Method and application of experimental coater coating water-based slurry on aluminum foil

introduction

As an important tool in modern materials science research, experimental coaters are widely used in the field of coating technology and material development. In particular, aluminum foil, as a common substrate, has a wide range of applications in packaging, battery manufacturing, etc. As an environmentally friendly coating material, water-based slurry has the advantages of low VOC (volatile organic compound) emissions, easy operation and good coating performance. This article will introduce in detail the method and application of the experimental coater to coat aqueous slurry on aluminum foil, covering equipment selection, process parameters, coating performance and practical application cases.

Device selection

When choosing an experimental coater, there are several factors to consider:

1. Coating type

According to the requirements of the coating and the nature of the slurry, the experimental coating machine is mainly divided into wire rod coating machine, rotary coating machine, knife coating machine and scraper coating machine. For water-based slurries, wire rod coaters and scraper coaters are more commonly used.

2. Coating uniformity

The coater should be able to provide high-precision coating thickness control to ensure the uniformity of the coating. The precision wire rod coating machine can achieve high-precision coating thickness by controlling the diameter and groove depth of the wire rod.

3. Temperature control

Aqueous slurries require suitable temperature conditions during the coating and drying process, so the coater should be equipped with temperature control to ensure the performance of the coating.

4. Substrate adaptability

Aluminum foil as a substrate requires a coater with good substrate adaptability and a stable coating operation on thin and flexible aluminum foil.

Coating process

1. Substrate treatment

Before coating, the aluminum foil substrate needs to be properly finished. Common surface treatment methods include cleaning, degreasing, and surface activation. Cleaning removes dirt and grease from the surface, oil removal improves the adhesion of the coating, and surface activation enhances the adhesion of the coating.

2. Slurry preparation

The preparation process of aqueous slurry includes dispersion, mixing, and modulation. Dispersion is to evenly distribute solid particles in the liquid, mixing is to evenly mix various components, and modulation is to adjust the viscosity and rheology of the slurry. The preparation process of the slurry needs to be strictly controlled to ensure the quality of the coating.

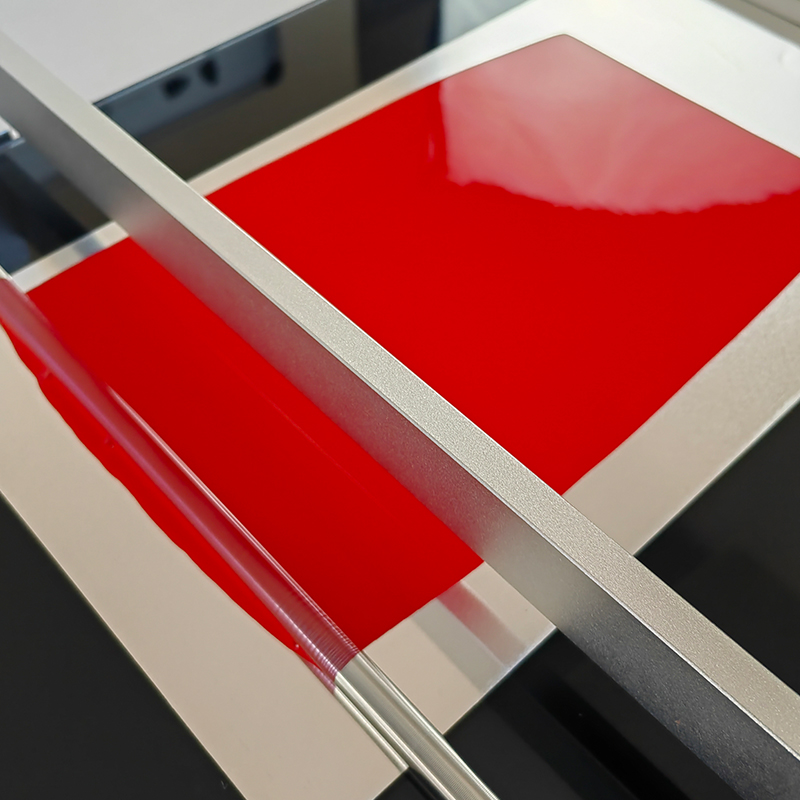

3. Coating parameters

Coating parameters include coating speed, coating thickness, wire rod diameter and coating temperature, etc. The coating speed directly affects the thickness and uniformity of the coating, and a lower speed is usually used to ensure the flatness of the coating. The coating thickness is determined by the diameter of the wire rod and the viscosity of the slurry, and the coating temperature needs to be adjusted according to the nature of the slurry.

4. Drying and curing

After the aqueous slurry is coated, it needs to be dried and cured. The drying process can be done by air drying, infrared drying or hot air drying, and curing is done by temperature and time control. The process of drying and curing is critical to the performance of the coating and needs to be precisely controlled.

Coating properties

1. Adhesion

Coating adhesion is an important indicator of coating quality. The adhesion of the coating to the aluminum foil can be evaluated by means of a tensile test or a scratch test. A good quality coating should have good adhesion and not easily peel off.

2. Abrasion resistance

The wear resistance of a coating refers to the ability of a coating to resist damage under friction and wear conditions. Abrasion resistance tests can be performed through abrasion tests to evaluate the durability of the coating in real-world use.

3. Corrosion resistance

Aluminum foil coatings need to be corrosion-resistant in some applications. The corrosion resistance of the coating can be evaluated by means of a salt spray test or a chemical corrosion test.

4. Optical performance

For some applications, the optical properties of the coating, such as gloss and transparency, are also very important. This can be measured by gloss meters and Spectrophotometer s.

Application examples

1. Packaging materials

Aluminum foil coated water-based slurry is widely used in food packaging materials. Water-based coatings can provide good barrier properties to protect food from oxygen and moisture, thus extending shelf life. In addition, the water-based slurry is environmentally friendly and non-toxic, which meets the safety requirements of food packaging.

2. Battery manufacturing

In lithium-ion battery manufacturing, aluminum foil is often used as a current collector. Water-based slurry coating can provide good conductivity and corrosion resistance, ensuring the performance and life of the battery. The experimental coater can precisely control the thickness and uniformity of the coating and improve the overall performance of the battery.

3. Decorative materials

Aluminum foil coated water-based pastes can also be used in decorative materials. Water-based coatings can provide a wide range of colors and patterns to meet different decorative needs. At the same time, the water-based slurry is environmentally friendly and pollution-free, which helps to enhance the environmental image of the product.

4. Protective coating

Aluminum foil-coated water-based pastes can be used as protective coatings, providing corrosion, abrasion, and oxidation resistance. In aviation, automotive and other fields, aluminum foil protective coatings have important application value.

conclusion

The method and application of the experimental coating machine for coating water-based slurry on aluminum foil have a wide prospect and practical significance. High-quality coating results can be achieved through the proper selection of equipment, the optimization of the coating process and the strict control of coating performance. The environmental protection characteristics of water-based slurries have made them widely used in various fields. In the future, with the continuous development and innovation of coating technology, the application of experimental coating machine in aluminum foil coating will be more extensive and deeper.

- 1Application of laboratory coater in LED fluorescent film Spreader

- 2Application and selection of laboratory coater in PDMS thin film prepative

- 3Experimental Study on High Viscosity Ultraviolet Resin Coating on Glass Substrate by Small Coater

- 4Application of doctor blade coater in electrode and solid electrolysis preparation

- 5Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 6Experimental coater application case video of liquid silica gel on release paper

- 7Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 8Several Common Experimental Spreader Methods and Their Applications

- 9Application of laboratory coater coating aluminum oxide paste on PET film