Automatic Film Applicator and spin coating spin coater: Key technologies and applications in industrial production

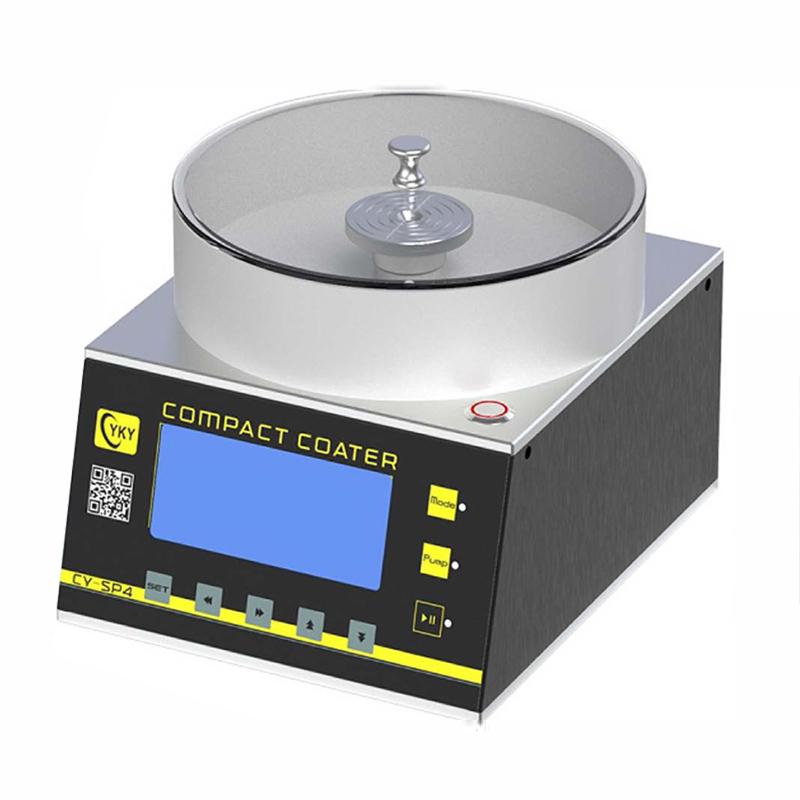

Spin coating homogenizer

The spin coating uniform is a kind of equipment commonly used in industrial production, which is specially used to evenly coat the glue on the surface of the object. Its state-of-the-art operating principle enables precise glue distribution through an efficient gluing process. The procedure is as follows:

The operator places the object to be glued on the table of the Spin Coater.

Press the start button and the machine starts running.

The table starts to rotate, the glue is ejected from the nozzle, and the rotating table evenly distributes the glue on the surface of the object, so as to achieve uniform coating.

The spin coating and blending machine is equipped with an intelligent control system, which can adjust the gluing speed and thickness according to the process requirements to ensure the stability and accuracy of the gluing quality. Its automatic detection function monitors the flow and temperature of the glue, the speed and angle of the table, and thus ensures the effectiveness and quality of the glue. Through these advanced technologies, the spin coating and blending machine has performed well in improving production efficiency and quality control.

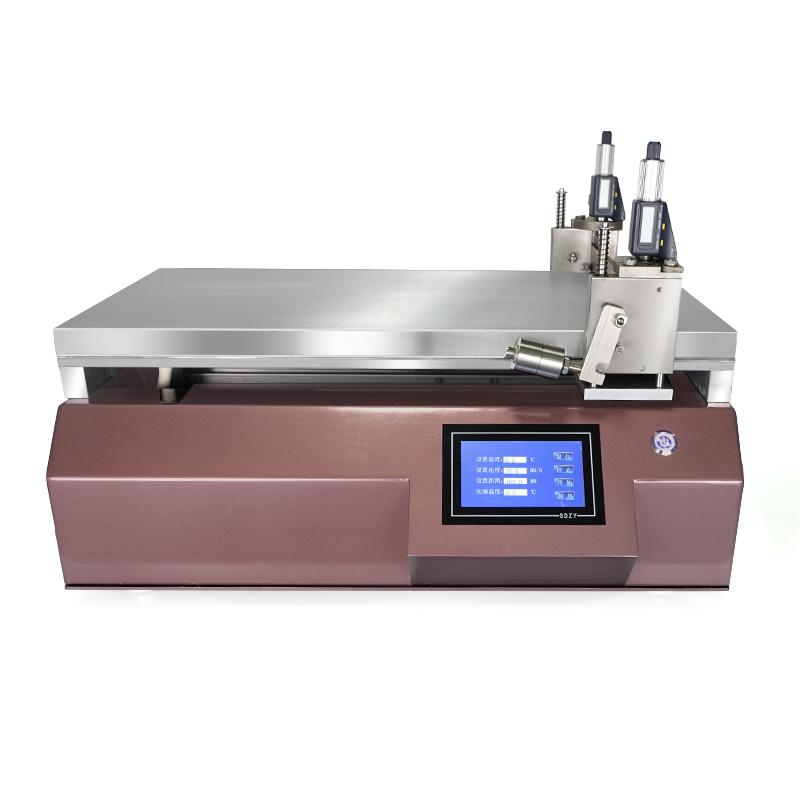

Film applicator

Film coating machine is a kind of mechanical equipment widely used in many industries, and its main role is to form a uniform film on the surface of various materials. Its application fields include electronics, optics, medical, metallurgy and chemicals, etc., and are suitable for the manufacture of various materials and products. The basic structure of the coater includes the following parts:

Feeding system – feeds the raw material to the coating system.

Coating system – Evenly coats the surface of the material by spraying, roller or other means.

Drying system – responsible for drying the paint on the surface of the material.

Discharge system – the surface coating is removed and collected.

Coating technology

According to different experimental needs and material characteristics, the coating machine has a variety of coating methods to choose from. Here are a few common lab coater coating methods in detail.

1. Spin coating method

Spin coating is one of the most common methods of laboratory coating. The principle is to drop a small amount of paint solution in the center of the substrate, and then rotate the substrate at high speed to evenly distribute the paint under the action of centrifugal force and form a thin film. The spin coating method has the following characteristics:

1)The spin coating method can form a homogeneous film in a short time.

2)By adjusting the rotation speed and time, the thickness of the film can be precisely controlled.

3)Suitable for a wide range of substrates and coatings.

2. Scraping method

Doctor Blade Coating uses a squeegee to evenly apply the paint to the surface of the substrate. It is simple to operate and is often used to prepare thicker films. Key features of the squeegee method include:

1)By adjusting the height of the squeegee blade and the viscosity of the paint, the thickness of the film can be controlled.

2)It is suitable for uniform coating of large areas of substrates.

3)No complicated equipment is required, and it is easy to implement in the laboratory.

3. Dip coating method

Dip coating is to immerse the substrate in the coating solution, and after a certain period of time, slowly lift it to form a thin film on the surface of the substrate. Its features are:

1)By controlling the speed of immersion and lifting, a uniform coating can be obtained.

2)It is not only suitable for flat substrates, but also for irregularly shaped objects.

3)It is suitable for coating processes that are repeated many times.

4. Spraying method

Spray coating uses a Spray Gun to spray paint onto the surface of the substrate in a mist. Benefits include:

1)Ability to form a homogeneous coating on irregularly and complexly shaped substrates.

2)By adjusting the spray time and paint concentration, the film thickness can be controlled.

3)It is suitable for both large and small area coating, and the operation is flexible.

5. Casting method

Slot-Die Coating is the uniform casting of the paint onto the surface of the substrate through a slit mold. Its features are:

1)The thickness and uniformity of the paint can be precisely controlled.

2)It is suitable for large-scale continuous production.

3)It is suitable for the coating process of high-viscosity coatings.

6. Roller coating method

Roll coating uses one or more rollers to transfer the paint to a substrate. Features include:

1) It is suitable for large-area continuous coating.

2)By adjusting the drum spacing and pressure, the uniformity of the film thickness can be controlled.

3)Suitable for a wide range of coatings and substrates.

7. Throwing coating method

Spin-Spray Coating combines the advantages of spin-spray and spray coating. The principle is that the substrate is placed on a rotating platform while the paint is sprayed through a Spray Gun. Its features are:

1) The combination of rotation and jetting ensures the uniformity of the film.

2) Able to precisely control the thickness and uniformity of the coating.

3) Suitable for substrates with irregular and complex shapes.

Fields of application

Film applicators play a vital role in many industries:

Electronics industry: Used in the manufacture of transistors and capacitors, these components require a uniform insulation layer to protect the circuit function.

Medical field: Used in the production of artificial joints and dental medical equipment, where abrasion and corrosion resistance are required.

Optics: Coating technology is used to manufacture materials with high transparency and optical properties, such as displays and solar cells.

Packaging industry: The film coating machine provides a protective film for packaging materials, prolongs the shelf life of products, and enhances texture and visual effects.

Printing industry: the coating machine makes the surface of the printed matter smooth and flat, improves the paper texture and waterproof performance, and increases the gloss and color brightness of the printed matter.

Automotive: Provide anti-UV, anti-glare and anti-noise functions for automotive glass, and improve window transparency and brightness.

summary

As important industrial equipment, film coaters and spin coating and blending machines play a key role in different fields. The Film Applicator achieves the protection and functional enhancement of the material surface through a variety of coating technologies and system design. The spin coating and glue leveling machine realizes the uniform coating of glue through intelligent control and efficient operation. These equipment not only improve production efficiency and product quality, but also promote the development of various industries, with the advancement of science and technology, its application prospects will be more extensive, bringing more convenience and comfort to life and work.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Film Applicator in PEM Research and Preparation

- 8Application of Film Applicator in PVDF-HFP Material Research

- 9Application of Film Applicator in Cosmetic Base Body