Pharmaceutical Film Applicator Technology Analysis: Key Equipment for Drug Coating

As one of the important equipment in the pharmaceutical industry, the pharmaceutical coating machine plays a key role in drug coating. This article will delve into the working principle, classification, key parameters, operation process and application of pharmaceutical film coating machine in pharmaceutical process, aiming to help readers better understand and apply the technology to improve the quality and production efficiency of drug coating.

In the pharmaceutical industry, drug coating is an important process that not only protects the drug, improves the stability and tolerability of the drug, but also adjusts the release rate of the drug and reduces the irritation. As a key equipment to achieve drug coating, the pharmaceutical coating machine plays an irreplaceable role in the pharmaceutical industry. This article will deeply discuss the technical principles, key parameters, operation procedures and applications of pharmaceutical film coating machines in the pharmaceutical process, in order to provide reference and guidance for practitioners in the pharmaceutical industry.

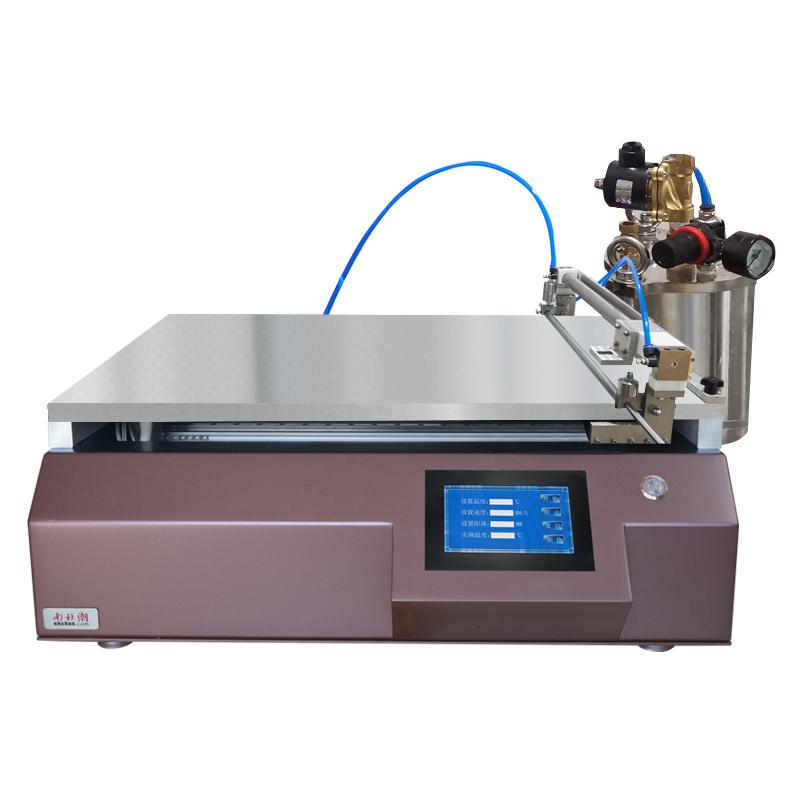

The working principle of the pharmaceutical film coating machine

A pharmaceutical Film Applicator is a device used to administer tablets or granules to cover a layer of film, and its working principle is:The tablets or granules are fed into the coating area of the coater through the feeding device.In the coated area, the tablets or granules are evenly covered with a thin film. The material of the coating film is usually a polymer solution or emulsion, which can be selected according to the characteristics and requirements of the drug, such as HPMC, ethylcellulose, etc.Once the coating is complete, the tablets or granules need to be dried and cured to allow the coating material to form a strong coating. This step is usually carried out by feeding into an oven or drying chamber, where temperature and humidity are controlled to ensure the quality and stability of the film.Finally, the prepared drug coating needs to undergo quality control, including checking the thickness, uniformity, gloss and other indicators of the coating to ensure that it meets the drug registration requirements and pharmaceutical standards.

Classification of pharmaceutical film coating machines

According to the way and principle of film coating, pharmaceutical film coating machines can be divided into the following main types:

3.1 Drum Coating Machine: The film is evenly coated with tablets or particles by rotating the drum.

3.2 Spray Film Applicator: spray the drug solution or emulsion on the tablets or particles through the sprayer to form a film.

3.3 Vacuum coating machine: the use of drying and curing in vacuum to make the drug coating more uniform and stable.

3.4 Air suspension coating machine: The drug particles are suspended in the air through air flow, and then the coating solution is sprayed to form a coating.

Key parameters

The key parameters of the pharmaceutical film coating machine include but are not limited to the following aspects:

4.1 Coating speed: an important parameter that affects the uniformity and production efficiency of the coating film.

4.2 Temperature control: affect the fluidity and curing speed of the coating solution or emulsion.

4.3 Coating film thickness control: directly affects the final thickness and performance of the tablet or granule coating.

4.4 Humidity control: affect the stability and coating effect of the solution or emulsion in the coating process.

apply

Pharmaceutical film coating machines are widely used in various fields in the pharmaceutical industry, including but not limited to the following:

Controlled-release tablet preparation:It is used to regulate the drug release rate and reduce the preparation of controlled-release tablets to reduce drug irritation.

Preparation of coated tablets:It is used to improve the stability of drugs, mask the taste and color of drugs, and the preparation of coated tablets.

Preparation of sustained-release tablets:It is used to prolong the action time of the drug and maintain the blood concentration of the drug in the preparation of sustained-release tablets.

conclusion

As an important equipment in the pharmaceutical industry, the pharmaceutical coating machine has a direct impact on the preparation quality and production efficiency of drug coating. This article has an in-depth discussion on the working principle, classification, key parameters, operation process and application of the pharmaceutical coating machine, aiming to provide reference and guidance for practitioners in the pharmaceutical industry. With the continuous progress of pharmaceutical technology, the pharmaceutical film coating machine will further improve its performance and function, and provide more reliable technical support for the development and production of drug coating.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Film Applicator in PEM Research and Preparation

- 8Application of Film Applicator in PVDF-HFP Material Research

- 9Application of Film Applicator in Cosmetic Base Body