Application of laboratory coater coating aluminum oxide paste on PET film

introduction

With the continuous progress of science and technology, functional film materials are more and more widely used in various fields. Due to its excellent physical and chemical properties, PET film is widely used in packaging, electronics, electrical insulation and other fields. As a functional material, alumina (Al₂O₃) is also used in industry and scientific research due to its excellent wear resistance, corrosion resistance and high temperature stability. Homogeneous coating of alumina slurry on PET film can significantly improve its surface properties and expand its application areas. However, achieving this process requires high-precision coating technology. This article will discuss in detail the application of alumina paste coating on PET film by laboratory coaters, focusing on coating equipment, process flow, and key technical parameters.

1. Introduction to laboratory coating machine

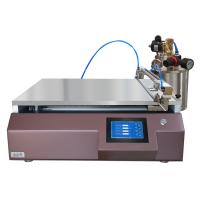

A laboratory coater is a high-precision device that is specifically designed to coat thin film materials on a variety of substrates. TM3200 Vacuum Coating Machine (hereinafter referred to as TM3200 Coating Machine) is an advanced laboratory coating equipment, which can automate the coating operation and improve the accuracy and efficiency of coating. Key features include:

A variety of coating methods: the combination of wire rod and scraper coating methods can adapt to different coating needs.

Vacuum adsorption function: external vacuum adsorption pump to ensure the flatness of the film, suitable for the coating of soft substrates.

High-precision control: the coating speed and coating length can be adjusted freely, and it is equipped with high-precision imported wire rods and scrapers to ensure the uniformity of coating.

Easy to operate: Color LCD touch screen control panel, simple and intuitive operation.

Easy to clean: The clamshell scraper coating head is designed for easy cleaning.

2. Experimental materials and equipment

Substrate: PET film, 200mm×300mm, thickness 50μm.

Coating material: alumina slurry, particle size of 20-30nm, solid content of 30%.

Coating equipment: Huinuo intelligent TM3200 scraper wire rod vacuum coating machine.

Auxiliary equipment: vacuum adsorption pump, Drying Oven, agitator, wire rod, Thickness Gauge, etc.

3. Experimental methods

1. Preparation

First, prepare the materials and equipment you need. Make sure the TM3200 coater is in working order, inspect and clean the applicator head to ensure that there are no residues and contaminants. According to the needs of the experiment, select the appropriate wire rod.

2. Preparation of alumina slurry

Add the alumina powder and an appropriate amount of dispersant to the deionized water, and stir well with a stirrer until a homogeneous alumina slurry is formed. The slurry is treated with an ultrasonic disperser to further disperse the alumina particles evenly. Finally, the slurry is treated with a high-shear emulsifier to ensure the uniformity and stability of the slurry.

3. PET film pretreatment

The PET film is placed on a vacuum adsorption platform and the Vacuum Pump is activated to ensure that the film is flat and free of bubbles.

4. Coating process

The alumina slurry is poured onto the substrate and the appropriate coating parameters are selected. According to the experimental requirements, the coating speed, coating thickness and coating length are set. The coating machine is started, and the alumina slurry is evenly coated on the PET film by combining wire rods and scrapers.

5. Drying and curing

After the coating is completed, the PET film coated with alumina slurry is put into the Drying Oven, and the appropriate drying temperature and time (such as 80°C, 30 minutes) are set to make the solvent in the slurry fully volatilize, and the alumina particles form a dense coating on the surface of the PET film.

6. Coating characterization

Use a Thickness Gauge to measure the thickness of the coating to ensure that it meets the predetermined requirements. Use a microscope to observe the surface topography of the coating and check the uniformity and integrity of the coating. The performance of the alumina coating is evaluated through adhesion tests, abrasion resistance tests, and corrosion resistance tests.

Fourth, the experimental results and discussion

1. Coating thickness and uniformity

The thickness of the coating can be precisely controlled by using high-precision RDS wire rods. The experimental results show that the TM3200 coater can prepare an alumina coating with uniform thickness and smooth surface on PET film. The thickness measurement results show that the coating thickness error is within ±0.001mm, which meets the requirements of high-precision coating.

2. Coating adhesion

The surface energy of the PET film treated with low-temperature plasma is significantly improved, and the adhesion to the alumina paste is enhanced. The adhesion test results showed that the adhesion of the coating reached 4B level, indicating that the bond between the coating and the substrate is strong.

3. Abrasion and corrosion resistance

The test results of the abrasion resistance and corrosion resistance of the coating show that the alumina coating has excellent wear resistance and corrosion resistance. After 500 friction tests, the coating has no obvious wear on the surface and shows good wear resistance. After soaking in acidic and alkaline solutions for 24 hours, the surface of the coating has no obvious change and shows excellent corrosion resistance.

4. Surface topography

The microscopic observation results show that the coating surface is uniform and dense, and there are no obvious bubbles and cracks, indicating that the coating process is stable and reliable. The alumina particles were evenly distributed in the coating without agglomeration, which further verified the uniformity and dispersion of the slurry.

Fifth, the application prospects

Coating alumina slurry on PET film can significantly improve its surface properties and expand its application areas. Specific application prospects include:

Packaging material – The alumina coating gives PET film excellent barrier properties and abrasion resistance, which can be used in high-end packaging materials.

Electronic——The high temperature resistance and insulation properties of alumina coatings make them widely used in the protection and encapsulation of electronic components.

Decorative materials——The alumina coating has good optical properties and decorative effects, and can be used for high-grade decorative materials.

Functional coatings——The antibacterial, anti-corrosion and other properties of alumina coating make it have potential applications in areas such as hygiene.

VI. Conclusions

Through experimental research, the feasibility and superiority of Huinuo Intelligent TM3200 squeegee wire rod integrated vacuum coating machine for coating alumina paste on PET film were verified. The coater has the advantages of high precision, easy operation, and easy cleaning, and can achieve a uniform and dense alumina coating. The experimental results show that the coating thickness is uniform, the adhesion is strong, the wear resistance and the corrosion resistance are excellent, which provides an effective way for the functionalization of PET film. In the future, the coating process and parameters can be further optimized, more functional coating materials can be developed, their application fields can be expanded, and technical support can be provided for the development of related industries.

- 1Application of laboratory coater in LED fluorescent film Spreader

- 2Application and selection of laboratory coater in PDMS thin film prepative

- 3Application of doctor blade coater in electrode and solid electrolysis preparation

- 4Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 5Experimental application of water-based paints on film laminating paper by laboratory coater

- 6Experimental coater application case video of liquid silica gel on release paper

- 7Laboratory small coater coated with polyester film on ultra-thin PET film [video demonstration]

- 8Application of small coater in gel coating

- 9Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane