Application technology and optimization of wire-rod Film Applicator on non-woven fabric

Summary:

This article introduces the application technology of the wire rod coating machine for coating glue on non-woven fabrics. Firstly, the wide application of non-woven fabrics in various fields and their importance in the manufacturing industry are introduced. Then, the working principle and structure of the wire rod coating machine are described in detail. Then, the optimization of operating parameters when applying glue is discussed, including glue concentration, coating speed and pressure, etc. Finally, the application effect of the wire rod coating machine on non-woven fabrics and its potential application in the manufacturing industry were demonstrated through experimental cases.

1. Introduction

Non-woven fabric is a kind of non-woven material made of staple fiber or filament through textile machinery, which has the characteristics of softness, breathability, water absorption, wear resistance, etc., and has a wide range of applications in medical, home, automotive, construction and other fields. The coating glue is one of the important process links in the manufacture of non-woven fabrics, which can enhance the bonding and functionality of non-woven fabrics.

2. Application of non-woven fabrics in the manufacturing industry

Non-woven fabrics are widely used in medical and health products, household products, automotive interiors, building materials and other fields. For example, the manufacture of medical supplies such as medical masks, surgical gowns, and sanitary napkins is inseparable from the application of non-woven fabrics. In addition, non-woven fabrics are also used in household items such as bedding, curtains, etc., as well as automotive interior materials and building waterproofing materials.

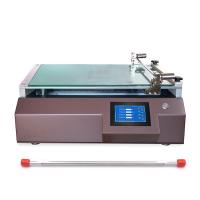

3. The working principle and structure of the wire rod coating machine

Wire rod coating machine is a commonly used coating equipment, by setting a coating wire rod on the coating head, the glue is evenly coated on the surface of the substrate. It works similarly to a glue pen, but allows for a wider, more uniform application. The wire rod coater usually consists of a coating system, a conveying system and a control system.

4. Optimization of operating parameters for glue application

4.1 Glue concentration

The glue concentration directly affects the thickness and uniformity of the glue film after coating. A higher glue concentration may result in an overly thick coating, while a lower concentration may result in an uneven coating. Therefore, the glue concentration needs to be adjusted according to the actual demand.

4.2 Coating speed

Coating speed refers to the speed at which the coating head moves in the coating system, which affects the coating thickness and uniformity of the glue. It is often necessary to adjust the coating speed according to factors such as the rheology of the glue and the adsorption of the substrate to obtain the best coating effect.

4.3 Pressure control

During the coating process, proper pressure can help the glue evenly spread on the surface of the substrate and ensure the compactness and adhesion of the coating. Therefore, it is necessary to adjust the pressure of the coating head according to the viscosity of the glue and the characteristics of the substrate.

5. Experimental case: application of glue coating machine on non-woven fabric

In the experiment, we used a wire rod coater to evenly coat different concentrations of glue on the non-woven substrate, and optimized the coating process by adjusting parameters such as coating speed and pressure. The results show that the optimized coating glue has good uniformity and adhesion, which is suitable for various process needs in the manufacture of nonwovens.

6. Conclusion

The application of wire rod coating machine in the manufacture of non-woven fabrics is of great significance, which can effectively control the coating process and improve the quality and efficiency of coating. By optimizing the coating parameters, non-woven products with good performance can be obtained, which promotes the development and application of the manufacturing industry.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Film Applicator in PEM Research and Preparation

- 8Application of Film Applicator in PVDF-HFP Material Research

- 9Application of Film Applicator in Cosmetic Base Body