Experimental Application of Automatic Film Applicator on Glass substrates

introduction

With the development of science and technology, coating technology has been widely used in various fields. In particular, coating various functional films on glass substrates, such as filter membranes, conductive membranes, anti-reflective membranes, etc., has become an important research direction of material science and engineering technology. This article will introduce in detail the experimental application of automatic film coating machine for coating filter membrane on glass substrate, covering experimental equipment, material selection, operation steps, result analysis and application prospects.

1. Experimental equipment and materials

1.1 Experimental equipment

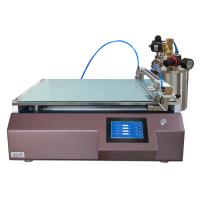

In this experiment, the main equipment used was an automatic film coating machine. The automatic film coating machine has high precision, high efficiency and good repeatability, and is suitable for uniform coating of various coating materials. The following are the specific equipment used in this experiment:

Automatic film coating machine: equipped with a precise film coating head and an adjustable film coating speed and thickness control system.

Drying equipment: constant temperature Drying Oven, used for drying treatment after coating.

Microscope: used to observe and analyze the surface topography and uniformity of the coating film.

Thickness gauge: used to measure the thickness of the coating film.

1.2 Material Selection

In this experiment, a common filter membrane material and a high-purity glass substrate were selected. The specific materials are as follows:

Glass substrate: 100 mm in size × 100 mm and 1 mm thick.

Filter membrane material: polyvinylidene fluoride (PVDF) solution with a concentration of 10%.

2. Experimental procedures

2.1 Base cleaning

Before coating the film, it is very important to clean the glass substrate. Any contaminants or particles can affect the uniformity and adhesion of the coating film. The specific steps are as follows:

Use an ethanol solution to clean the glass substrate to remove oil from the surface.

Rinse the glass substrate with deionized water to remove any residual cleaning agent.

The glass substrate is placed in a constant temperature Drying Oven and dried.

2.2 Film Coating Operation

Preparation of the coating machine: According to the requirements of the coating film, set the parameters of the automatic coating machine, including the coating speed, the thickness of the coating film and the position of the coating head.

Solution preparation: Pour the PVDF solution into the supply tank of the coater to ensure that the solution is free of bubbles.

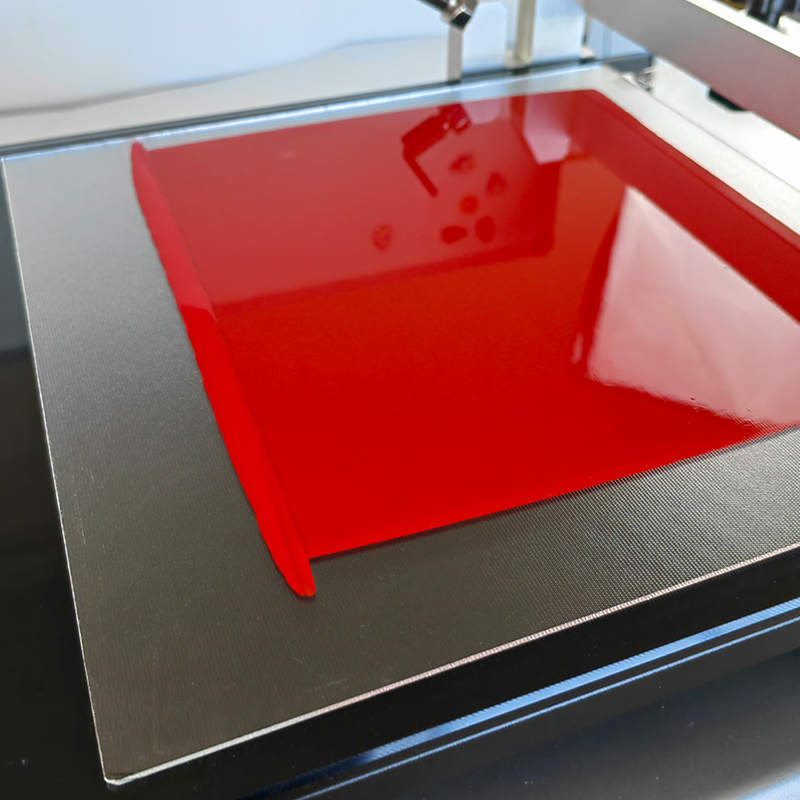

Coating process: The clean and dry glass substrate is fixed on the platform of the film coating machine, and the film coating machine is started for the film coating operation.

Drying treatment: After the coating film is completed, the glass substrate is placed in a constant temperature Drying Oven for drying, and the temperature is set to 60 °C for 1 hour.

2.3 Coating film quality inspection

Surface observation: Use a microscope to observe the surface topography of the coating film to ensure that the coating film is uniform and has no obvious defects.

Thickness measurement: Use a Thickness Gauge to measure the thickness of the coating film to ensure that the coating film thickness meets the predetermined requirements.

3. Experimental results and analysis

3.1 Surface topography

Through microscopic observation, the surface of the coating film is smooth and uniform, and there are no obvious bubbles and particles. This shows that the automatic film coater is able to precisely control the coating thickness and uniformity during the coating process.

3.2 Thickness consistency

The Thickness Gauge showed that the coating film thickness fluctuated in the range of 10±0.5 μm, indicating that the coating film thickness was consistent. This is due to the precise control of the automatic Film Applicator.

3.3 Coating adhesion

The adhesion of the coating film was tested using standard peel test methods, and the results showed that the coating film had good adhesion and was able to adhere firmly to the glass substrate.

4. Discussion

4.1 Optimization of coating film parameters

In this experiment, coating speed, thickness control and drying temperature were important factors affecting the quality of the coating film. By adjusting these parameters, the coating film quality can be further optimized. For example, increasing the coating speed can increase production efficiency, but it may result in uneven film thickness; Appropriately reducing the drying temperature can reduce the stress of the coating layer and improve the adhesion of the coating film.

4.2 Application of different materials

In this experiment, PVDF filter membrane material was selected, which has good chemical stability and mechanical strength. Other types of membrane materials, such as polytetrafluoroethylene (PTFE), polypropylene (PP), etc., can also be coated with a similar coating process. According to the specific application requirements, the selection of appropriate membrane materials and coating process parameters can achieve the preparation of films with different functions.

4.3 Advantages of automatic Film Applicator

Compared to traditional manual coating, automatic Film Applicators offer significant advantages. First of all, the automatic film coating machine can achieve high precision and high repeatability of the coating film, ensuring the consistency and quality of the coating film. Secondly, the automated coating process can greatly improve production efficiency and reduce labor costs. In addition, the parameters of the automatic film coating machine are highly adjustable, which can adapt to the needs of different materials and coating film thicknesses, and has a wide range of application prospects.

V. Conclusions

This article describes in detail the experimental process and results of the automatic film coater coating filter membrane on glass substrate. Experiments show that the automatic film coating machine can achieve high-quality and high-consistency coating film, and has a good application prospect. In future research and application, the coating process parameters can be further optimized, more types of filter membrane materials can be explored, and the preparation and application of multifunctional films can be realized.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application of laboratory coater in LED fluorescent film Spreader

- 4Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 5Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 6Application and selection of laboratory coater in PDMS thin film prepative

- 7Scraping machine selection case: film substrate large size high accuracy scraping solution

- 8Application of Film Applicator in PEM Research and Preparation

- 9Application of Film Applicator in PVDF-HFP Material Research