Application and Technical Principle of Laboratory Film Applicator in Fiber Membrane prepative

Summary:

Fiber membranes are widely used in biomedicine, environmental protection, energy and other fields, and coating technology plays a vital role in their preparation process. This article will introduce the application of laboratory film coating machines in the preparation of fiber membranes, focusing on exploring the technical principles, including the selection of coating materials, the working principle of the film coating machine, and the optimization of the preparation process. Through an in-depth understanding of the laboratory film coating machine, the actual operation of fiber membrane preparation can be better guided and the quality and performance of the fiber membrane can be improved.

introduction

As an important functional material, fiber membrane is widely used in various fields. For example, fiber membranes can be used in drug delivery, tissue engineering and medical dressings in the medical field; in the field of environmental protection, they can be used for water treatment and pollutant separation; in the energy field, they can be used in batteries and supercapacitors. The performance of fiber membranes often depends on its preparation process, and coating technology is one of the key links in the preparation of fiber membranes.

Basic principles of laboratory coating machines

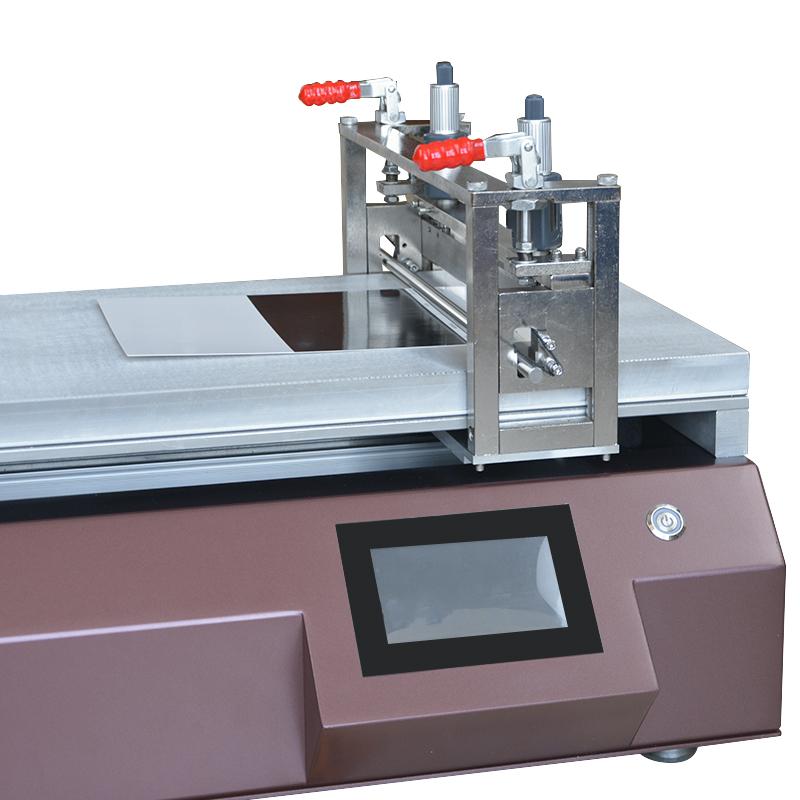

The laboratory Film Applicator is a device used to evenly coat a thin film on the surface of a substrate. Its working principle is based on the rheological properties and mechanical movement of the coating material. Film coating machines usually include coating heads, substrate transmission systems, coating control systems and other parts. The coating head makes the coating material evenly cover the surface of the substrate by controlling parameters such as nozzle spacing, coating speed and coating pressure.

Coating material selection

The choice of coating material is critical to the performance and application of fiber membranes. Commonly used coating materials include polymers, nanomaterials, functional additives, etc. Different coating materials have different properties and can be used to regulate the air permeability, mechanical strength, chemical stability, etc. of fiber membranes.

Application of laboratory film coating machine in fiber membrane preparation

Laboratory film coating machines have important application prospects in fiber membrane preparation. By controlling coating head parameters and coating material properties, fiber membranes with excellent properties can be prepared. For example, a laboratory coating machine can be used to coat a layer of polymer film on the surface of fiber materials to improve the mechanical strength and wear resistance of the fiber membrane; a layer of functional nanomaterials can also be coated on the surface of the fiber membrane to achieve fiber Antibacterial, anti-pollution and other functions of the membrane.

Optimize the preparation process

In order to obtain fiber membranes with excellent properties, the preparation process needs to be optimized. The laboratory coating machine can optimize the microstructure and surface morphology of the fiber membrane by adjusting parameters such as coating speed, coating pressure, and coating temperature. In addition, technical means such as multi-layer coating and alternating coating can also be used to further improve the performance of the fiber membrane.

Conclusion and Outlook

Laboratory coating machines play an important role in fiber membrane preparation. By optimizing the coating process and coating material selection, fiber membranes with excellent performance can be prepared. In the future, with the continuous development of coating technology and the continuous improvement of laboratory coating machines, it is believed that fiber membrane preparation technology will usher in broader development prospects and provide more reliable material support for applications in various fields.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Laboratory Automatic Film Applicator in Coating Battery Slurry on Copper Foil and Aluminum Foil

- 8Application of Film Applicator in PEM Research and Preparation

- 9Application of Film Applicator in PVDF-HFP Material Research