Application of laboratory coater in EVA hot-melt adhesive

Laboratory small coaters play an important role in modern industry, especially in the application of coating materials. This article will discuss the technical features, benefits, and challenges of laboratory small coaters in EVA (ethylene vinyl acetate copolymer) hot melt adhesive applications. We will introduce the basic characteristics of EVA hot melt adhesive, and analyze the key parameters and operation skills of the laboratory small coating machine in the EVA hot melt adhesive coating process。

1. Introduction

EVA hot melt adhesive is a thermoplastic adhesive widely used in packaging, construction, automotive and other fields, with excellent adhesion performance and processability. Coating is a crucial step in the application of EVA hot melt adhesives. As an efficient and flexible coating equipment, laboratory small coaters are widely used in the preparation and R&D of small batch samples. In this paper, we will discuss the technical characteristics and application prospects of laboratory small coaters in EVA hot melt adhesive coating.

2. Characteristics of EVA hot melt adhesive

EVA hot melt adhesive is a thermoplastic adhesive made from the copolymerization of ethylene and vinyl acetate, which has the following key properties:

EVA hot melt adhesive has good adhesion properties and can bond a variety of substrates, such as paper, plastic, wood, etc.Rapid cooling and curing after application has the advantage of fast production cycles.EVA hot melt adhesives remain stable within a certain temperature range, making them suitable for applications in high-temperature environments.Properties such as viscosity and curing speed can be adjusted by adjusting composition and process parameters to meet different application needs.

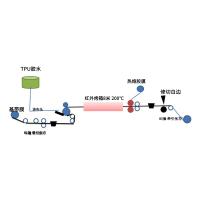

3. Technical characteristics of laboratory small coater in EVA hot melt adhesive application

The laboratory mini coater has the following technical characteristics in EVA hot melt adhesive applications:

Precise Control: The laboratory small coater has a sophisticated temperature control system and coating thickness adjustment device for precise control of the coating process.

Flexibility: Parameters such as coating speed, temperature, and pressure can be adjusted according to experimental needs to suit different material and process requirements.

Small sample preparation: It is suitable for the preparation and research and development of small batches of samples, and provides convenient conditions for laboratory research.

High Performance: With efficient coating speed and fast reaction time, it can improve the efficiency of experiments.

4. Key parameters and operation skills of laboratory small coater in EVA hot melt adhesive coating process

In a small laboratory coater, the following key parameters and operating techniques are required to achieve effective application of EVA hot melt adhesives:

Temperature control: Ensure that the temperature of the coater is stable in the appropriate range to ensure the flow and curing speed of the hot melt adhesive.

Coating speed: Adjust the coating speed according to the coating material and process requirements to ensure uniform coating and moderate speed.

Pressure control: Control the pressure of the coating roller to match the viscosity of the coating material and the coating thickness to avoid uneven coating or missed coating caused by too high or too low pressure.

Substrate Treatment: Appropriate treatment of the substrate before coating, such as cleaning the surface, adjusting the surface tension, etc., to improve the coating effect and bond strength.

5. Advantages and Challenges of Laboratory Small Coaters in EVA Hot Melt Adhesive Applications

Laboratory Compact Coaters offer many advantages in EVA hot melt applications, such as flexibility and ease of operation, but they also face some challenges:

The advantages are:The coating parameters can be flexibly adjusted according to the experimental needs, suitable for different experimental conditions and material requirements.It is suitable for the preparation and research and development of small batches of samples, and provides convenient conditions for laboratory research.With efficient coating speed and fast reaction time, it can improve the efficiency of experiments.

The challenge is:Laboratory small coaters may have uneven coating during the coating process, which needs to be solved by reasonable adjustment of parameters and operation skills.Due to the limitations of equipment size and process characteristics, laboratory small coaters may not be able to meet the needs of large-scale production.Operating a small coater in the laboratory requires a certain amount of technical experience and operating skills.

conclusion

Laboratory small coaters play an important role in EVA hot melt adhesive applications, offering high flexibility and ease of operation. Through reasonable control of coating parameters and operation skills, the effective coating of EVA hot melt adhesive can be realized, which provides convenient conditions for scientific research work.

- 1Application of laboratory coater in LED fluorescent film Spreader

- 2Application and selection of laboratory coater in PDMS thin film prepative

- 3Experimental Study on High Viscosity Ultraviolet Resin Coating on Glass Substrate by Small Coater

- 4Application of doctor blade coater in electrode and solid electrolysis preparation

- 5Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 6Experimental application of water-based paints on film laminating paper by laboratory coater

- 7Experimental coater application case video of liquid silica gel on release paper

- 8Laboratory small coater coated with polyester film on ultra-thin PET film [video demonstration]

- 9Technical Requirements and Application of Lithium Battery Slurry Coated on Copper Foil for Small Coater