Selection and Application of Laboratory Film Applicator in Wooden ground floor film laminating

Summary:

The purpose of this paper is to discuss the selection and application of laboratory film coaters in the process of laminating wood floors. Taking the 140mm300mm30mm wood base floor as the research object, combined with the vacuum adsorption wire rod scraper heating integrated film coating machine, hot melt adhesive and PVC film were used for lamination. Through experimental verification, the film coating machine can achieve efficient lamination of the floor, ensure uniform and firm adhesion of the coating, and provide a feasible process solution for the production of wood flooring.

Keywords: laboratory film coating machine; wood floor lamination; Lectotype; applied inquiry; hot melt adhesives; PVC film

introduction

As a common interior floor decoration material, wood flooring has a wide range of applications in the decoration and construction industry. In order to improve the service life and aesthetics of wood flooring, it is often necessary to laminate it. In this paper, the laboratory coating machine will be used as a tool to discuss the selection and experimental application of laminating film on wood flooring, in order to provide an efficient and accurate coating process scheme for floor production.

Selection and principle of coating machine

2.1 Selection of film coating machine

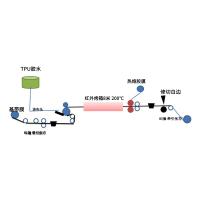

In response to the needs of wood floor lamination, a vacuum adsorption wire rod scraper is used to heat the integrated film coating machine. This model has a vacuum adsorption function, which can adsorb and flatten the PVC film; At the same time, it is equipped with a heated table and a hot melt adhesive system, which can evenly coat the hot melt adhesive on the film.

2.2 How it works

The Film Applicator first adsorbs the PVC film on the heated table surface through the vacuum adsorption function to ensure that it is flat and laminated. Subsequently, the coater melts the hot melt adhesive and evenly applies it to the surface of the PVC film, and then places the wooden floor on the PVC film coated with the hot melt adhesive to bond it to the film.

Experimental applications

3.1 Experimental preparation

Before the experiment begins, prepare the wood floor sample and the required materials such as PVC film and hot melt adhesive. According to the experimental requirements, adjust the working parameters of the coating machine, including heating temperature, coating film thickness, etc.

3.2 Experimental Procedure

Turn on the coater and place the wooden floor on the heated countertop.

Activate the vacuum adsorption function to adsorb the PVC film on the surface of the wooden floor.

Start the hot melt adhesive system so that it evenly spreads the hot melt adhesive onto the PVC film.

Another piece of PVC film is placed on top of the PVC film coated with hot-melt adhesive.

Wait for the hot melt adhesive to solidify and allow the wood floor to bond with the PVC film.

3.3 Experimental results

After experiments, the wood floor is well bonded with PVC film, evenly coated, and there are no bubbles, wrinkles and other phenomena. After testing, the coating thickness meets the requirements, and the adhesive strength of the hot melt adhesive and the wood floor is high, achieving the expected effect.

Conclusions and prospects

The experimental results show that the integrated film coating machine heated by vacuum adsorption wire rod scraper has high efficiency and accuracy for laminating on wooden floors. The coater ensures uniform and firm adhesion of the coating, providing a viable coating process for wood flooring production. In the future, the design and process parameters of the coating machine can be further optimized, the production efficiency and the quality of the lamination can be improved, and the production needs of wood flooring with different specifications and requirements can be met.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Laboratory Automatic Film Applicator in Coating Battery Slurry on Copper Foil and Aluminum Foil

- 8Application of Film Applicator in PEM Research and Preparation

- 9Application of Film Applicator in PVDF-HFP Material Research