The principle and application of miniature coil spraying machine

The micro coil spraying applicator is a kind of equipment specially designed for coil surface coating treatment, and its small and delicate structure and efficient operation mode make it popular in various industries. This article will introduce its working principle, application field, structural characteristics, operation method and precautions in detail in detail.

How it works

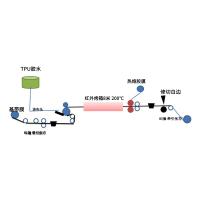

The micro coil spraying coater sprays the paint evenly on the surface of the coil through high-pressure spraying technology, resulting in a uniform coating. The working principle of the micro coil spraying applicator is based on high-pressure spraying technology, which sprays the paint evenly on the surface of the coil through a nozzle, resulting in a uniform coating. First, the coil is fed into the coater via a feeding device. The paint is then conveyed through a feeding system to the spraying unit. Under high pressure, the paint is atomized and evenly sprayed on the surface of the coil through a nozzle, ensuring the uniformity and consistency of the coating. After the spraying is completed, the coil enters the drying device for drying treatment, so that the coating cures quickly. Finally, the dried coil is rolled into a roll by a winding device, which is convenient for subsequent processing or storage. The entire process is precisely controlled by an advanced control system that adjusts spray pressure, paint flow and coating thickness to meet different application needs. Compact, easy to operate, and highly automated, it is suitable for many types of coatings and substrates, making it a good choice for efficient coating processing in small production lines and laboratories.

Fields of application

This equipment is widely used in a variety of industries such as electronics, automotive, medical devices, packaging, and textiles. For example, in the electronics industry, it is used to manufacture surface coating treatments for circuit boards and electronic components; In the automotive industry, it is suitable for coating processing of automotive interior materials and seals; In the medical field, it is used to coat medical devices and sanitary products; In the packaging industry, it is used for the coating treatment of food packaging materials and paper; The textile industry uses it to treat textiles with waterproof, oil-repellent and anti-fouling coatings.

Structural features

The compact design of the micro coil spraying coater has the following notable features:

The equipment is small in size and occupies a small area, which is suitable for small production lines and laboratory use.

Equipped with an advanced control system, it is able to precisely control the thickness and uniformity of the coating.

It can handle many types of coatings and substrates to suit different process needs.

It has the functions of automatic feeding, spraying, drying and winding, and the operation is simple and efficient.

Environmentally friendly coatings and high-efficiency drying systems are used to reduce environmental pollution.

How it works:

When using a micro coil spray coater, follow these steps:

Inspect all parts of the equipment to ensure that the paint and coil are ready.

Set appropriate spraying parameters, such as spraying pressure, paint flow, coating thickness, etc.

Power on the device and follow the instructions on the operation panel to set and adjust.

Load the coil into the feeding unit and make sure it runs smoothly.

Activate the spraying device to ensure that the paint is evenly sprayed on the surface of the coil.

Observe the spraying effect and adjust the spraying parameters if necessary to ensure that the coating is uniform and consistent.

After the spraying is completed, the coil enters the drying device for drying.

After confirming that the coating is completely dry, rewind the coil and complete the operation.

Precautions for use

During use, the following points need special attention:

Before operation, you should read the equipment instruction manual carefully to understand the safety precautions.

Wear the necessary protective equipment during operation, such as protective gloves, goggles, etc.

Choose the right coating for your application to ensure that it is compatible with the substrate and meets environmental requirements.

The paint should be stirred thoroughly before use to avoid sedimentation and agglomeration.

Regularly clean and maintain the equipment to ensure the proper operation of all components.

Wear parts are regularly inspected and replaced to avoid equipment failures affecting production.

The equipment should be installed in a well-ventilated environment to avoid the harm caused by paint volatiles to human health and the environment.

Keep the work area clean to avoid paint spillage and contamination.

In conclusion, the micro coil spraying coater is a high-efficiency and precise coating processing equipment that can significantly improve production efficiency and product quality through correct operation and maintenance. Whether in the laboratory or in industrial production, it shows irreplaceable advantages.

- 1Systematic understanding of coil isolation film coater

- 2Analysis of PVC coil composite coater technology

- 3Analysis of extrusion hot-melt adhesive coater technology and comparative study of coil hot-melt adhesive coater

- 4Detailed explanation of heating coil coater technology and introduction of heating system

- 5Comparison between hot-melt adhesive double-sided coater and hot-melt adhesive coil coater

- 6Epoxy coil coater technology and selection method

- 7Selection method and maintenance technology of waterproofing membrane coater

- 8Polymer coil coater vs sheet coater: technology showdown

- 9Self-adhesive coil coater technology principle, operation and maintenance