Influencing Factors of Glue Coating on PET Film for Small Film Applicators

In this paper, the process and effect of a small film coater on polyethylene terephthalate (PET) film with glue were studied. Through the experiments of different configurations of the coating machine, the effects of coating speed, coating thickness, coating temperature and other parameters on the coating quality were analyzed. The results show that the optimized coating film configuration can significantly improve the uniformity and adhesion of the coating, and provide reliable technical support for the application of PET film in electronics, packaging and other fields.

Due to its excellent mechanical properties, chemical stability and transparency, PET film has been widely used in packaging, electronics, optics and other fields. In order to improve the performance of PET film in different applications, it is often necessary to coat its surface with a functional material. As an important coating material, glue can provide adhesion and protection for PET films.

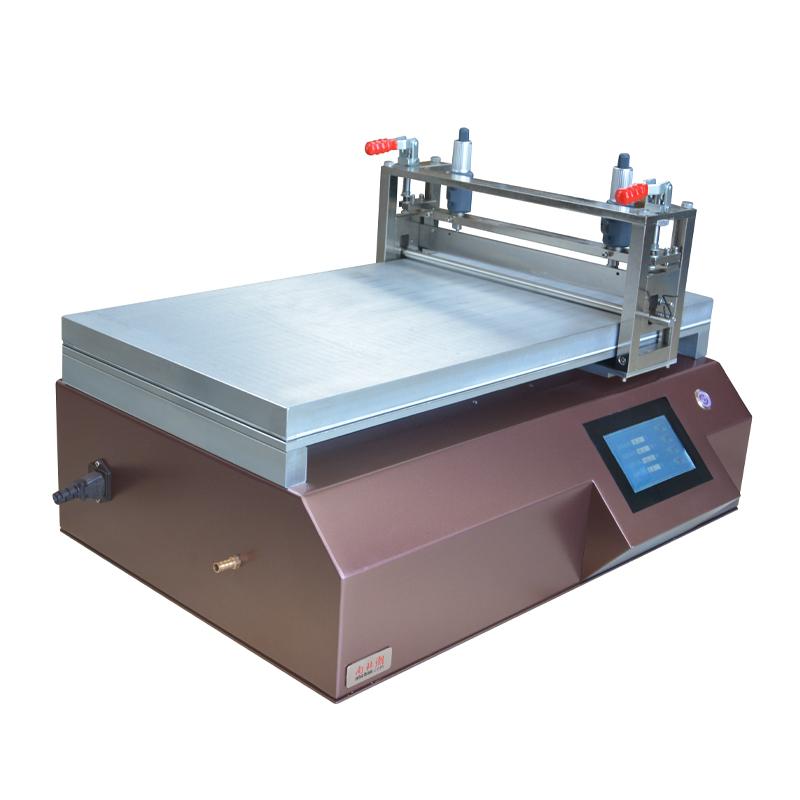

The small film coater is a kind of high-precision laboratory coating equipment, which is suitable for laboratory coating film proofing. In this paper, the influence of the process parameters of glue coating on PET film by small film coater on the coating performance was studied through systematic experiments, in order to provide guidance for actual production.

Experimental part

Materials & Equipment

Substrate: PET film, thickness 50 microns.

Coating: industrial glue, the main component is polyvinyl alcohol.

Equipment: Small film coating machine, automatic film coating machine with vacuum adsorption function, with adjustable coating speed, coating thickness and coating temperature.

Experimental Methods

Substrate treatment: Cut the PET film into 10cm ×10cm size, wash it with ethanol to remove dirt and grease on the surface, and dry it for later use.

Coating process:

Coating speed: 5mm/s, 10mm/s, 15mm/s.

Coating film thickness: Three wire rods with different rod numbers are selected, and the coating film thickness is 3 microns, 6 microns and 9 microns respectively.

Coating temperature: set to 20°C, 40°C, 60°C.

Test Method:

Coating thickness: Measured with a laser Thickness Gauge.

Coating uniformity: Observed by light microscope.

Adhesion test: 100-grid test is adopted.

data analysis

The experimental data were analyzed by Excel and Origin software, and the influence of each parameter on the coating performance was plotted.

Results & Discussion

1. The influence of coating speed on coating quality

Experiments show that the coating speed has a significant effect on the thickness and uniformity of the coating. When the coating speed is low (5mm/s), the coating is thicker and the uniformity is better; As the speed increases, the coating thickness gradually decreases, but the uniformity decreases. This is due to the fact that at higher speeds, the glue does not spread enough time on the surface of the substrate, resulting in uneven coating.

Specifically, when the coating speed is 5 mm/s, the coating thickness is 9.5 microns, and the uniformity is good, when the speed is increased to 10 mm/s, the coating thickness is reduced to 7.8 microns, and when the speed is further increased to 15 mm/s, the coating thickness is 6.3 microns, and the uniformity is reduced.

2. The influence of coating film thickness on coating quality

Coatings exhibit different properties at different film thicknesses. When the thickness of the coating film is 3 microns, the coating is thinner and has better uniformity, but the adhesion is poor; When the thickness is increased to 6 microns, the adhesion of the coating is significantly improved, and the uniformity is still good. As we continue to increase to 9 microns, the coating uniformity decreases, but the adhesion reaches a good state. This indicates that a moderate coating film thickness helps to balance the uniformity and adhesion of the coating.

The specific experimental data show that when the coating film thickness is 3 microns, the coating adhesion score is 3 points (out of 5 points); The adhesion score increases to 4.5 for a thickness of 6 microns, and for a thickness of 9 microns, the adhesion score reaches 5 and the coating uniformity score is 4.

3. The influence of coating film temperature on coating quality

The coating film temperature has an important influence on the degree of curing and adhesion of the coating. The experimental results show that at a lower coating temperature (20°C), the coating cures incompletely and the adhesion is poor. As the temperature increases, the coating gradually cures completely, and the adhesion improves significantly. When the temperature reaches 40°C, the coating performancegood; When the temperature continues to rise to 60°C, the coating performance is not further improved, and there is a risk of thermal deformation of the substrate.

The specific experimental data show that when the coating film temperature is 20°C, the coating adhesion score is 3.5 points, when the temperature is increased to 40°C, the adhesion score is increased to 5 points, and when the temperature is further increased to 60°C, the adhesion score is still 5 points, but the thermal deformation score of the substrate is 2 points (not ideal).

Comprehensive discussion

Through the analysis of the above experimental results, the optimized coating process parameters are as follows: coating speed 5mm/s, coating film thickness 6 microns, and coating film temperature 40°C. Under these conditions, the coating has:gooduniformity and adhesion to meet the needs of practical applications. In addition, process stability and equipment maintenance in actual production need to be considered to ensure the continuous stability of coating quality.

In the course of the experiment, some noteworthy problems were also discovered. For example, air bubbles may appear during the coating process, which can affect the uniformity and adhesion of the coating. The solutions to this problem include: optimizing the coating device of the film coater, improving the glue formulation, adding the degassing process, etc.

conclusion

In this study, the influence of the process parameters of the small film coater on the coating performance of PET film was investigated through systematic experiments. The results show that the coating speed, coating thickness and coating temperature are the key factors affecting the coating quality. The optimized coating process parameters are the coating speed of 5 mm/s, the coating thickness of 6 microns, and the coating temperature of 40 °Cgooduniformity and adhesion.

Tips: The experimental results may vary due to different materials, and the experiment is for reference only.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Film Applicator in PEM Research and Preparation

- 8Application of Film Applicator in PVDF-HFP Material Research

- 9Application of Film Applicator in Cosmetic Base Body