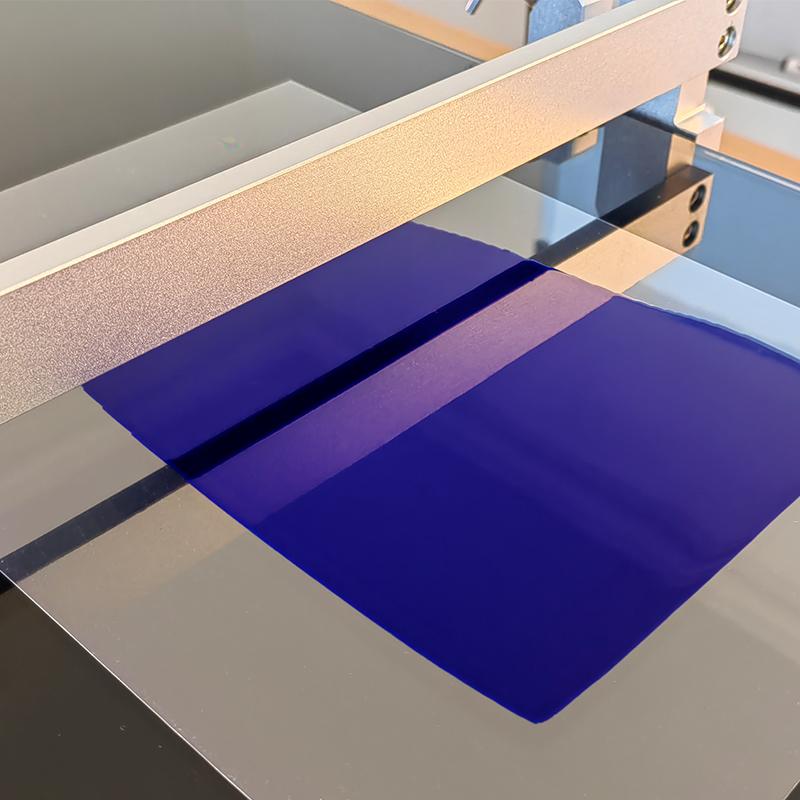

Experimental application of small laboratory coater coated with perfluorosulfonic acid on PET film

introduction

In modern materials science, perfluorosulfonic acid (PFSA) is widely used in fuel cells, electrolyte membranes and other fields due to its excellent chemical and physical properties. Polyethylene terephthalate (PET) is a common polymer material that is widely used in various industrial applications due to its excellent mechanical properties and chemical stability. In this article, we will discuss in detail the experimental methods, results, and application prospects of applying perfluorosulfonic acid to PET substrates on a small laboratory coater.

Materials & Equipment

Material:

Perfluorosulfonic acid (PFSA): An active material used for coatings with high ionic conductivity and chemical stability.

Polyethylene terephthalate (PET): Substrate material with high strength and good thermal stability.

Solvents: Water, alcohols or other suitable organic solvents are commonly used to adjust the viscosity and uniformity of the PFSA solution.

Equipment:

Laboratory Small Coater: A key piece of equipment for precise control of coating thickness and uniformity, with heating function availableDrying and curing of the film layer after application.

Drying oven: Used to cure the film under specific temperature and humidity conditions.

Viscometer: Used to measure the viscosity of the coating solution to ensure the uniformity of the solution and the appropriate coating performance.

Coating thickness measuring instrument: used to detect the thickness of the coating and ensure the quality of the coating.

Experimental Methods

1. Solution Preparation:

First, perfluorosulfonic acid is dissolved in an appropriate solvent at a certain concentration. The choice of solvent should consider its solubility to PFSA and its effect on PET. Commonly used solvents include deionized water, ethanol, etc. The concentration of the solution should be adjusted according to the expected coating thickness and uniformity, usually between 1-5%.

2. Base Preparation:

The PET substrate is cut to size and surface treated to improve the adhesion of the coating. Commonly used surface treatment methods include plasma treatment, ultraviolet ozone treatment, etc. These methods can effectively remove organic contaminants from the substrate surface and increase surface energy.

3. Coating Operation:

The prepared PFSA solution is evenly applied to the PET substrate. Small laboratory coaters typically use precision coating knives or coating rollers to control coating thickness. The choice of coating speed and pitch needs to be adjusted according to the viscosity of the solution and the expected coating thickness. In general, the coating speed is between 10 and 50 mm/s, and the coating thickness is controlled between a few microns and tens of microns.

4. Drying & Curing:

The coated PET substrate needs to be dried and cured. First, the heating function of the coater is activated, and the coated sample is placed on the coating table for preliminary drying at a temperature of 50-80 °C for 10-30 minutes. Subsequently, the samples are transferred to a Drying Oven for final curing at 150-200°C for 1-2 hours. This process helps to remove solvents and enhance the mechanical properties of the coating.

5. Performance Testing:

The performance testing of coatings includes coating thickness measurement, adhesion testing, ion conductivity testing, etc. Thickness measurements can be performed using a coating Thickness Gauge to ensure the uniformity and expected thickness of the coating. Adhesion testing is typically performed using the stripe or peel method to assess the adhesion between the coating and the substrate. Ion conductivity tests can be performed by methods such as electrochemical impedance spectroscopy.

Experimental results and discussion

1. Coating thickness and uniformity:

By adjusting the coating speed and tool pitch of the coater, precise control of the coating thickness can be achieved. In this experiment, the coating thickness was controlled between 10-20 microns, and the thickness uniformity was good. Observed by an optical microscope and a Thickness Gauge, the coating surface is smooth and there are no obvious defects.

2. Coating Adhesion:

The coating adhesion of the surface-treated PET substrate is significantly improved. The scratch test results showed that the coating had no obvious peeling and good adhesion. The substrate treated with UV ozone showed better adhesion, indicating that the surface treatment method had a significant effect on the coating performance.

3. Ionic conductivity:

The ion conductivity test results show that the PFSA coating has a high proton conductivity, which meets the expected performance indicators. Under different temperature and humidity conditions, the ionic conductivity of the coating remains stable, indicating that it has good stability in practical applications.

Application prospects

Perfluorosulfonic acid coating has a wide range of application prospects in fuel cells, electrolyte membranes and other fields. With a small laboratory coater, precise control of coating thickness and uniformity can be achieved to produce a coating product with excellent performance. In practical applications, further optimization of the coating process and solution formulation can improve the adhesion and ionic conductivity of the coating to meet higher performance requirements.

1. Fuel Cell:

Perfluorosulfonic acid coatings are used as proton exchange membranes in fuel cells to significantly improve the efficiency and longevity of batteries. By controlling the thickness and uniformity of the coating, the performance parameters of the battery can be optimized to achieve higher energy conversion efficiency.

2. Electrolyte Membrane:

In electrolyte membrane applications, PFSA coatings provide excellent ionic conductivity and chemical stability. With a small laboratory coater, the thickness and uniformity of the film can be precisely controlled, and the electrolyte film product with excellent performance can be prepared.

3. Other Industrial Applications:

PFSA coatings also have a wide range of application prospects in sensors, separation membranes and other fields. By optimizing the coating process, the performance and reliability of these products can be improved to meet the needs of different fields.

conclusion

This article describes in detail the experimental methods, results, and application prospects of applying perfluorosulfonic acid to PET substrates on a laboratory small coater. With precise control of the coating process and solution formulation, it is possible to prepare PFSA coating products with excellent performance. In practical applications, further optimization of process and material selection can achieve higher performance indicators and promote the development of related fields.

- 1Application of laboratory coater in LED fluorescent film Spreader

- 2Application and selection of laboratory coater in PDMS thin film prepative

- 3Experimental Study on High Viscosity Ultraviolet Resin Coating on Glass Substrate by Small Coater

- 4Application of doctor blade coater in electrode and solid electrolysis preparation

- 5Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 6Experimental application of water-based paints on film laminating paper by laboratory coater

- 7Experimental coater application case video of liquid silica gel on release paper

- 8Laboratory small coater coated with polyester film on ultra-thin PET film [video demonstration]

- 9Technical Requirements and Application of Lithium Battery Slurry Coated on Copper Foil for Small Coater