Film Applicators in Resin Moulding

Photosensitive resin is an important material, which has a wide range of applications in printing, lithography, 3D printing and other fields. As one of the key equipment for coating photosensitive resin, the coating machine plays an important role in the preparation and processing of photosensitive resin. This article will deeply discuss the application technology of film coating machine in photosensitive resin, including working principle, operation process, key parameters and application cases in different fields, in order to provide reference and guidance for researchers in the field of photosensitive resins.

introduction

Photosensitive resin is a kind of polymer material with photosensitive properties, which is widely used in printing, lithography, optical devices, microelectronic devices and other fields. Coating is a key part of the preparation and processing of photosensitive resin, and the coating machine, as one of the key equipment to achieve coating, plays an important role in the application of photosensitive resin. In this paper, we will discuss in depth the application technology of film coating machine in photosensitive resin, in order to provide reference and guidance for researchers in related fields.

The working principle of the Film Applicator in the preparation of photosensitive resins

First of all, photosensitive resin is supplied to the coating system of the coating machine as a coating material. Film applicators are typically equipped with applicator heads, which are designed to evenly coat the photosensitive resin on the surface of the substrate. This process is similar to the inking process in printing, but the coater is designed and controlled more precisely to ensure uniformity and precision of the coating.

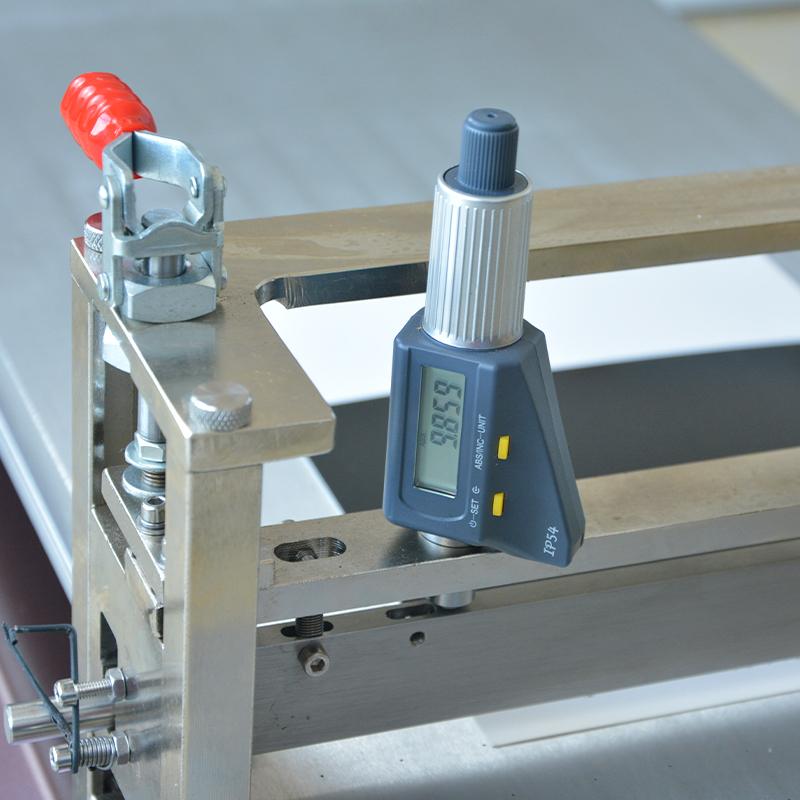

Secondly, the coating head evenly coats the photosensitive resin on the surface of the substrate. The coating head usually consists of a coating tank or coating roller, which is designed so that the photosensitive resin is evenly distributed on the surface of the substrate to form a thin film. The key to this step is to control the parameters of the coating head, including coating speed, coating thickness, coating pressure, etc., to ensure the uniformity and consistency of the coating.

Next, the coated photosensitive resin needs to be dried and cured to form a strong film on the surface of the substrate. This step is usually achieved by feeding into an oven or drying chamber to control the temperature and time of drying to ensure the quality and stability of the photopolymer film.

Finally, the prepared photosensitive resin film needs to be inspected for quality, including checking the coating thickness, uniformity, gloss and other indicators. These tests ensure that the quality of the photosensitive resin film meets the preparation requirements and application requirements.

Examples of applications of Film Applicators in different fields

The application of film coating machine in the field of photosensitive resin covers a variety of fields, including but not limited to the following aspects:

Lithography technology: Coating machines play an important role in the lithography process in semiconductor manufacturing and are used to coat photoresists.

3D printing: The Film Applicator can be used to coat light-sensitive photoresin during the 3D printing process to achieve high-precision printing results.

Printing industry: In the printing industry, Film Applicators can be used to coat photosensitive resins and prepare light-sensitive printing plates.

conclusion

Through the in-depth discussion of the working principle, operation process and application cases of the coating machine, this paper aims to provide reference and guidance for researchers in the field of photosensitive resins. With the continuous development of photosensitive resin technology and the continuous improvement of the performance of the coating machine, it is believed that the application of the coating machine in the field of photosensitive resin will be further expanded and deepened.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Film Applicator in PEM Research and Preparation

- 8Application of Film Applicator in PVDF-HFP Material Research

- 9Application of Film Applicator in Cosmetic Base Body