Vacuum oven verification calibrating procedure

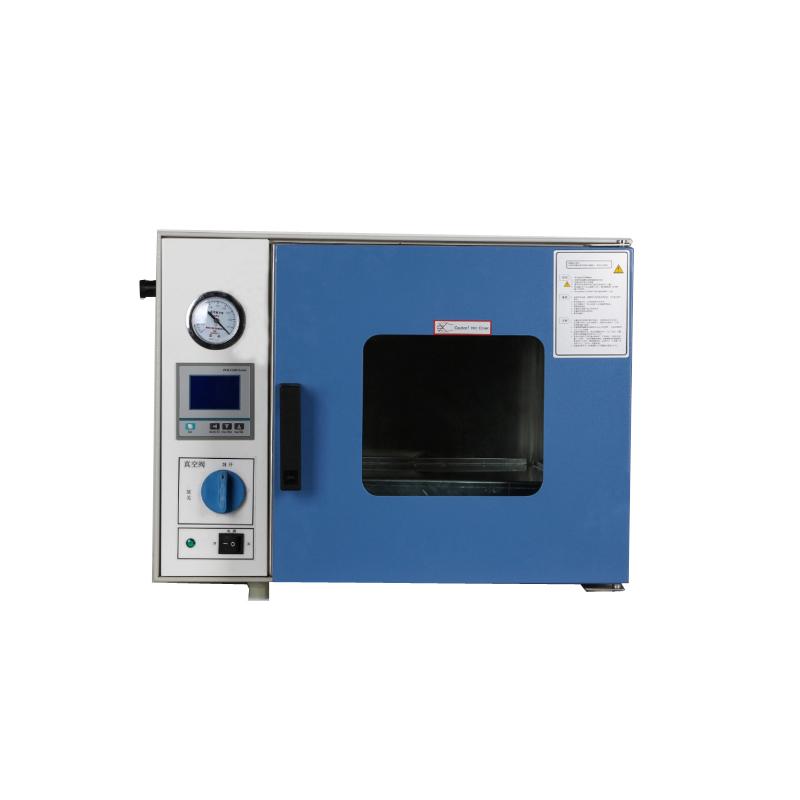

Vacuum Drying Oven is a device used for material drying, removing moisture and other volatile components, which is widely used in scientific research, production and laboratory fields. Its verification procedures are key to ensuring the performance and accuracy of the equipment. The following is a detailed description of the verification procedures for vacuum Drying Ovens:

Vacuum Drying Oven verification procedures

visual inspection,Check whether the appearance of the vacuum Drying Oven is damaged and whether the surface is clean;Check that the door seal is in good condition and that the door opening and closing are flexible.

electrical safety inspection,Check that the power cord, plug and switch are in good condition and that the grounding is good;Check whether the electrical control system is normal, and there are no faults such as short circuit and open circuit.

vacuum system inspection,Check the working condition of the Vacuum Pump to ensure that it can operate normally;Check whether there is air leakage in the vacuum pipeline and whether the sealing performance is good.

temperature control system inspection,Check the working status of the temperature sensor and controller to ensure that the temperature display and control are normal.Calibrate the temperature display of the Drying Oven with a standard thermometer to ensure its accuracy.Tests are carried out at different temperature points (e.g. 50°C, 100°C, 150°C) and the temperature error is recorded.

vacuum test,The ultimate vacuum of the Drying Oven is measured using a standard vacuum gauge and the difference between the actual value and the nominal value of the equipment is recorded.The test was carried out under different vacuum degrees (such as 500Pa, 100Pa, 10Pa), and the vacuum degree error was recorded.

constant temperature performance test,At the set temperature, keep the temperature constant for a period of time (e.g., 1 hour) and record the temperature fluctuation range.Ensure that the constant temperature performance meets the requirements of the technical specifications of the equipment.

uniformity test,Multiple temperature sensors are placed inside the Drying Oven to measure the temperature at different locations.The temperature of each point is recorded, the temperature uniformity is calculated, and the temperature difference of each point is within the allowable range.

time control system check,Check the working status of the time controller to ensure that the time setting and control are accurate.Perform a timing test and record the time error.

drying performance test,An actual drying test was performed to test the drying time and effect of the sample.The weight before and after drying is recorded and the drying efficiency is calculated.

Reference standards

GB/T306472014 Laboratory Electric Heating Constant Temperature Drying Oven;

JJF11012003 Verification procedures for vacuum measuring instruments;

GB/T2900.332008 Electrical terminology instruments, meters and related devices.

Precautions

Regular verification, the vacuum Drying Oven should be verified regularly, generally once a year, to ensure its long-term stable operation.

Professional operation, the verification work should be carried out by professionals to ensure the accuracy and standardization of the verification process.

Record keeping, the verification results should be recorded in detail, and the verification report should be saved for reference.

By strictly following the above procedures, the performance and accuracy of the vacuum Drying Oven can be ensured, so as to ensure the reliability of the experiment and production.

-

-

-

-

-

-

-

CHINA DZG-6090 Vacuum Oven 1500W/90L$ 1185.00

-

-