Technical application of laboratory coater coating adhesive on PET film

Summary:

In this paper, the technical application and optimization method of applying adhesive on PET film by laboratory coater are discussed. Firstly, PET film and its wide application in industry are introduced, and then the principle and process of coating machine applying adhesive to PET film are elaborated. Then, the problems that may be encountered in the coating process are analyzed, and solutions are proposed. Finally, the advantages and future development direction of coating machine technology in PET film are summarized.

Background

PET film, i.e. polyethylene terephthalate film, is an excellent plastic material with excellent mechanical properties, heat resistance, transparency and chemical stability, which is widely used in food packaging, electronic products, medical equipment and other fields. In the production process of PET film, in order to improve its surface adhesion and printing performance, it is often necessary to apply a layer of adhesive on its surface.

Coating machine principle and process

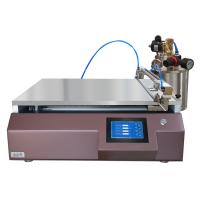

A laboratory coater is a device used to evenly coat liquid materials on substrates such as film, paper, etc. The principle of the coating machine is to evenly coat the adhesive on the surface of the substrate through a coating rod or coating squeegee, and then go through a drying or curing process to form an adhesive layer. The process mainly includes the preparation of coating slurry, the setting of coating parameters, the control of the coating process, and the drying or curing treatment.

Problems and solutions that may be encountered in the coating process

In the process of applying adhesives in laboratory coaters, there may be some problems, such as uneven adhesives, inconsistent coating thicknesses, and too fast or slow application speeds. In order to solve these problems, we can adjust the speed of the coating roller, adjust the coating pressure, and optimize the formulation of the coating slurry.

Technical advantages and development direction

The laboratory coating machine has the advantages of easy operation, low cost and good controllability to apply adhesive on PET film, which can meet the needs of small batch trial production. In the future, with the continuous development and improvement of coating technology, the process of coating machine applying adhesive on PET film will be more efficient and accurate, providing technical support for the further promotion and application of PET film in various application fields.

Conclusion:

The technical application and optimization of laboratory coating machine for applying adhesive on PET film is of great significance for improving the surface performance and functional application of PET film. By reasonably adjusting the coating parameters and optimizing the process flow, the uniform coating of the adhesive on the PET film can be realized, which provides technical support and guarantee for the application and expansion of PET film in the fields of food packaging, electronic products, medical devices and other fields.

- 1Application of laboratory coater in LED fluorescent film Spreader

- 2Application and selection of laboratory coater in PDMS thin film prepative

- 3Application of doctor blade coater in electrode and solid electrolysis preparation

- 4Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 5Experimental application of water-based paints on film laminating paper by laboratory coater

- 6Experimental coater application case video of liquid silica gel on release paper

- 7Laboratory small coater coated with polyester film on ultra-thin PET film [video demonstration]

- 8Application of small coater in gel coating

- 9Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane