Test of film weathering resistance with HNNJIK instrument

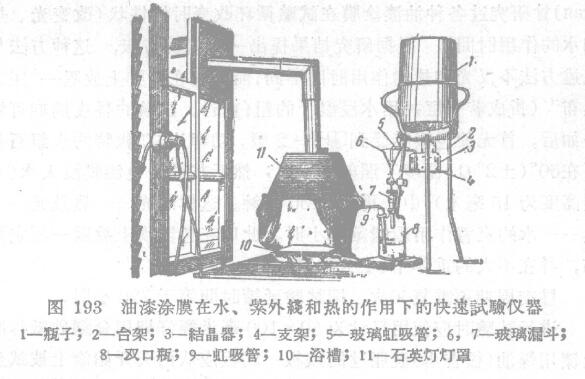

As early as 1933, we proposed a simple device for quick test of paint film by using the alternating action of water, ultraviolet rays, and heat (Fig. 193).

This apparatus is a glass bottle 1 with a capacity of 10 liters placed upside down on a stand 2 . The water surface poured into the glass crystallizer 3 is in contact with the bottleneck. The crystallizer is placed on the lower pillar 4 of the stand. The crystallizer is connected with a glass funnel 6 by means of a siphon tube 5, and the latter communicates with a two-necked bottle 8 through another funnel 7 with a capillary tube at the bottom.

The two-necked bottle is connected with the porcelain bath 10 placed under the mercury quartz lamp through the other mouth with the siphon 9 . Mercury quartz lamp is wrapped in. Lampshade 11 li. There are holes on one side of the bath. A metal tube is welded to the hole, and the tube passes through another hole pierced by cobalt on the table where the whole set of equipment is installed. A rubber tube connects the metal tube to a collector placed on the floor (not visible in the picture).

Before the test, the bottle should be filled with water and the mouth of the bottle should be covered with a piece of filter paper; after that, the bottle should be turned upside down so that the neck of the bottle is immersed in an 8/4 water-filled container placed on the bench, and then the filter paper should be removed. The water in the bottle automatically fills the finisher with the flow of water. Use the cock of the upper funnel to control the water flow, and the two-necked bottle can be filled at any time. The water flow can also be controlled by using the central part on the rubber tube going out from the bath. The capacity of the two-necked bottle should be equal to half of the capacity of the bathtub.

The painted test panel is placed on the bottom of the bath well and the test panel is subjected to water and ultraviolet light successively. In addition, the test panel is also subjected to the heat (approximately 50°C) emitted by the mercury-quartz lamp. The following introduces an instrument usage procedure that has been tested by us and has obtained satisfactory results. The test panel coated with the tested color paint must be subjected to the light effect of 15 points of gold. During this time, the two-necked bottle was gradually filled with water, and the water automatically flowed into the bath from the siphon and remained in the bath for 15 minutes. During this time, water, heat and light act on the tested coating film simultaneously. After 15 minutes of gold, the water gradually flows into the collector through the metal pipe. The wet test panels left in the bath continue to be exposed to light and heat for 30 minutes, and dry during this time. (Associated instrument: Drying Time Meter) The whole cycle then repeats itself. (Related instruments: constant temperature Water Tank)

The test duration is relatively long. For example, the test of oil-based resin paint film without pigment should be carried out continuously for 50 to 70 days in the case of one shift operation; if it is a paint film with high weather resistance, the test duration will be longer .

- 1Analysis of epoxy weathering resistance and detection method

- 2What is weathering resistance?

- 3Study on the Composition and Function of Waterborne Wood Coatings

唐本辉 - 《华南理工大学化学与化工学院》

- 4Light resistance and weather resistance of pigments

吕仕铭 杜长森 周华 - 《《涂料用颜料与填料》》

- 5Coating weathering resistance test

- 6What are the Eletroplating protection performance tests?

- 7How to Prepare High Solids Polyester Resin?

- 8Five Characteristics of Pigment Determine Coating Quality

- 9Factors affecting the weathering performance of coating powder

陈旭峰;叶凡 - 《现代涂料与涂装》