Application of wire rod coater in hydrogen battery separator prepative

introduction

With the growing demand for renewable energy and environmental protection, hydrogen energy has gradually attracted attention as a clean and efficient energy source. Hydrogen fuel cells have become one of the important research directions in the field of new energy due to their high energy density and zero emission. In hydrogen fuel cells, the performance of the separator directly affects the efficiency and lifetime of the battery. The preparation process of separator material determines its microstructure and performance parameters, and the wire rod coating machine, as a precise coating equipment, plays an important role in the preparation of hydrogen battery separator. This article will discuss in detail the application of wire rod coater in the preparation of hydrogen battery separators, including its working principle, operation process, influencing factors and application examples.

The working principle of the wire rod coating machine

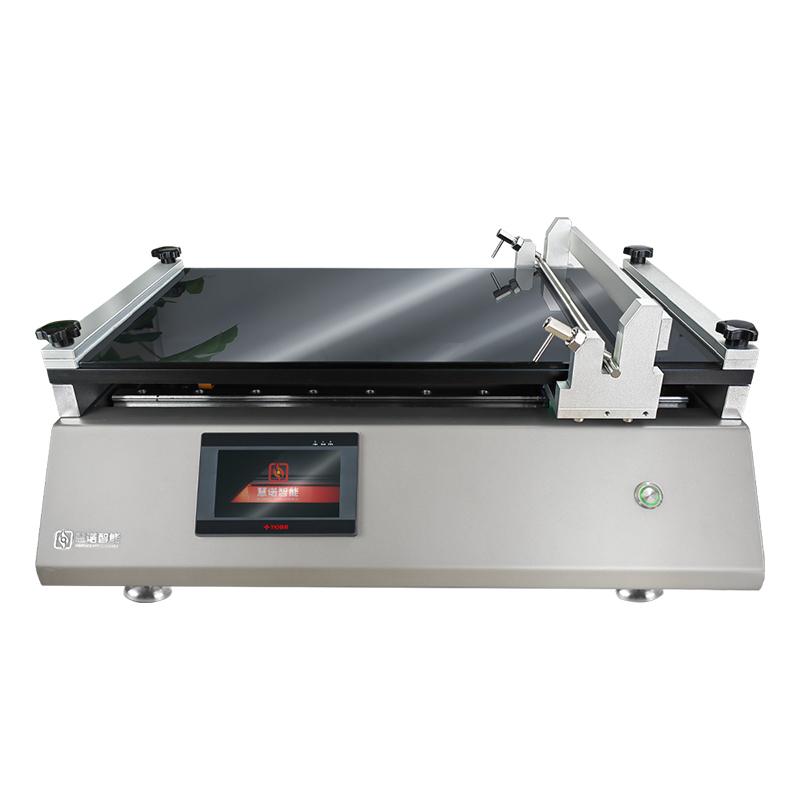

Wire rod coaters, also known as wire rod coaters or wire rod coating devices, utilize metal rods (usually stainless steel) with a certain wire diameter for coating. It works by controlling the relative movement of the metal rod to the surface of the substrate to evenly coat the coating solution on the surface of the substrate. The wire diameter and surface finish of the metal rod determine the thickness and uniformity of the coating layer.

Equipment composition

Wire rod: The surface of the metal rod has a uniform wire diameter, and its main function is to control the coating thickness.

Coating head: Install the wire rod and realize the relative motion of the wire rod to the substrate.

Substrate transfer system: control the moving speed and tension of the substrate to ensure the uniformity of the coating.

Control system: Through precise control algorithms, the coating thickness and uniformity can be adjusted.

Procedure

Preparation of coating solution: Prepare the appropriate coating solution according to the requirements of the separator material. Polymeric solutions, such as perfluorosulfonic acid membrane (PFSA) solutions, are commonly used.

Substrate preparation: Select an appropriate substrate, such as polyester film (PET), and apply a surface treatment to enhance the adhesion of the coating solution.

Coating operation: fix the substrate on the coating platform, start the equipment, make the wire rod contact with the surface of the substrate and move evenly, and the coating solution forms a uniform film on the substrate.

Dry curing: After coating, the coating layer is cured by heat or ultraviolet light irradiation to form a stable separator material.

Factors that affect the quality of the coating

Line bar parameters

Wire diameter: The choice of wire diameter directly determines the thickness of the coating layer. The optimal wire size is usually determined experimentally to meet the performance requirements of the diaphragm.

Surface finish: The finish of the surface of the wire rod affects the fluidity and uniformity of the coating solution, the smoother the surface, the more uniform the coating layer.

Coating solution properties

Viscosity: The viscosity of the coating solution affects its fluidity and the uniformity of the coating layer. Viscosity that is too high or too low can result in uneven coating.

Surface tension: The surface tension of the coating solution affects its spreadability on the surface of the substrate, and the right surface tension helps to form a uniform coating layer.

Operational parameters

Coating speed: The coating speed affects the thickness and uniformity of the coating layer. Experiments are often required to determine the optimal coating speed.

Drying conditions: The drying temperature and time affect the curing quality of the coating layer. It is necessary to select appropriate drying conditions according to the characteristics of the coating solution and the requirements of the separator.

Substrate properties

Surface treatment: The treatment of the surface of the substrate (e.g., plasma treatment, chemical treatment) affects the adhesion of the coating solution and the uniformity of the coating layer.

Substrate type: The physical and chemical properties of different substrates affect the spreading and curing behavior of the coating solution.

Application examples

Preparation of perfluorosulfonic acid ion membrane separators

Material selection: Perfluorosulfonic acid ion membrane (PFSA) is used as the coating solution, and the base material is polyester film (PET).

Coating process: using a wire rod with a wire diameter of 0.2 mm, the coating speed is 5 mm/s, and the viscosity of the coating solution is 500 mPa·s. Dry at 80 °C for 1 h after coating.

Performance test: The thickness, porosity, ionic conductivity and other performance indicators of the separator obtained by the test show that its performance meets the requirements of hydrogen fuel cell.

Preparation of polyvinylidene fluoride (PVDF) separators

Material selection: PVDF is used as the coating liquid, and the base material is polyimide (PI) film.

Coating process: A wire rod with a wire diameter of 0.3 mm was used, the coating speed was 10 mm/s, and the viscosity of the coating solution was 800 mPa·s. Dry at 100 °C for 30 min after coating.

Performance test: The thickness of the separator, mechanical strength, electrochemical stability and other performance indicators obtained by the test show that it is suitable for the use of high-performance hydrogen fuel cells.

conclusion

The wire rod coating machine has important application value in the preparation of hydrogen battery separators. It ensures the stability of the separator by precisely controlling the thickness and uniformity of the coating layer. Factors that affect coating quality include wire rod parameters, coating fluid properties, operating parameters, and substrate properties, which need to be optimized for specific applications. In this paper, the practical application effect of wire rod coating machine in the preparation of hydrogen battery separator is illustrated by specific examples, which provides a reference for future related research and application.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Application of doctor blade coater in electrode and solid electrolysis preparation

- 3Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 4Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 5Several Common Experimental Spreader Methods and Their Applications

- 6Application of laboratory coater coating aluminum oxide paste on PET film

- 7Experimental test of performance of epoxy resin film coated on metal iron plate by small coater

- 8Method and application of experimental coater coating water-based slurry on aluminum foil

- 9Technical introduction of hot-melt adhesive coater