Discussion on film thickness and accuracy in epoxy resin coating

In modern industry and scientific research, epoxy resin is an important coating material, which is widely used in various application scenarios, such as protective coatings, functional coatings, and packaging of electronic devices. In order to meet the high requirements for coating accuracy and uniformity for different applications, it is crucial to choose the right coater and optimized coating parameters.

1. Protective coating application

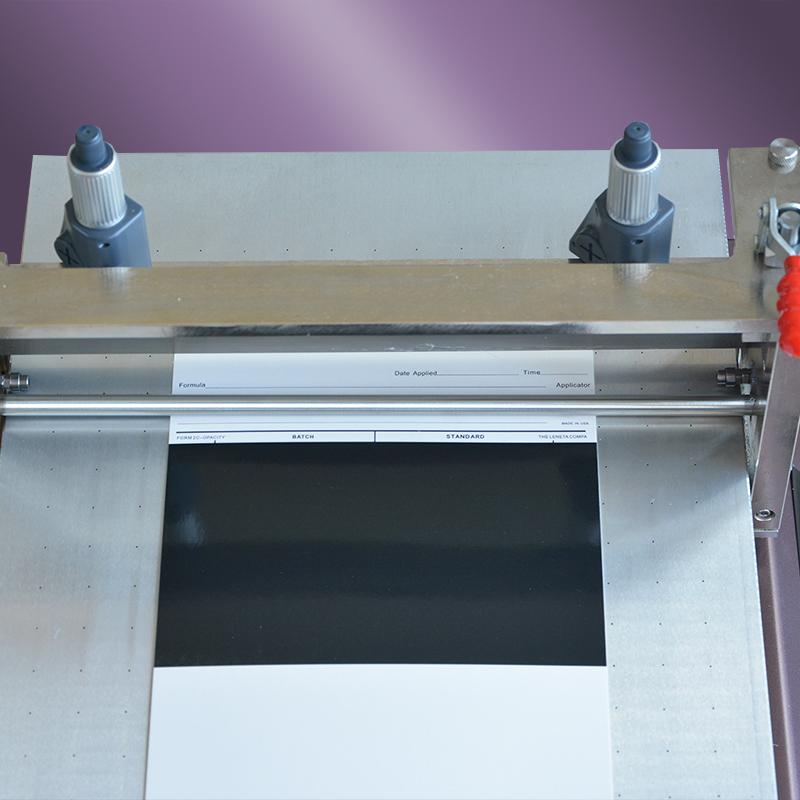

On industrial equipment, coating films with epoxy resins is widely used to provide durability protection. When applying epoxy as a protective coating, it is critical to ensure the uniformity and surface quality of the coating. The wire rod blade applicator is a good choice to achieve coating thicknesses of about 20 to 100 microns, ensuring uniformity of application and surface quality to improve the weathering and chemical resistance of protective coatings.

2. Functional coating application

Epoxy resins are used to prepare coatings with specific functions, such as electrical insulation and wear barriers. These coatings often require the addition of specific fillers or additives to enhance their functional properties. Sprayers have shown advantages in this type of application, with precise control of nozzle design and application parameters, enabling coating thicknesses of approximately 10 to 50 microns and ensuring that the filler is evenly dispersed in the epoxy matrix. This fine coating technology not only improves the mechanical properties of the coating, but also enhances its abrasion and chemical resistance, making it suitable for use in a wide range of extreme environments.

3. Electronic device packaging applications

In the manufacturing process of microelectronic devices, epoxy resins are widely used to encapsulate and protect electronic components. In particular, thin layer coatings with high precision and uniformity are required in these applications. As a common type of coater, the Spin Coater is able to achieve coating thickness control of about 1 to 10 microns by evenly coating epoxy resin on the surface of small devices by rotating at high speed. This precise coating technology not only guarantees the consistency and quality of the coating, but also helps to improve the electrical performance and long-term stability of the electronics.

4. Laboratory research and development applications

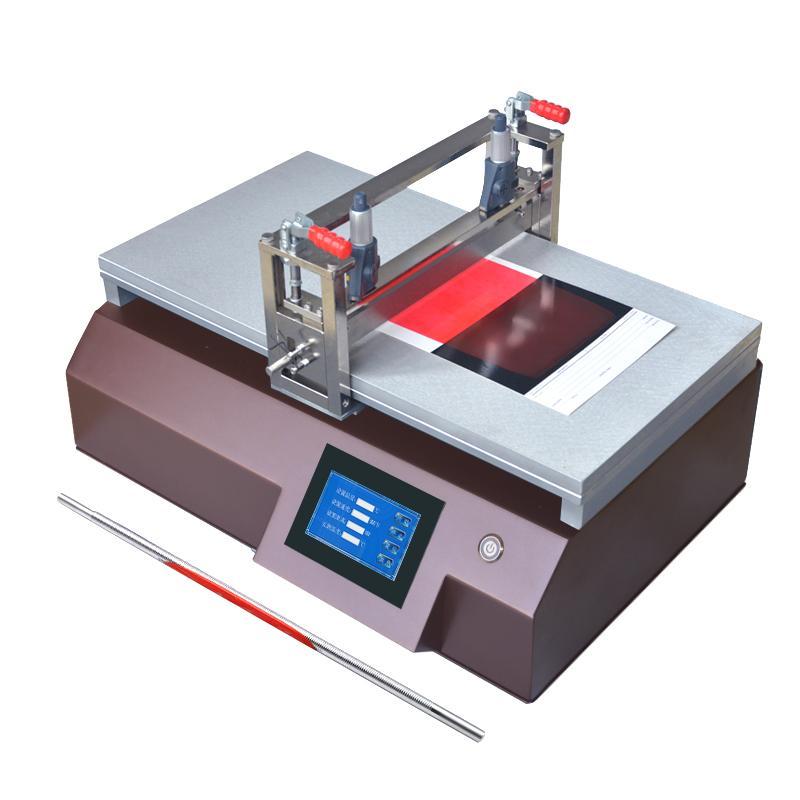

In the environment of a laboratory or research center, film coaters are not only used for production-scale coating, but are also widely used in materials research and new technology development. The multi-functional coater offers flexible adjustment of coating parameters and a wide range of coating material options, capable of achieving coating thicknesses from about 1 to 50 microns, meeting the high requirements of coating thickness, precision and characteristics for different research projects. This advancement in coating technology has not only promoted the development of new materials, but also promoted innovation and improvement in the coating process. The accuracy of the north and south tide line rod coating machine can be as high as 1 micron, and it is widely used in scientific research institutions to do high-precision coating experimental research.

conclusion

By selecting the coater suitable for the specific application needs and optimizing the coating parameters, the coating accuracy and uniformity of epoxy resin on the film can be effectively improved, so as to ensure the stability and reliability of the coating in different application scenarios. Future research and engineering practice should continue to optimize coating technology to meet the increasingly complex and demanding coating needs, and promote the wide application and further innovation of coating technology in various industries.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Film Applicator in PEM Research and Preparation

- 8Application of Film Applicator in PVDF-HFP Material Research

- 9Application of Film Applicator in Cosmetic Base Body