Study on Experimental Technique of Scraper Automatic Film Applicator Coating Adhesive on Film

introduction

In modern industrial production, coating technology has become an important part of all kinds of film processing. As an efficient coating equipment, the squeegee coating machine is widely used in the coating process of various adhesives. Through the precise control of the squeegee applicator, the adhesive can be evenly applied to the film surface, which can significantly improve the performance and quality of the product. The purpose of this experiment was to study the process and effect of squeegee coater coating adhesive on film, and to explore the influence of different coating parameters on coating quality.

Experimental materials and equipment

Experimental materials

Film substrate: Polyester (PET) and polypropylene (PP) are two common films.

Adhesive: Choose water-based acrylic adhesive, which has excellent adhesion and environmental performance.

Experimental equipment

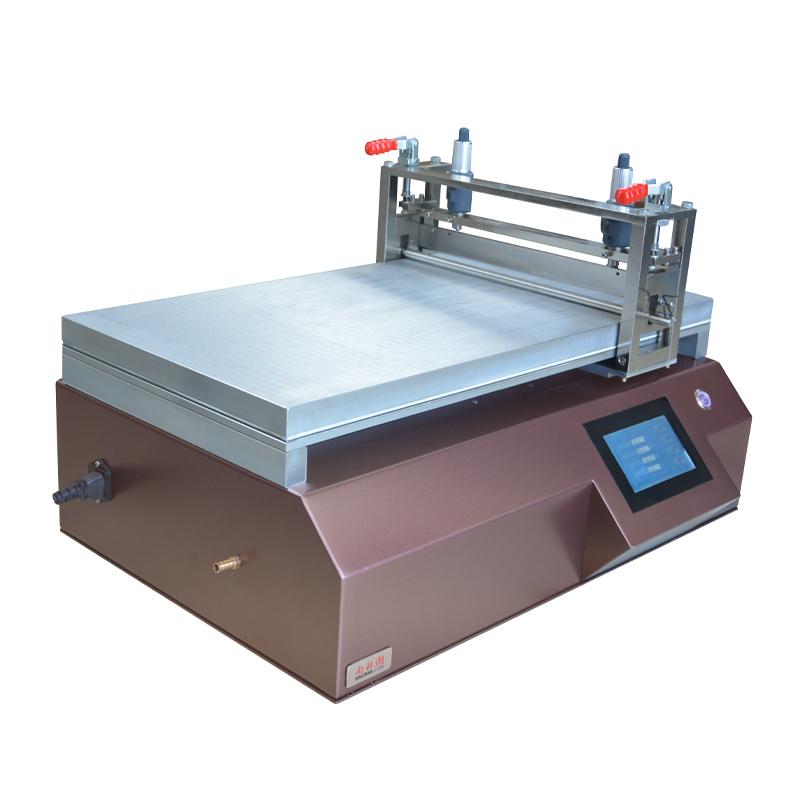

Drawdown blade coater: The equipment includes a coating blade, a transfer system, a heating system and a control system that can precisely adjust the coating thickness and speed.

Test equipment: including Tensile Testing Machines, microscopes, and Thickness Gauges to evaluate the coating effect.

Experimental Methods

Clean the surface of the film to ensure that it is dust-free and oil-free.

Fix the film on the reel of the squeegee applicator to ensure that the winding is tight and flat.

Set the operating parameters of the drawdown blade coater, including coating speed, blade gap, and heating temperature. The initial setting is 5 m/min for coating, 50 μm for scraper clearance, and 60°C for heating.

Start the coater and observe the coating process to ensure that the adhesive is evenly applied to the surface of the film.

Adjust the coating speed and blade gap to record the coating effect under different parameters.

Once coated, the film passes through a drying tunnel that allows the adhesive to dry and cure quickly.

The coated film is rewound for later use.

A tensile test was performed to test the adhesion strength of the adhesive after application.

Use a microscope to observe the uniformity and surface condition of the coating layer.

The thickness of the coating layer is measured with a Thickness Gauge to evaluate the uniformity of the coating.

Experimental results and discussion

1) Coating uniformity

Microscopic observation showed that the adhesive coating layer was relatively uniform under the initial parameter setting, and no obvious build-up or defects were found.

After adjusting the squeegee gap and coating speed, it was found that the larger the squeegee gap, the thicker the coating layer, but the uniformity was poor; The faster the coating speed, the thinner the coating layer, but it is prone to unevenness.

2) Adhesion strength

The tensile test results showed that the adhesion strength of the film was significantly improved after the adhesive was applied. At the initial parameter setting, the adhesion strength reached 4.2 N/cm.

Different blade gaps have a great effect on the adhesion strength, and the adhesion strength is the best when the scraper gap is 50 microns. Scraper gaps that are too small or too large can lead to a decrease in adhesion strength.

3) Coating thickness

The thickness measurement results show that the thickness of the coating layer is positively correlated with the blade gap. At the initial parameter setting, the coating thickness is 55 microns.

After adjusting the gap of the scraper, it is found that the larger the gap, the greater the thickness of the coating layer, but it is easy to cause the uneven coating layer; The smaller the gap, the smaller the coating thickness, but it is easy to have incomplete coating.

4) Surface condition

Microscopic observation shows that the surface of the coating layer is in good condition, with no obvious bubbles or particles.

After adjusting the coating speed, it was found that too fast would cause the coating surface to be uneven, and too slow would cause the coating layer to be too thick.

conclusion

In this experiment, the process and effect of the squeegee coater on the film were studied. By controlling the squeegee gap, coating speed and heating temperature of the film coater, the adhesive can be evenly coated and the adhesion strength of the film can be improved, while maintaining a good coating thickness and surface condition. The experimental results show that the optimal coating parameters are 5 m/min, 50 μm scraper gap, and 60°C heating temperature.

- 1Kinetic control of silicon carbon cathode Spreader drying: key technology to solve crazing and powder drop

- 2How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 3NVP anode film FAQ and solution

- 4Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 5Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 6Application and selection of laboratory coater in PDMS thin film prepative

- 7Scraping machine selection case: film substrate large size high accuracy scraping solution

- 8Drawdown blade Film Applicator Coating UV glue on film

- 9Using the drawdown blade Automatic Film Applicator to prepare Resin on Release Paper