Polyethylene (PE) film laminating machine technology: principles, applications and selection

Polyethylene coating laminating machine is an important plastic processing equipment and is widely used in food packaging, medical equipment, building materials and other fields. This article will introduce the working principle of polyethylene coating film laminating machine, discuss its application in different industries, and provide selection suggestions, with a view to providing reference for related industries.

I. Introduction

Polyethylene coating laminating machine is a device that combines different materials to form a multi-layer composite film. It improves the performance and functionality of products by laminating plastic materials such as polyethylene with other substrates such as paper, aluminum foil, etc. This article will conduct an in-depth discussion of polyethylene coating laminating machines from three aspects: technical principles, application fields and selection guides.

2. Technical principles

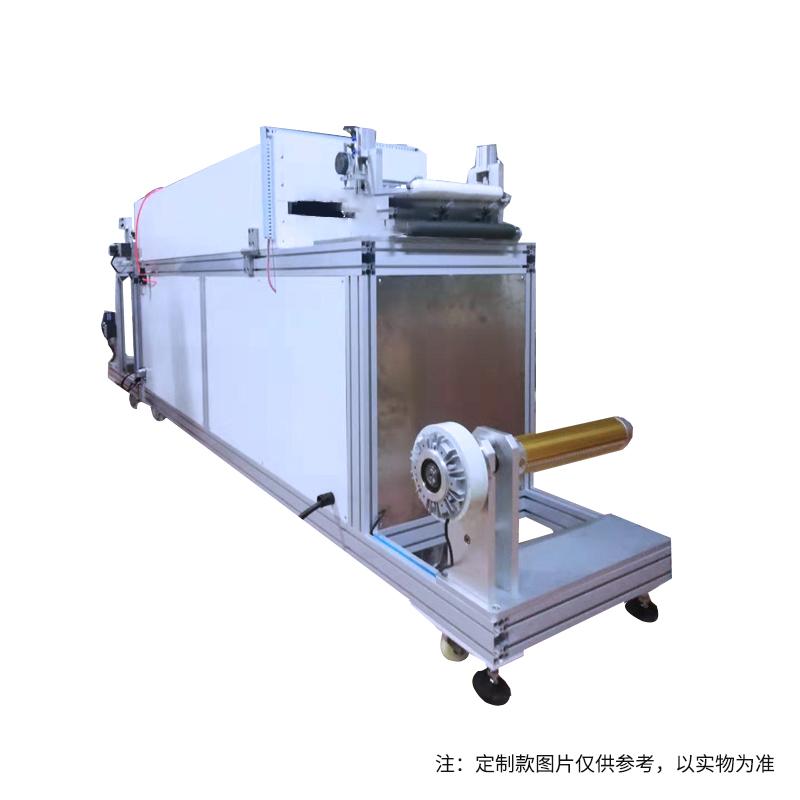

Composition of polyethylene coating film laminating machine The polyethylene coating film laminating machine mainly consists of a winding device, a coating system, a drying system, a laminating device, a tensioning system and a winding device. Among them, the coating system is the core component, which is used to evenly coat molten plastic such as polyethylene on the surface of the substrate.

The working principle of the polyethylene coating laminating machine is to use the coating system to evenly coat the molten polyethylene plastic on the surface of the base material, then solidify it through the drying system, and finally compound the base material and the polyethylene layer through the compounding device. together to form a composite film. The entire process requires precise control of parameters such as temperature, pressure, and speed to ensure the quality of the composite membrane.

3. Application fields

Polyethylene coating laminating machines are widely used in the food packaging industry, such as making food bags, cling film, beverage packaging, etc. It has excellent barrier and sealing properties and can effectively protect the freshness and quality of food. In the field of medical devices, polyethylene coating lamination machines can be used to make medical bags, infusion bags and other products. Due to its non-toxic, odorless and corrosion-resistant properties, it can ensure the safety and hygiene of medical devices. Polyethylene coating laminating machines also have important applications in the field of building materials, such as making waterproofing membranes, thermal insulation materials, etc. It has excellent weather resistance and durability, which can improve the service life and performance of building materials.

4. Selection Guide

Production capacity: When selecting a polyethylene coating laminating machine, you need to select it based on the expected production capacity, including laminating speed, laminating width and other parameters.

Technical performance : Technical performance indicators such as the stability of the coating system, the efficiency of the drying system, and the accuracy of the composite device should be considered to ensure that the equipment can meet production needs.

Equipment quality : Choose equipment brands with good quality and reliability to ensure long-term stable operation of the equipment and reduce failure rates and maintenance costs.

Post-service : Consider the after-sales service capabilities and technical support level of the equipment manufacturer to solve problems in equipment operation in a timely manner and ensure that production is not affected.

5. Conclusion

As an important plastic processing equipment, polyethylene coating laminating machine is widely used in food packaging, medical equipment, building materials and other fields. Choosing a suitable polyethylene coating laminating machine is of great significance to improving product quality and reducing production costs. It is hoped that this article can provide reference for related industries and promote the further development and application of polyethylene coating laminating machine technology.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Film Applicator in PEM Research and Preparation

- 8Application of Film Applicator in PVDF-HFP Material Research

- 9Application of Film Applicator in Cosmetic Base Body