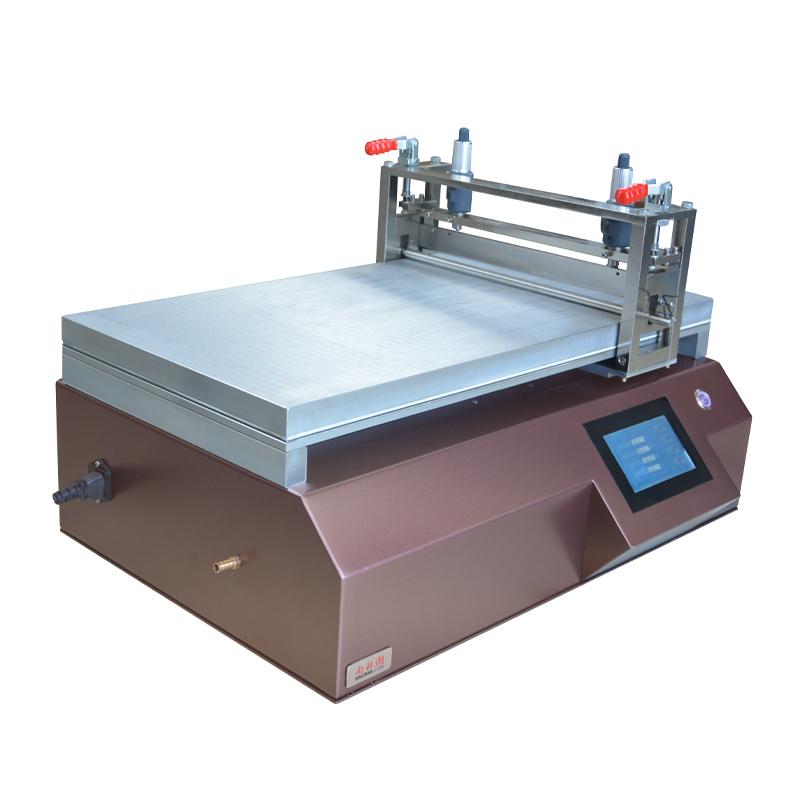

Fuel cell doctor blade Film Applicator: Working Principle and Application

As a clean and efficient energy conversion technology, fuel cells have a wide range of application prospects in the energy field. In the preparation process of fuel cells, the scraper coating machine, as one of the key equipment, plays an important role. This article will discuss in depth the technical principles, workflows, key parameters and applications of fuel cell scraper coaters, aiming to provide reference and guidance for researchers in related fields.

1. Introduction

Fuel cell is an efficient energy conversion technology that uses chemical energy to directly convert into electrical energy, which has the advantages of zero emission, high energy efficiency, and environmental protection, and is widely used in transportation, energy storage, mobile equipment and other fields. In the preparation process of fuel cells, the scraper coating machine is one of the key equipment used to coat the electrode material, which affects the quality and performance of the electrode. In this article, we will discuss the technical principles, workflow, key parameters and applications of fuel cell scraper coaters.

2. Technical Principles

The fuel cell scraper coater achieves uniform coating of electrode materials through the coating system of the coating head, ensuring the quality and performance of the electrode layer during coating, drying and curing, and quality inspection. The working principle of the fuel cell drawdown blade coater mainly involves the following key steps:

The fuel cell scraper coater is a key piece of equipment used to coat electrode materials during fuel cell preparation. Its working principle is based on the coating system of the coating head, which mainly includes several key steps of electrode material supply, coating process, drying and curing, and quality inspection.

First, the electrode material is supplied in the form of a slurry to the coating system of the squeegee coater. These electrode materials are usually composed of catalysts, conductive materials, additives, etc., with specific compositions and proportions. In the supply process, it is necessary to ensure the uniformity and stability of the electrode material to ensure the quality of the coating.

Next, the coating head is the heart of the squeegee applicator and is responsible for evenly coating the electrode material on the conductive substrate. During the coating process, the coating head is equipped with a squeegee that evenly coats the electrode material on the surface of the substrate to form a thin film. Parameters such as the angle of the blade, the contact pressure between the blade and the substrate, and the coating speed need to be precisely controlled to ensure that the thickness and uniformity of the coating meet the requirements.

Once coated, the coated substrate needs to be dried and cured to form a strong electrode layer. Typically, the coated substrate passes through an oven or drying chamber to evaporate the solvent in the electrode material by heating or other means, allowing the electrode material to solidify on the substrate to form a film. The temperature and time of drying and curing need to be adjusted according to the nature and requirements of the electrode material to ensure the quality and stability of the electrode layer.

Finally, the prepared electrode material needs to be inspected and evaluated for quality, including checking the coating thickness, uniformity, surface flatness and other indicators. These tests can help confirm whether the quality of the electrode layer meets the preparation requirements and application requirements, thereby ensuring the performance and stability of the fuel cell.

3. Applications

Fuel cell scraper coater plays a vital role in the fuel cell preparation process, and its application is mainly reflected in the following aspects:

Electrode Preparation:The anode and cathode of a fuel cell are composed of electrode materials, and the scraper coater is used to evenly coat the electrode material on the conductive substrate to form an electrode layer. Through the precise control of the squeegee coating machine, the uniform coating of the electrode material can be realized, ensuring that the thickness and uniformity of the electrode layer meet the requirements.

Quality control:Drawdown blade coaters play a key quality control role in fuel cell preparation. By adjusting the squeegee angle, squeegee pressure and other parameters, the coating thickness and uniformity of the electrode material can be controlled to ensure that the quality of the electrode layer meets the preparation requirements. Strict implementation of quality control can improve the performance and stability of the electrode.

R&D:The fuel cell scraper coater provides important support for the research and development of new materials. The continuous innovation and development of fuel cell technology requires electrode materials with excellent performance, and the squeegee coating machine can be used to prepare various types of electrode materials on a laboratory scale, which provides convenient conditions for the research and development of fuel cell technology.

Production:For industrial-scale fuel cell production, the squeegee coater can achieve mass production, improving production efficiency and product quality. Through the automatic control system, the drawdown blade coater can achieve continuous and stable coating operation to meet the needs of large-scale production.

Customized production:The fuel cell squeegee applicator is flexible and can be customized to meet the requirements of different electrode materials. By adjusting the coating parameters and squeegee design, different types and specifications of electrode materials can be adapted to meet the needs of different users.

4. Conclusion

As a key equipment in the preparation process of fuel cells, the fuel cell scraper coating machine has an important impact on the coating quality and performance of electrode materials. Through an in-depth discussion of its technical principles, workflows, key parameters and applications, this paper aims to provide reference and guidance for researchers in related fields to promote the development and application of fuel cell technology.

- 1Kinetic control of silicon carbon cathode Spreader drying: key technology to solve crazing and powder drop

- 2How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 3NVP anode film FAQ and solution

- 4Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 5Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 6Application and selection of laboratory coater in PDMS thin film prepative

- 7Scraping machine selection case: film substrate large size high accuracy scraping solution

- 8Drawdown blade Film Applicator Coating UV glue on film

- 9Using the drawdown blade Automatic Film Applicator to prepare Resin on Release Paper