Function and maintenance of manual Ink Proofer

The manual color wheel metal anilox roller plays a vital role in the flexographic ink transfer system. Its design and parameters directly affect the quality and efficiency of ink transfer. This article will start with the parameter description of anilox rollers, introduce its structure and types step by step, and deeply discuss the precautions in the process of use and maintenance.

1. Parameter description of anilox roller

Number of anilox lines

The number of reticulated lines determines the number of cavities per unit length, which directly affects the quality of ink transfer. Different thread counts can have an impact on the clarity of printed graphics.

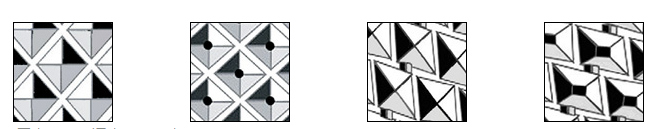

Mesh shape

Including pyramidal, quadrangular table, hexagonal platform, spiral, etc. The different shapes of the mesh affect the storage and transfer performance of the ink.

Mesh openings

Depth, opening: These parameters directly affect the storage and release of ink in the cavity, which in turn affects the uniformity and accuracy of ink transfer.

Anilox angle

Anilox rollers at different angles are suitable for different types of printing needs, such as 30°, 45°, 60°, etc.

Cavity volume

It reflects the total amount of ink that can be accommodated in the unit surface area of the anilox roller, which is directly related to the amount and quality of ink.

Second, the structure and type of anilox roller

From the structural point of view, the anilox roller is mainly composed of mesh cavities and mesh walls, and from the material point of view, it mainly includes the roller core, base material and surface coating. According to different surface coating materials, it can be divided into metal chrome plating anilox roller and ceramic anilox roller, among which ceramic anilux roller is more favored by enterprises because of its excellent performance.

3. Factors to be considered when using anilox rollers

Choose the right mesh shape - the appropriate mesh shape should be selected according to the form of ink supply and the type of ink to ensure the delivery effect and quality of the ink.

Choose the right mesh volume - the volume size directly affects the amount of ink supplied to the anilox roller, and should be selected according to the needs and details of the printed matter.

Choose the right anilox angle – Typically, a 60° hexagonal ceramic anilox roller is sufficient for most printing needs.

Choose the right number of anilox lines – The number of anilox lines should be selected taking into account the balance between the fineness of the print and the amount of ink supplied to obtain a better printing effect.

Fourth, the maintenance of anilox rollers

Regularly inspect the mesh cavities, use a mesh microscope to inspect the mesh cavities, and deal with any problems in time.

Detect the ink viscosity and clean the anilox roller to keep the ink viscosity stable, and clean the anilox roller regularly to avoid clogging.

Use a protective sleeve for anilox rollers, and use a protective sleeve for storage to keep the surface of the anilox rollers clean and play a role in buffering and absorbing vibration.

The use of high-quality scraper and magnetic filter to control the pressure between the scraper and the anilox roller, the use of magnetic filter to reduce the impurities in the ink, prolong the service life of the anilox roller.

Manual color wheel metal anilox rollers play a vital role in flexographic ink transfer systems, and their design and parameters directly affect the quality and efficiency of printed materials. Therefore, when selecting, using and maintaining anilox rollers, it is necessary to fully consider various parameters and their influences to ensure the smooth progress of the printing process and the stable improvement of printing quality.

- 1Application of Manual Ink Proofer

- 2How to choose the correct number of mesh for screen printing?

- 3How to choose these experimental coating equipment?

- 4Manual Ink Proofer

- 5Why is the curing speed of UV curing Printing ink so fast? How to ensure a reasonable speed?

- 6General characteristics and maintenance of manual Ink Proofer

- 7PK with the same parameters domestic (CN) and imported manual Ink Proofer

- 8A good manual Ink Proofer from domestic (CN)

- 9What are the advantages of Spreader?