Describe 4 Common Stirrers in detail

The stirrer is an important equipment used for solid-liquid and liquid-liquid mixing and stirring in the laboratory, and plays a key role in many fields such as biology, physical and chemical, cosmetics, health care products and food. There are four main types of agitators on the market: manual, electric, magnetic and pneumatic, each with its own characteristics and applicable scenarios.

Hand blender

Hand mixers are typically used for small-scale operations and are suitable for homes or labs with smaller throughputs. Since the operation requires a large amount of manpower, it is less efficient in the case of large-scale production or long-term operation.Hand mixers are typically used for small-scale experiments or home use, and are simple and inexpensive to operate. However, due to the human input, the processing volume is small and relatively inefficient. Therefore, it is suitable for simple mixing operations, such as food preparation or small chemical experiments at home.

Electric agitator

The electric stirrer is suitable for scenarios with large processing capacity, and usually uses carbon brush motors with high power. It is a reliable equipment for factories, scientific research institutions, colleges and universities and medical units to carry out scientific research, product development, quality control and production process applications. The overhead agitator is a type of electric agitator, which has a larger processing capacity and uses a brushless motor, which can run for a long time, which significantly improves the experimental efficiency. Electric agitators are suitable for high-capacity scenarios and are commonly found in environments such as factories, research institutes, and university laboratories. They typically feature high-powered carbon brush motors that can run continuously for longer periods of time, providing efficient mixing and stirring, suitable for the needs of scientific research, product development and production processes.

Magnetic stirrer

Magnetic stirrers can be divided into two types: ordinary type and heating type according to the different processing capacity and function. The ordinary type magnetic stirrer adopts the design of driving stirring, has a small footprint, and is suitable for liquids or solid-liquid mixtures with low viscosity. It is widely used in chemical analysis, biological reagent mixing, and liquid handling. The heated magnetic stirrer is suitable for application scenarios with higher requirements for temperature and power, and generally adopts a double heating control loop to ensure temperature stability. Depending on the function and capacity, the magnetic stirrer is available in two options: normal type and heated type. Conventional magnetic stirrers are designed to be compact for small-scale laboratory operations, while heated magnetic stirrers are suitable for experiments that require higher temperatures, with dual heating control loops to ensure temperature stability, and are commonly found in chemical and biological experiments.

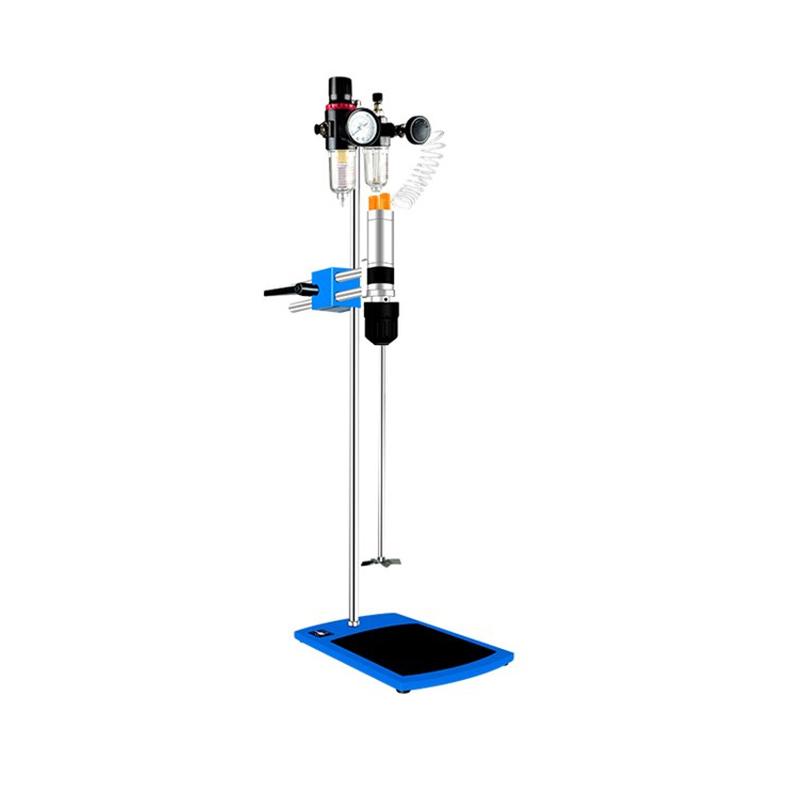

Pneumatic agitator

Pneumatic agitators use compressed air as the driving force and are suitable for handling flammable and explosive substances or paints, chemicals and solvents in high-temperature environments. It converts pressure energy into mechanical energy through the expansion of compressed gas, and realizes the stirring and mixing of samples. The pneumatic agitator uses compressed air as the power source, which is suitable for experiments with flammable and explosive substances or high-temperature environments. They provide a safe and reliable mixing solution by the expansion of compressed gases, and are commonly used in experimental operations in the chemical, paint, and chemical industries.

Choosing the right agitator type depends on the experimental needs and operating environment. When mixing and stirring, ensuring that the appropriate equipment is selected can improve work efficiency, ensure the quality of the experiment, and ensure the safety of the experiment. Whether it's a small-scale home experiment or a large-scale industrial production, there's a type of agitator to meet your needs.

- 1Comparison and Application of Magnetic Stirring and Mechanical Stirring

- 2Pneumatic Stirrer Common Failures and Solutions

- 3Application and Selection Guide of Electromagnetic Stirrer in Laboratory

- 4Principle and Application of Water Bath Magnetic Stirrer

- 5What is a mixer? Applications, advantages and disadvantages of mixers

- 6How to prepare polymer blended solid film materials?

- 7Agitators and their classification

裴梦琛 - 《西北大学》

- 8Testing Factors Affecting the Drying Properties of Plastic Water-based Gravure Ink with Agitator

- 9What are the characteristics of an overhead mixer?

-

-

-

HUXI HMS-203D magneticstirrer$ 251.00

-

Qiwei CL-R magneticstirrer 1000ml$ 103.00

-

DADI CJJ78-1 Magnetic Stirrer$ 101.00

-