Application and Experimental Study of Film Coating Adhesive Technology

Adhesives applied to films are a key technology used in packaging, labeling, medical, electronics, building materials, the automotive industry, and household goods. Each application has different requirements for adhesive performance and application process. The thickness of the adhesive coating on the film varies depending on the specific application needs and is typically between a few microns and tens of microns. For example, ziplock bags and plastic wrap coatings in food packaging are typically 5 to 20 microns thick, while industrial packaging coatings for electronic component packaging are between 10 and 30 microns. Medical supplies such as bandages and band-aids are coated with adhesives between 20 and 50 microns thick, while disposable medical devices used for electrocardiogram electrodes are coated between 25 and 60 microns thick. Screen protectors in electronics are typically 5 to 20 microns thick, while flexible circuit boards are between 10 and 50 microns thick. The coating thickness of building materials such as window film and wallpaper is between 25 and 50 microns and 30 and 60 microns respectively, while in the automotive industry the coating thickness of body protection film and window film is between 30 and 100 microns and 20 and 50 microns respectively. Household items such as carpet protectors and furniture protectors have coating thicknesses between 25 and 50 microns and 30 and 70 microns, respectively.

In experimental studies, performance testing is an important step in ensuring the performance of the adhesive on the film. Adhesion test, tensile strength test, weather resistance test, chemical resistance test, heat and cold resistance test, water resistance test, initial tack test, aging test, and air permeability and water vapor transmission rate test are all common test items. Adhesion tests include peel strength tests and shear strength tests, while tensile strength tests evaluate the tensile strength of a film under tensile forces. Weathering tests include UV resistance tests and moisture resistance tests, while chemical resistance tests evaluate the stability of adhesives in chemical environments. Heat and cold resistance tests include heat aging tests and low temperature tests, and water resistance tests such as water immersion tests evaluate the performance of adhesives in water. The initial tack test measures the immediate adhesion of the adhesive, while the aging test, such as the accelerated aging test, simulates the change in performance over time. The Air Permeability and Water Vapor Transmission Rate Test evaluates the air permeability and water vapor permeability of a film, while the Surface Adhesion Test measures the adhesion of the film on the surface of different substrates.

Choosing the right lab coater is critical to studying film application adhesives. Drawdown blade coaters and Spin Coaters are two types of film coaters that are commonly found in laboratories. The squeegee coater is easy to operate, the coating thickness is adjustable, and it has a wide range of applications and low cost. Its high flexibility and affordability make it the preferred choice for laboratory research and is suitable for handling all types of adhesives and substrates. The Spin Coater rotates at high speed to evenly distribute the adhesive on the surface of the substrate, and the coating thickness is very uniform and easy to control, which is especially suitable for high-precision coating of small films, such as the coating of optical and electronic devices. The ease of cleaning of the Spin Coater also makes it suitable for quick changeovers in a wide range of experimental conditions.

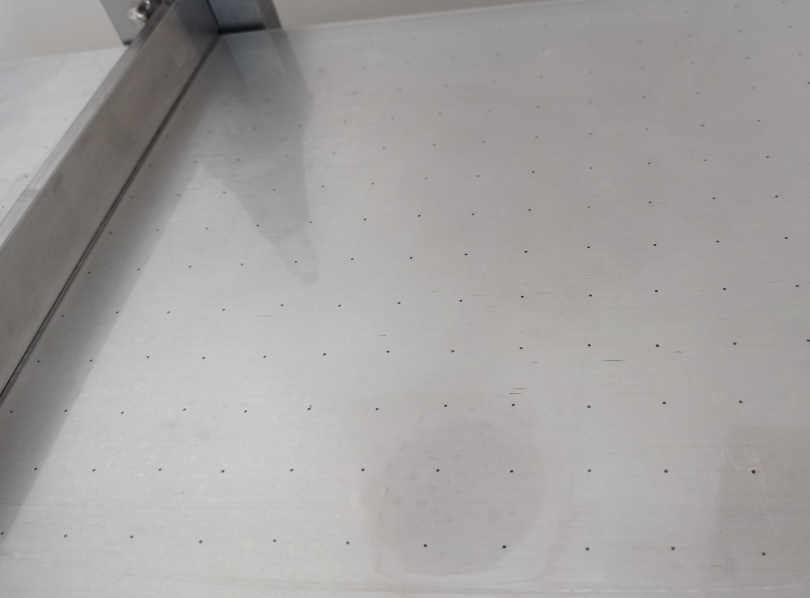

Figure 1: Squeegee coater

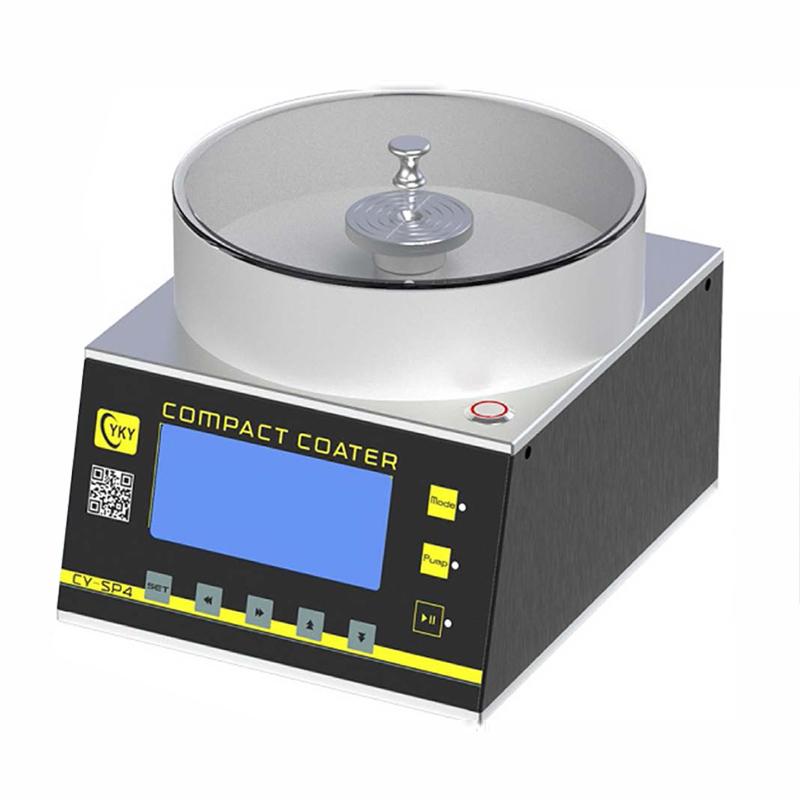

Figure 2: Spin Coater

In the experimental study of adhesives applied to films, a series of technical requirements need to be met. First of all, it is necessary to choose the right film and adhesive to ensure the compatibility and suitability of the material. Secondly, the coating process should ensure uniform coating and appropriate coating thickness to avoid bubbles and impurities. The coating equipment should be selected to suit the specific requirements of the experiment, and the equipment parameters such as coating speed, pressure and temperature should be precisely controlled. Curing and drying conditions also need to be tightly controlled to ensure that the adhesive is fully cured without compromising film performance. In addition, the experimental environment should be kept at a constant temperature and humidity to avoid the influence of environmental changes on the experimental results. Performance testing should be carried out in accordance with standard methods, and data should be accurately recorded and analyzed to ensure the reliability and reproducibility of experimental results. Finally, laboratory operations should follow safety protocols and dispose of waste to comply with environmental requirements.

By applying adhesives to films, a variety of industrial and domestic applications can be realized, and the performance and user experience of products can be improved. Choosing the right laboratory coating machine, strictly controlling the experimental conditions, and ensuring the performance and quality of the adhesive are the keys to promoting the development and application of related technologies.

- 1Film coating thickness measurement

- 2What are the potential applications of diamond and diamond-like carbon films?

- 3What are diamond and diamond-like carbon films?

- 4Preparation of composite films by spin coating

王君涵 - 《大连理工大学》

- 5What is nylon film?

- 6How to paint on PVC surface?

- 7Pressure sensitive adhesive type

- 8Analysis and Countermeasures of Adhesion of UV inks on Film stickers

晓晓 - 《UV 油墨在薄膜不干胶材料上黏着力不良故障分析》