Technical introduction of hot-melt adhesive coater

1. Overview

A skin film hot melt adhesive coating machine is a kind of equipment used to apply hot melt adhesive on skin film materials. This equipment is mainly used in the packaging industry to improve the adhesive performance of packaging materials and ensure that the packaging is firm and reliable. This article will introduce in detail the working principle, application fields, main functions and advantages of the skin film hot melt adhesive coating machine.

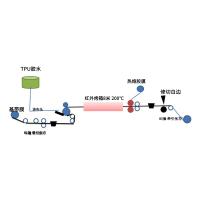

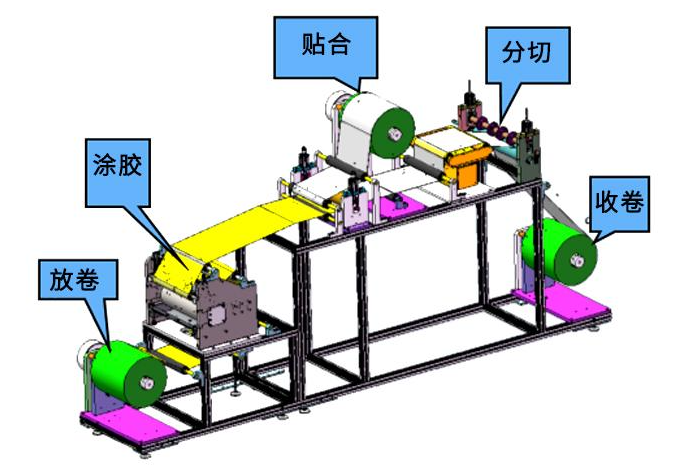

2. How it works

The working principle of the skin film hot melt adhesive coating machine mainly includes the following steps:

First of all, hot melt adhesives usually exist in solid form and need to be heated to the melting point by heating equipment to convert them to a liquid state before use. The coating machine is equipped with a heating system, which can accurately control the temperature to ensure that the hot melt adhesive melts evenly.

The melted hot melt adhesive is then evenly applied to the surface of the skin film through the applicator head. The design of the coating head and the accuracy of the control system determine the thickness and uniformity of the coating layer.

In addition, the coated skin film passes through the cooling zone, and the hot melt adhesive cures quickly during the cooling process to form a strong adhesive layer. The cooling zone is usually equipped with a cooling device to speed up the curing process of the hot melt adhesive.

Finally, after the coating is completed, the skin film is rolled into a roll through the winding device for subsequent use.

3. Applications

Skin film hot melt adhesive coating machine is widely used in the following fields:

Food packaging: It is used to package all kinds of food, such as meat, fruits, vegetables, etc., to ensure the sealing and freshness of the packaging.

Pharmaceutical packaging: In the packaging of pharmaceuticals and medical devices, the use of hot melt adhesive coating machines can improve the safety and tightness of the packaging.

Industrial product packaging: It is used for the packaging of industrial products such as electronic products and hardware tools to prevent damage during transportation.

4. Main Functions

The skin film hot melt adhesive coating machine has the following main functions:

Through the high-precision coating head and control system, the precise coating of hot melt adhesive is realized to ensure the uniformity and consistency of the coating layer.

The equipment is equipped with an advanced automatic control system, which can be parameter setting and real-time monitoring to improve production efficiency and stability.

The built-in temperature control system ensures that the temperature of the hot melt adhesive is stable during the heating, coating and cooling process, and avoids overheating or overcooling affecting the bonding effect.

Equipped with an efficient cooling device to accelerate the curing process of hot melt adhesives and increase production speed.

5. Advantages

High production efficiency: high degree of automation and fast coating speed can significantly improve production efficiency.

Cost saving: Reduce manual handling and scrap and reduce production costs.

Good bonding effect: uniform coating and firm bonding improve the quality and reliability of packaging materials.

Wide range of application: It is suitable for a variety of materials and a variety of application fields, and has a wide range of applicability.

6. Summary

Skin film hot melt adhesive coating machines play an important role in the packaging industry, providing reliable bonding solutions for a wide range of packaging materials through their efficient and precise coating technology. With the continuous advancement of technology, the skin film hot melt adhesive coating machine will play its unique advantages in more fields to help various industries improve packaging quality and production efficiency.

The above is a technical introduction to the skin film hot melt adhesive coating machine, I hope it will be helpful for you to understand and use the equipment.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Application of doctor blade coater in electrode and solid electrolysis preparation

- 3Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 4Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 5Several Common Experimental Spreader Methods and Their Applications

- 6Application of laboratory coater coating aluminum oxide paste on PET film

- 7Experimental test of performance of epoxy resin film coated on metal iron plate by small coater

- 8Method and application of experimental coater coating water-based slurry on aluminum foil

- 9Application of wire rod coater in hydrogen battery separator prepative