Experimental test of performance of epoxy resin film coated on metal iron plate by small coater

I. Introduction

Epoxy resins are widely used in coatings, adhesives and composite materials due to their excellent mechanical properties, corrosion resistance and good adhesion. Coating metal iron with epoxy resin can significantly improve the corrosion resistance and mechanical strength of the metal. Therefore, it is of great practical significance to explore the process and coating properties of epoxy resin applied to iron plates. In this paper, we will study the preparation process and performance test of the coating by experimenting with a small coater to coat epoxy resin on iron plates, in order to provide guidance for industrial applications.

2. Experimental materials and methods

2.1 Experimental Materials

Metal iron plate (thickness 0.5mm),Epoxy resin (the main ingredient is bisphenol A type epoxy resin),Curing agent (amine curing agent),Ethanol, acetone.

2.2 Experimental equipment

Experimental Small Coating Machine,ovenElectronic Balances,microscopeTensile testing machines,Potentiostats

2.3 Experimental Procedure

2.3.1 Preparation of epoxy resin coatings

First mix a certain amount of epoxy resin and curing agent in proportion, stir well, and thenAdd the right amount of solvent to adjust the viscosity of the coating to ensure it is suitable for application.

2.3.2 Coating process

1) Clean the iron plate substrate to remove the oil stain and oxide layer on the surface.

2) Use acetone and ethanol to wipe the surface of the iron plate in turn to ensure that the surface is dry and clean.

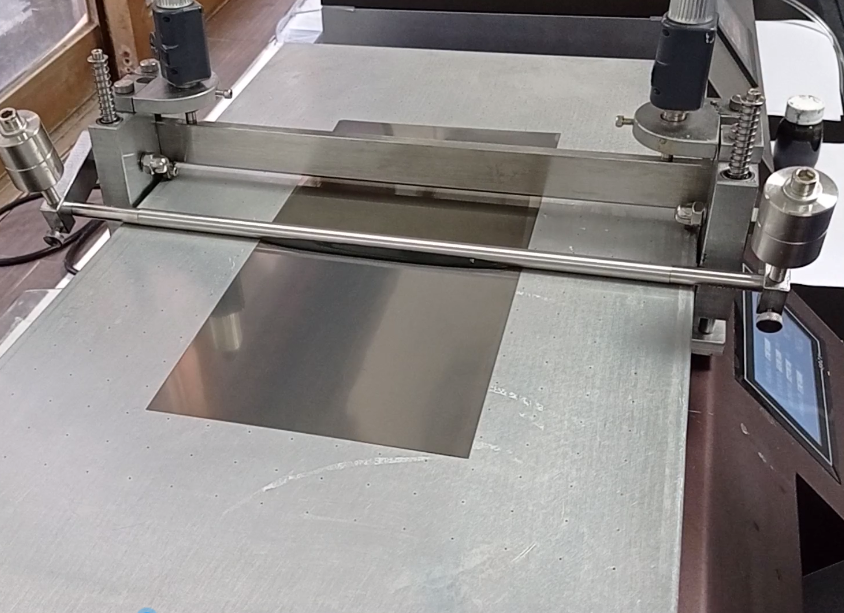

3) Fix the cleaned iron plate on the bench of the experimental small coater.

4) Adjust the coating speed and coating thickness of the coating machine.

5) Turn on the coating machine and evenly coat the prepared epoxy resin coating on the surface of the iron plate.

6) After the coating is completed, the coated iron plate is placed in the drying system for pre-drying.

2.3.3 Curing and post-processing

The pre-dried coated iron plate is placed in an oven and cured at a specified temperature.After the curing is completed, the iron plate is removed and cooled to room temperature.Use a microscope to observe the uniformity and thickness of the coating.

2.4 Coating performance test

Adhesion testA tensile test is used to test the adhesion of the coating.

Mechanical property testingA Tensile Testing Machine is used to test the tensile strength and ductility of coatings.

Abrasion resistance testThe abrasion resistance of the coating is tested using an abrasion Tester.

Anti-corrosion performance testOpen circuit potential (OCP) and electrochemical impedance spectroscopy (EIS) tests are performed by an electropotentiostat.

Thermal stability testThe thermal stability of the coating was tested using a differential scanning calorimetry (DSC) and a thermogravimetric analyzer (TGA).

III. Results and Discussion

3.1 Coating uniformity and thickness control

By adjusting the speed and coating thickness parameters of the experimental small coater, a uniform and controllable thickness epoxy coating can be obtained. Observing the coating under a microscope, it was found that the surface of the coating was smooth and there were no obvious defects. By measuring the coating at different speed and thickness parameters, the optimal coating process conditions were determined.

3.2 Physical property testing of coatings

3.2.1 Adhesion test

A tensile test is used to test the adhesion of the coating. The results show that the optimized coating process results in a coating with strong adhesion and is not easy to peel off. The specific values show that the adhesion of the coating meets the industry standard and can effectively prevent the coating from peeling off.

3.2.2 Mechanical property test

A Tensile Testing Machine is used to test the tensile strength and ductility of coatings. The results show that the coating has high tensile strength and good ductility. This means that the coating has good mechanical properties in practical applications and is able to withstand certain external forces.

3.2.3 Abrasion resistance test

The abrasion resistance of the coating is tested using an abrasion Tester. The results showed that the epoxy coating had excellent wear resistance and remained intact after a long period of friction without significant wear. This property allows it to protect metal substrates for long periods of time in industrial applications.

3.3 Anti-corrosion performance test

3.3.1 Open Circuit Potential (OCP) Testing

Open-circuit potential (OCP) testing is performed by an electropotentiostat. The results show that the iron plate coated with epoxy resin has a high open-circuit potential and shows good corrosion resistance. A higher open-circuit potential indicates that the coating is able to effectively block the intrusion of corrosive media and prolong the service life of the metal substrate.

3.3.2 Electrochemical impedance spectroscopy (EIS) test

Electrochemical impedance spectroscopy (EIS) tests are used to analyze the electrochemical properties of coatings. The results show that the impedance value of the coating is high, indicating that the coating has excellent anti-corrosion performance. The high impedance value means that the coating effectively blocks corrosive media and protects the metal substrate.

3.4 Thermal stability test

3.4.1 Differential Scanning Calorimetry (DSC) test

The thermal stability of the coating is tested by differential scanning calorimetry (DSC). The results showed that the epoxy coating remained stable at high temperatures without significant thermal decomposition. The results show that the coating is stable over a wide range of temperatures, making it suitable for a wide range of industrial environments.

3.4.2 Thermogravimetric Analyzer (TGA) test

The thermal stability of the coating is tested by a thermogravimetric analyzer (TGA). The results show that the epoxy coating has good thermal stability at high temperatures and low weight loss. This result further confirms the thermal stability of the coating and its suitability for applications in high-temperature environments.

3.5 Effect of different coating parameters on coating properties

The influence of these parameters on the coating properties was studied by experimenting with small coaters to adjust different coating parameters (e.g., coating thickness, coating speed). The results show that increasing the coating thickness can improve the mechanical properties and anti-corrosion properties of the coating, but the coating that is too thick will increase the coating difficulty, and the drying and curing time will be prolonged. The coating speed has a significant impact on the uniformity of the coating, and a lower coating speed can result in a more uniform coating, but at the expense of production efficiency. Therefore, it is necessary to find a good balance between coating thickness and speed.

IV. Conclusions

In this experiment, the effects of different coating parameters on the coating properties were studied by experimenting with epoxy resin applied to metal iron plates by a small coater. The experimental results show that the optimized coating process can obtain a uniform and controllable thickness epoxy resin coating, which can significantly improve the mechanical properties and anti-corrosion properties of the metal substrate.Coating thickness and application speed are key factors that affect coating performance. Through experimental studies, suitable coating parameters were determined to ensure better epoxy film performance.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Experimental Study on High Viscosity Ultraviolet Resin Coating on Glass Substrate by Small Coater

- 3Application of doctor blade coater in electrode and solid electrolysis preparation

- 4Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 5Experimental application of water-based paints on film laminating paper by laboratory coater

- 6Laboratory small coater coated with polyester film on ultra-thin PET film [video demonstration]

- 7Technical Requirements and Application of Lithium Battery Slurry Coated on Copper Foil for Small Coater

- 8Application of small coater in gel coating

- 9Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane