Experimental Study on Spreader Lithium Ion Separator on PP Material for Doctor blade coater

Summary

The purpose of this study was to investigate the selection experiment of a scraper coater for coating lithium-ion battery separators on polypropylene (PP) materials. Through the comparison and analysis of different types of scraper coaters and their parameters, combined with the characteristics of lithium-ion battery separators of different materials, the model of scraper coater suitable for coating on PP material was selected. The experimental results show that the lithium-ion battery separator can be uniformly and stably coated on PP material under the conditions of the selected scraper coater, which provides a reference and guidance for the production process of lithium-ion batteries.

Keywords: scraper coater, polypropylene, lithium-ion battery, separator, selection experiment

Introduction

With the wide application of electronic products such as electric vehicles and smartphones, lithium-ion batteries have received widespread attention as an important energy storage device. The performance of lithium-ion batteries is closely related to their internal structure, in which the separator, as an important part of the battery, plays a key role in the performance and safety of the battery. As a commonly used coating equipment, the drawdown blade coater plays an important role in the preparation process of lithium-ion battery separators.

As a common polymer material, polypropylene (PP) has good chemical, mechanical and thermal stability, so it is widely used in the preparation of lithium-ion battery separators. In this paper, we will discuss the model and parameter setting of the scraper coater suitable for the process through the selection experiment of the scraper coater coating lithium-ion battery separator on PP material, so as to provide reference and guidance for the production process of lithium-ion batteries.

Scraper coater and analysis of its parameters

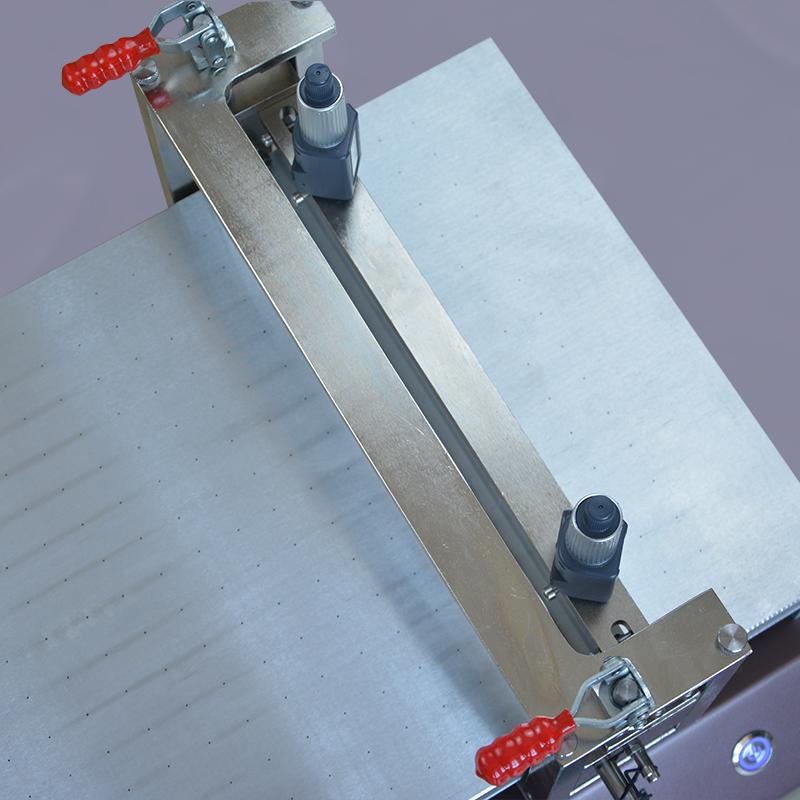

Scraper coating machine is a common coating equipment, which is mainly composed of coating roller, scraper, feeding device, electronic control system, etc. During the coating process, the coating roller applies the coating liquid to the surface of the substrate, and the scraper controls the thickness of the coating layer by adjusting the gap. The selection of the squeegee coater needs to consider the characteristics of the coating material, the coating speed, the coating thickness and other factors.

In view of the demand for coating lithium-ion battery separators on PP materials, it is necessary to select a squeegee coater suitable for high-viscosity and high-dryness liquids. Common types of squeegee coaters include manual, semi-automatic and fully automatic, among which the fully automatic squeegee coater has the advantages of fast coating speed and high precision of coating thickness control, which is suitable for industrial production environments.

Lithium-ion battery separator characterization analysis

As an important part of the battery, the main function of the lithium-ion battery separator is to isolate the positive and negative electrode materials, prevent short circuits, and allow the transmission of lithium ions. The performance of the separator directly affects the safety, cycle life and energy density of the battery.

When coating lithium-ion battery separators on PP materials, the following key characteristics need to be considered:

Porosity: The porosity of the separator determines the transmission rate of lithium ions, too high porosity will lead to the leakage of electrolyte inside the battery, and too low porosity will affect the diffusion rate of lithium ions.

Thickness: The thickness of the separator directly affects the internal resistance and energy density of the battery, and the separator is usually required to have a small thickness but sufficient mechanical strength.

Thermal stability: Lithium-ion batteries are prone to thermal runaway under high temperature conditions, so the separator needs to have good thermal stability and be able to maintain structural stability within a certain temperature range.

Experimental Design and Methods

In this experiment, a fully automatic scraper coater was selected, and the coating speed and coating thickness were controlled by adjusting the parameters of the coating roller and scraper. The coating solution is a polymer solution to simulate the coating process of lithium-ion battery separators.

The experimental procedure is as follows:

Prepare the squeegee coater and coating liquid, and adjust the parameters of the coater according to the experimental requirements.

Place the PP substrate on the coater and start the coater to start the coating process.

According to the experimental plan, adjust the coating speed and scraper gap of the coater to control the thickness of the coating layer.

After coating, the coated PP substrate is removed for performance testing and analysis.

Experimental results and analysis

Through experimental observation and testing, samples of PP substrate coated at different coating speeds and squeegee gaps were obtained. The samples were characterized and analyzed by scanning electron microscopy, porosity test, thickness measurement and other means.

The experimental results show that within a certain range, the coating speed has a great influence on the thickness of the coating layer, too fast will lead to uneven coating layer, and too slow speed will cause too long coating time. The adjustment of the squeegee gap has a great impact on the thickness of the coating layer and the surface flatness, too large a gap will cause the coating layer to be too thick, and too small a gap will lead to uneven coating.

In addition, the porosity, thickness, thermal stability and other data of the coating layer were obtained by testing the performance of PP substrate under different coating conditions, which provided a reference for further optimizing the parameters of the scraper coater.

Conclusions and prospects

In this study, the model and parameter setting of the scraper coater suitable for the process were discussed through the selection experiment of the scraper coater coating lithium-ion battery separator on PP material. The experimental results show that the lithium-ion battery separator can be evenly and stably coated on PP material under the conditions of the selected scraper coater. In the future, the coating machine parameters can be further optimized, the coating efficiency and coating quality can be improved, and technical support can be provided for the improvement and optimization of the lithium-ion battery production process.

- 1Kinetic control of silicon carbon cathode Spreader drying: key technology to solve crazing and powder drop

- 2Application and selection of laboratory coater in PDMS thin film prepative

- 3Application of doctor blade coater in electrode and solid electrolysis preparation

- 4Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 5Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 6Several Common Experimental Spreader Methods and Their Applications

- 7Application of laboratory coater coating aluminum oxide paste on PET film

- 8Experimental test of performance of epoxy resin film coated on metal iron plate by small coater

- 9Method and application of experimental coater coating water-based slurry on aluminum foil