Several Common Experimental Spreader Methods and Their Applications

In the field of materials science and engineering, coating technology is a key surface treatment method that is widely used in laboratory research and engineering development. Different coating methods have their own characteristics and are suitable for different application needs and material properties. In this article, we will discuss several common laboratory coating methods and their specific application scenarios and key technical parameters.

Manual coating is one of the most basic coating methods, usually using tools such as wire rods or wet film preparers to evenly coat the paint onto the surface of the substrate. This method is simple and intuitive to use, making it ideal for small-scale experiments and preliminary feasibility studies. Although the thickness and uniformity of manual coating are influenced by the skill and experience of the operator, its simplicity and intuitiveness make it widely used in the laboratory, such as rapid sample preparation or exploratory studies.

Spin coating is a high-precision coating method that is particularly suitable for applications that require coating uniformity and thickness control. During rotational coating, the substrate is placed on a rotating table and the paint is applied from the center point, distributing the coating evenly as it rotates. This method is widely used in semiconductor device fabrication, optical thin film fabrication, and nanomaterial coating, and is favored for its ability to achieve highly uniform and precise coating results.

Spray coatings are suitable for large-area applications and applications that require fast application, such as paint coating in the automotive industry and applications of anti-corrosion protective coatings. Spraying the paint evenly on the substrate with a Spray Gun is able to effectively cover complex-shaped surfaces and control a wide range of coating thicknesses. The key to spray coating is the spray pressure of the Spray Gun, the spray distance and angle, as well as the concentration and viscosity of the coating, which directly affect the uniformity and quality of the coating.

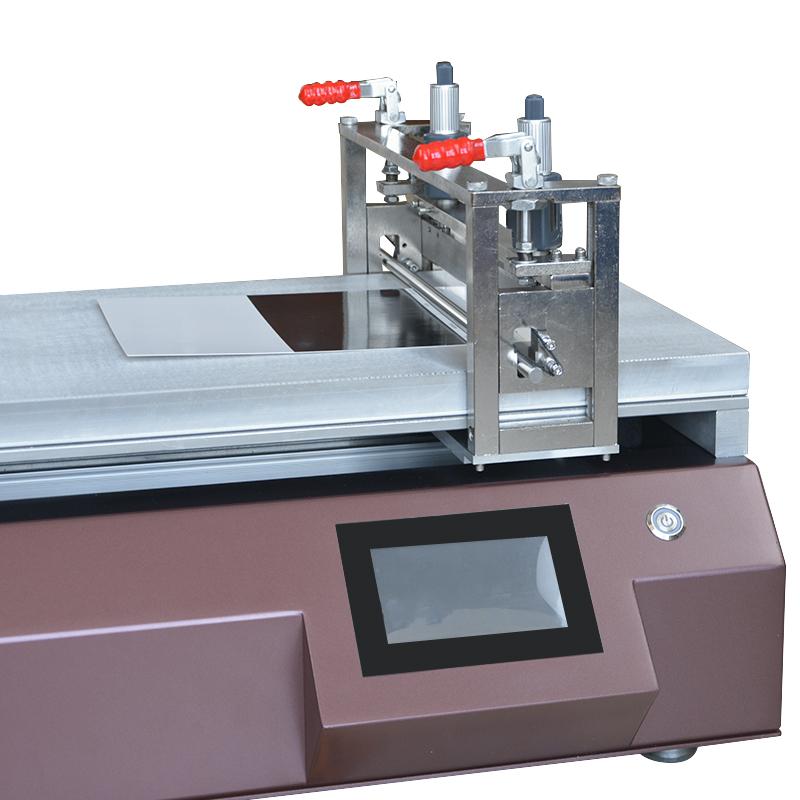

Scraping coatings use a squeegee to scrape off excess paint on the surface of the substrate to create a uniform coating layer. This method is suitable for the preparation of organic solar cells in flexible electronic devices that require a thick coating layer or coatings with a certain viscosity.Straightness of the scraper,The gap between the blade and the substrate and the coating speed are key parameters that affect the thickness and uniformity of the coating layer and need to be adjusted according to the rheological properties of the coating and the desired coating thickness.

Finally, roller coating is suitable for large-scale and continuous production coating methods, where the paint is evenly applied to a flexible substrate by means of a roller. This method is widely used in the manufacture of flexible electronics, the fabrication of solar panels, and high-speed continuous production. The material and surface properties of the drum, the coating speed, and the viscosity and rheological properties of the coating are important parameters that affect the uniformity and quality of the coating.

In conclusion, different coating methods have their own unique applications and advantages in the laboratory and engineering. The selection of the appropriate coating method should comprehensively consider the experimental purpose, the characteristics of the coating object and the performance requirements of the required coating layer, so as to achieve a good coating effect and application effect. The development and application of coating technology will continue to drive innovation and advancement in materials science and engineering.

- 1Application of Mayer Rods in protective coating prepative

- 2Application and selection of laboratory coater in PDMS thin film prepative

- 3Application of Mayer Rods in 2D Single Crystal Copper Nanosheet Films

- 4Application of doctor blade coater in electrode and solid electrolysis preparation

- 5Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 6Application of Mayer Rods in composite coating prepative

- 7Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 8Application of laboratory coater coating aluminum oxide paste on PET film

- 9Experimental test of performance of epoxy resin film coated on metal iron plate by small coater