation process, special attention must be paid to details and the surface of the sample must be smooth and defect-free to ensure the accuracy and reliability of the test results.

Adjustment of specimens and feltsâAdjust specimens and felts according to regulations, and the test should be conducted in a standard atmosphere under the same conditions.

2. Test steps

(1) Dry friction test

Fix the sample on the test platform, load the load-bearing block to make the test head pressure reach the specified value, and then rub it until the specified number of times.

The dry rubbing test is a method for evaluating the color fastness of materials, in which the sample surface and the rubbing felt are both dry. The sample is fixed on the test platform, loaded with a weight-bearing block to apply the specified pressure, and then rotated and rubbed with dry felt until the specified number of frictions is reached. This test simulates the use of the material in a dry environment and is designed to evaluate its color fastness performance under dry conditions.

(2) Wet friction test

Fix the wet felt on the rotating shaft of the testing machine and repeat the dry friction test steps.

The wet rubbing test is a method to evaluate the color fastness of materials, in which the surface of the sample is in a dry state, and the rubbing felt is soaked in deionized water in advance to make it moist but not dripping. The sample is fixed on the test platform, loaded with a weight-bearing block to apply the specified pressure, and then rotated and rubbed with the wet felt until the specified number of frictions is reached. This test simulates the use of materials in a humid environment and examines their color fastness performance under humid conditions.

(3) Sweat friction test

Fix the felt soaked in artificial sweat on the rotating shaft of the testing machine and repeat the dry friction test steps.

The sweat friction test is a method to evaluate the color fastness of materials, in which the surface of the sample is in a dry state, and the friction felt is soaked in artificial sweat to make it moist. The sample is fixed on the test platform, loaded with a weight-bearing block to apply the specified pressure, and then rotated and rubbed with a felt soaked in artificial sweat until the specified number of frictions is reached. This test simulates the use of materials under contact with human sweat and examines their color fastness performance in a sweat environment.

3. Result evaluation

After the test, use the gray sample card to evaluate the staining grade of the felt and the discoloration grade of the leather sample, and record other visible changes on the surface of the sample. The evaluation results should meet the specified standards and be evaluated under D65 light source conditions.

The difference in assessment results between different Testers should not exceed half a level to ensure the accuracy and consistency of the assessment results.

Through the rotating rubbing color fastness test, the color fastness of leather products under rubbing can be evaluated, providing an important reference for product quality control and improvement. However, when conducting tests, it is necessary to strictly follow the standards and pay attention to error control during the assessment process to ensure the accuracy and reliability of the assessment results.

-

-

-

-

-

FARI FR-1907 TABER Abrasion Tester$ 1559.00

-

-

-

-