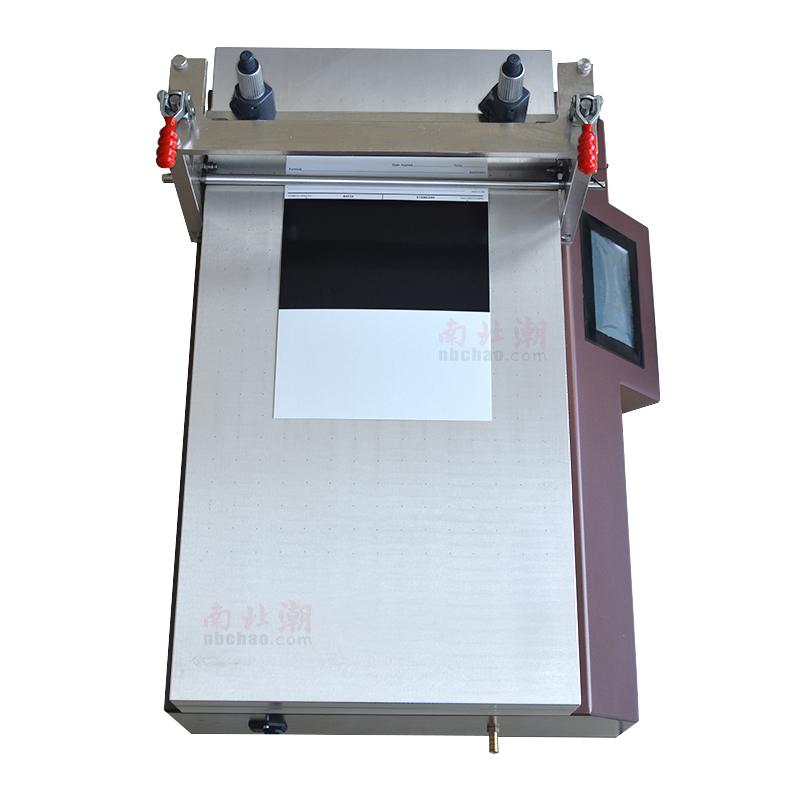

PCB Film Applicator Technology Principle and Application Selection

Summary:

PCB board coating machine is a key equipment used in the printed circuit board (PCB) manufacturing process. It plays an important role in coating the protective layer in PCB manufacturing. This article will deeply discuss the working principle, application scenarios and selection requirements of PCB board coating machines, aiming to provide reference and guidance for researchers and engineers in related fields.

1. Working principle

The PCB board coating machine mainly uses process steps such as coating, curing and cleaning. Its working principle can be summarized as follows:

1.1 Coating

After surface pretreatment, the PCB board is placed on the coating machine. The coating machine sprays or rolls the coating evenly on the surface of the PCB board to form a protective coating. The coating process needs to ensure uniform coating thickness, no bubbles, no scratches, etc.

1.2 Curing

The coated PCB board undergoes baking or ultraviolet curing and other process steps to solidify the coating and firmly bond with the surface of the PCB board to improve the durability and adhesion of the coating.

1.3 Cleaning

The cured PCB board needs to go through a cleaning process to remove impurities such as dirt and residual paint that may remain on the board surface to ensure the cleanliness and coating quality of the PCB board surface.

2. Application scenarios

PCB board coating machines are widely used in the field of electronic manufacturing, mainly including but not limited to the following aspects:

2.1 PCB manufacturing

PCB board coating machines play a key role in the PCB manufacturing process. They are used to apply protective coatings, improve the corrosion resistance, wear resistance and electrical properties of the PCB board, and protect the surface circuits of the PCB board.

2.2 LED lamp manufacturing

During the manufacturing process of LED lamps, it is usually necessary to coat the surface of the lamp with a protective layer to improve its weather resistance and anti-aging capabilities. The PCB board coating machine can achieve fast and even coating on the surface of LED lamps.

2.3 Manufacturing of other electronic components

In addition to PCB and LED lamps, PCB board coating machines are also widely used in the manufacturing process of other electronic components, such as capacitors, resistors, etc. Improve the stability and reliability of electronic components by applying protective coatings.

3. Selection requirements

When choosing a PCB board coating machine, you need to consider the following key factors:

3.1 Coating requirements

Determine the thickness, adhesion, corrosion resistance and other requirements of the coating according to actual application needs, and select the appropriate model and specifications of the coating machine.

3.2 Production efficiency

Consider factors such as the coating speed and production efficiency of the film coating machine to meet production needs and improve production efficiency.

3.3 Equipment stability

Choose brands and models with good stability and reliability to reduce failure rates and maintenance costs and ensure the continuity and stability of the production process.

3.4 Cost considerations

Comprehensive consideration of equipment price, operating costs and other factors, select a cost-effective coating machine model to maximize economic benefits.

4 Conclusion

As an important equipment in the field of electronic manufacturing, PCB board coating machine provides efficient and accurate solutions for surface coating of PCB boards and other electronic components. Through an in-depth understanding of its working principles and application scenarios, and selection based on actual needs, we can provide effective support for research and production in related fields and promote the continuous progress and application of electronic manufacturing technology. It is hoped that this article can provide some reference and guidance for researchers and engineers in related fields, and promote the development and application of PCB board coating technology.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Film Applicator in PEM Research and Preparation

- 8Application of Film Applicator in PVDF-HFP Material Research

- 9Application of Film Applicator in Cosmetic Base Body