Application Significance of Laboratory Automatic Film Applicator Scratching Polyurethane Glue

introduction

As a versatile and high-performance adhesive, polyurethane glue is widely used in industry, construction, automotive and electronics due to its excellent mechanical properties, chemical resistance and flexible processing characteristics. Under laboratory conditions, accurate and uniform application of polyurethane glues is important to study their properties, develop new formulations, and optimize processes. As a high-precision coating equipment, the laboratory coating machine can effectively improve the coating quality and experimental repeatability, and become a powerful assistant for researchers and engineers.

This article will discuss in detail the application of laboratory film coaters in polyurethane glue scraping, including equipment selection, coating process, quality control, and practical application cases, and analyze their importance in scientific research and industry.

1. The basic principle and type of laboratory coating machine

1.1 Basic Principles of Laboratory Film Coating Machine

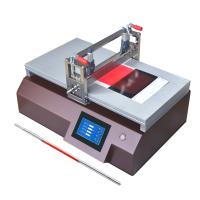

The laboratory film coater mainly applies the paint evenly to the surface of the substrate through mechanical control, and its working principle involves multiple links such as paint storage, transportation, coating and drying. A typical coater consists of a coating head, a conveyor and a control system. The coating head can be a squeegee, a wire rod or a nozzle that controls the thickness and uniformity of the coating by adjusting the height, speed and pressure of the coating head.

1.2 Types of Coating Machines

According to the different coating methods, laboratory film coating machines can be divided into the following types:

Scraper Coating Machine: Uses a scraper to evenly scrape the paint on the surface of the substrate, suitable for high-viscosity coatings, such as polyurethane glue.

Wire rod coating machine: The paint is evenly applied to the surface of the substrate by rotating the wire rod, which is suitable for low-viscosity coatings and thin film coatings.

Spraying Film Applicator: using a nozzle to atomize the paint and evenly spray it on the surface of the substrate, it is suitable for complex shapes of substrates and high-precision coatings.

Groove coating machine: The substrate is passed through the coating tank, and the coating is evenly coated on the surface of the substrate through capillary action, which is suitable for large-area coating.

Second, the characteristics and application of polyurethane glue

2.1 Characteristics of polyurethane glue

Polyurethane glues have the following remarkable properties:

Excellent mechanical properties: including high strength, high elasticity and wear resistance.

Good adhesion properties: Able to bond a wide range of materials such as metal, wood, plastics and textiles.

Chemical resistance: Good resistance to oils, solvents and acids and bases.

Flexible processing characteristics: Different curing speeds, hardnesses and viscosities can be achieved by adjusting the formulation.

2.2 Application fields of polyurethane glue

Polyurethane glues are widely used in the following fields:

Construction: For bonding and sealing floors, wall panels and roofs.

Automotive: Used for bonding and sealing body, interior and glass.

Electronics: Used for the encapsulation and bonding of electronic components.

Packaging: used for the bonding of cartons, paper bags and flexible packaging materials.

3. The process and quality control of polyurethane glue scraping by laboratory film coating machine

3.1 Process Steps

The process steps of scraping polyurethane glue on the laboratory film coating machine mainly include the following aspects:

The appropriate substrate is selected, cleaned and pre-treated to ensure the coating effect.

According to the experimental requirements, the formulation of polyurethane glue is formulated and adjusted, including viscosity, curing agent and additives.

According to the characteristics of the substrate and coating, set the coating parameters of the coater, such as scraper height, coating speed and pressure, etc.

Start the film coating machine, pass the substrate through the film coating head, and evenly coat the polyurethane glue.

Depending on the curing characteristics of the coating, select the appropriate drying and curing conditions, such as temperature, humidity and time.

Methods such as microscopes, coating Thickness Gauges, and tensile tests are used to test the uniformity, thickness, and adhesion of coatings.

3.2 Key points of quality control

In order to ensure the quality of the coating, the following points need to be noted:

Substrate cleaning and pre-treatment: Ensure that the surface of the substrate is free of oil, dust and oxides to improve coating adhesion.

Preparation and adjustment of coatings: Formulate coatings in strict accordance with the requirements of the formula, control the viscosity and curing speed to ensure the uniformity and stability of the coating.

Optimization of coating parameters: The best coating parameters are determined through experiments to ensure the thickness and uniformity of the coating.

Control of drying and curing conditions: According to the characteristics of the coating, select the appropriate drying and curing conditions to prevent the coating from cracking and peeling.

Quality inspection and feedback: regularly inspect the coating quality, adjust the process parameters and formula in time, and improve the coating effect.

Fourth, the practical application case of polyurethane glue scraping by laboratory film coating machine

4.1 Case 1: Automotive Interior Adhesive Coating

When an automobile manufacturer was developing a new interior material, it used a laboratory film coater to conduct a scraping experiment with polyurethane glue. By optimizing coating parameters and formulations, the company has successfully developed a high-strength, abrasion-resistant interior adhesive coating. The coating has undergone numerous tensile and abrasion tests to show excellent performance, significantly improving the longevity and aesthetics of interior materials.

4.2 Case 2: Packaging coating of electronic components

When an electronic manufacturing company is developing new electronic components, it uses a laboratory film coating machine to carry out polyurethane glue coating experiments. By adjusting the viscosity and curing speed of the coating, the company succeeded in developing an encapsulation coating that is resistant to high temperatures and damp heat. The coating has been tested for multiple temperature and humidity cycles, showing good resistance, effectively protecting the electronic components and prolonging the service life of the product.

4.3 Case 3: Building Seal Coating

When a construction company was developing a new type of sealing material, it used a laboratory film coating machine to carry out a scraping experiment of polyurethane glue. By optimizing the coating process and formulation, the company has successfully developed a highly elastic, weather-resistant sealcoat. The coating has undergone many aging and water tightness tests, showing excellent performance, effectively preventing leakage and aging of the building.

V. Conclusions

The application of laboratory film coating machine in polyurethane glue scraping is of great significance. Through the rational selection and use of film coating machines, the uniformity and stability of the coating can be improved, the coating process and formula can be optimized, and new coating materials with excellent performance can be developed. Laboratory film coating machines play an important role in scientific research and industry, not only improving the efficiency and accuracy of experiments, but also promoting the research and development and application of new materials.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Laboratory Automatic Film Applicator in Coating Battery Slurry on Copper Foil and Aluminum Foil

- 8Application of Film Applicator in PEM Research and Preparation

- 9Application of Film Applicator in PVDF-HFP Material Research